My experience with supplier websites sometimes exposed risks hidden in plain sight. These website signs help me spot unreliable suppliers before wasting resources.

If a supplier does not list clear contact info, factory qualifications, customer reviews, and detailed product specs, I’m cautious. I avoid sites with suspiciously low prices, poor design, lack of company address, or generic product photos.

These website checks help me avoid unreliable suppliers and secure high-quality undercarriage parts safely.

Should I be concerned if a website offers a huge variety of unrelated products?

A broad product range raises questions about focus and expertise. Many unrelated items can signal a trading company, not a manufacturer.

Yes, a huge range often suggests a trading company or scattergun approach without deep expertise. Manufacturers usually specialize. If parts vary too much, quality may lack.

Assessment of product variety

When browsing, I check if the supplier lists not just undercarriage parts but also totally different categories like electronics, clothing, or furniture. This spread indicates a trading setup. I question their focus on quality and compliance in bulk manufacturing 1.

Manufacturers specialize in machinery or specific components. A true undercarriage parts producer concentrates on related items: rollers, sprockets, idlers, chains, and shoes. They publish detailed machining, hardening, and assembly specs.

Key indicators to check

| Indicator | Concerning Sign | Good Sign |

|---|---|---|

| Product Range | Widely varied categories, unrelated to main items | Consistent focus on specific machinery parts |

| Technical Specifications | Lack of clear engineering detail | Detailed technical specs, materials, sizes |

| Certifications | No visible ISO, CE markings on products | ISO9001, CE, and relevant industry certifications |

Practical tips to uncover focus

- Check company brochure or catalog. True manufacturers show tech data and specs.

- Request an ISO certification 2 tied to production of listed items.

- Visit LinkedIn 3 or professional profiles to confirm their industry expertise.

Is a lack of detailed factory photos or videos a warning sign?

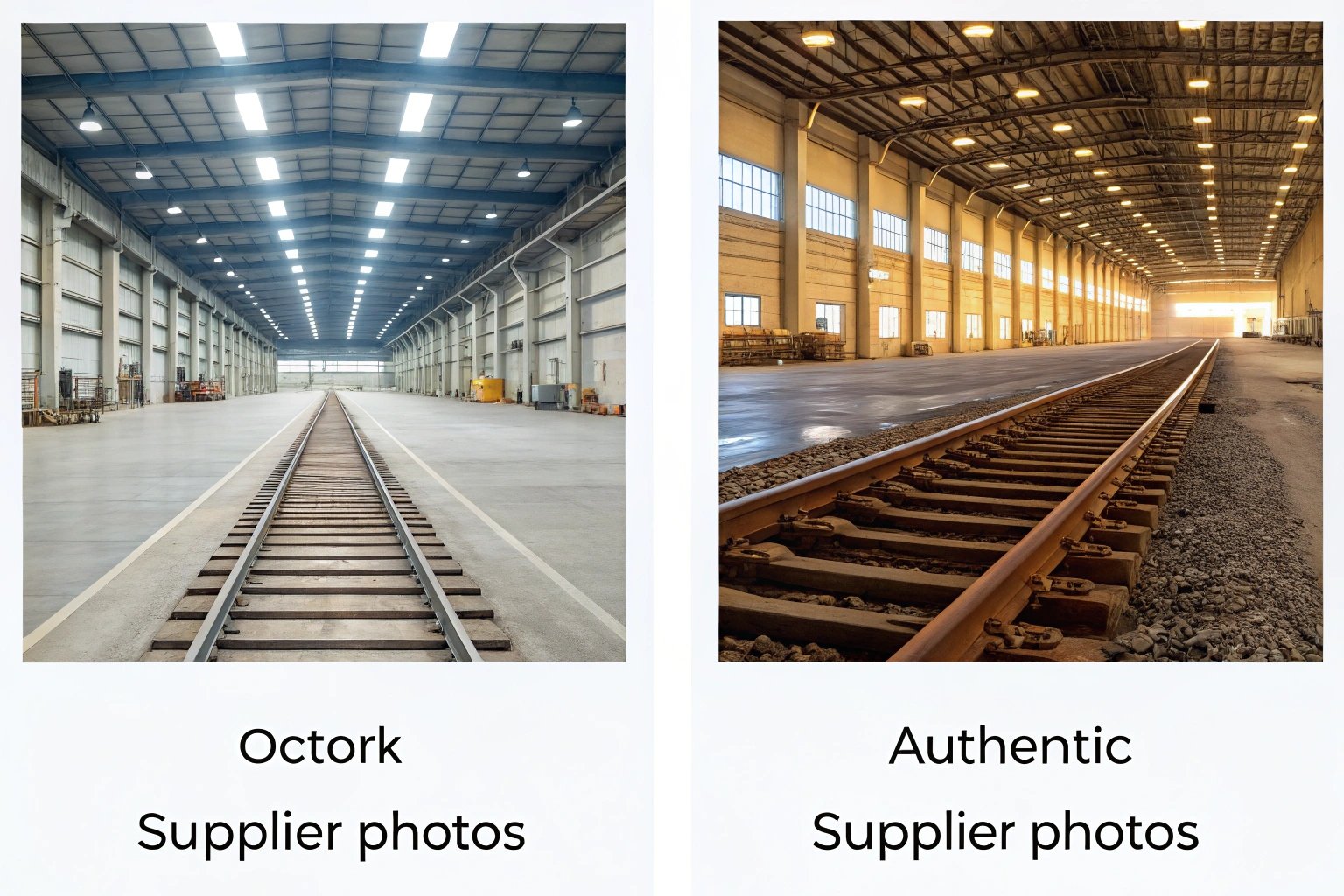

Yes, clearly missing visual proof of facilities is concerning. Real factories invest in transparency, showing confidence in operations.

Missing or generic factory images signal risk. Lack of live footage invites doubt about their actual operations or capabilities.

Checking visual authenticity

A supplier should have clear factory photos and videos showing lathes 4, press lines, hardening setups, assembly areas, and shipping docks. Lack of these images point towards possible trading intermediaries instead of direct producers.

If galleries look generic or seem stock, I ask for real-time video calls to verify setup. Multiple facility angles increase confidence.

Visuals to expect

| Visuals | Concerning Sign | Good Sign |

|---|---|---|

| Factory Images | Stock look, poor quality, no machinery shown | High-resolution photos of operations, site view |

| Facility Footage | No video or generic clips | Live or dated video showing workers, active lines |

| Machinery Display | Too simple or absent images | Array of active CNC machines, presses, treatment units |

Field tips for confirming facility

- Request live video tours with supervisors.

- Ask for posts on industry networks 5 showing shop events.

- Require machine capacity 6 lists, confirming power and model.

How can I tell if the product photos they use are theirs or just stock images?

I look for real depth, variety, and uniqueness. Stock images show patterns that real footage breaks with specifics.

Routine repeats or high polish suggest stock images. Real supplier images capture depth, variety, and unique process context.

Product photo scrutiny

When browsing, check consistency. Repeated polish with no variety or contextual background signals stock use. Makers mix detail, showing unique part angles, lines, workers, and textures.

Stock often misses these dynamics. They save fast looks, but thorough checks map details and personals. Unique settings and individualized depth is the differentiator.

Pattern checks in photos

| Photo Element | Concerning Sign | Good Sign |

|---|---|---|

| Angles | Repetitive, generic poses | Varied angles showing unique identifiers |

| Background | Consistently generic or too clean | Diverse backdrops hinting factory context |

| Details | Lack of visual depth, flat imagery | High-focus details showing textures, working conditions |

Practical recognition strategy

- Request fresh snapshots with visible date stamps 7.

- Ask for personal sourcing cases, showing real deliveries.

- Verify part dimensions or production context 8 that stock misses.

What are the signs that I might be dealing with a trading company disguised as a manufacturer?

Business structure, product scope, and website feel offer clues. Disguise risks mean moving cautiously if these appearances show.

If wide product range, shallow tech content, and uncertain site design appear, consider trading risk. Request evidence of manufacturer status directly.

Trading risk features

When browsing, distinct patterns across scope and structure suggest trading risk. Lack of deep site spec or poorly laid product layout add warning. True manufacturers show detail inside consistent focus, tech layout, and cert depth.

If board list is broad, or unclear plan details arise, trading risk 9 raises. A solid production mission with visible standards resists this.

Indication patterns

| Feature | Trade Disguise Risk | Manufacturer Assurance |

|---|---|---|

| Product Scope | Diverse listings across sectors | Focused engineering specs, consistent machinery parts |

| Site Design | Poor layout, unnatural interface | Professional, dedicated, detailed design |

| Technical Content | Generic specs | Clear engineering, metallurgy, assembly procedures |

Proof search approach

- Request facility contract, proving long-term setup.

- Ask for production timeline, proving sequential consistency.

- Require material cert 10, showing processing route and compliance detail.

Conclusion

Supplier websites reveal hidden risks with distinct signs. Analyze design and content craftsmanship, and assess if manufacturing dynamics and visual depth prove genuine.

Footnotes

1. Explanation of mass production and its impact on manufacturing consistency. ↩︎

2. Official guide to ISO 9001 standards for quality management systems. ↩︎

3. Professional networking platform to verify company history and employee expertise. ↩︎

4. Overview of lathe machinery used in the production of metal components. ↩︎

5. Resource for finding and verifying North American industrial suppliers. ↩︎

6. Guide to calculating and understanding the output limits of manufacturing machinery. ↩︎

7. Methods for adding time and date metadata to digital photographs. ↩︎

8. Definition of discrete manufacturing processes used in machinery part production. ↩︎

9. Academic overview of risks associated with trading and supply chain intermediaries. ↩︎

10. Access to international standards for materials testing and certification. ↩︎