Are you worried about future equipment compatibility? Technology is changing very fast. As a manufacturer, I see five key trends emerging in undercarriage tech that you need to know about.

The 5-year outlook for excavator undercarriage technology involves the integration of advanced materials for durability 1, IoT sensors for predictive maintenance 2, and energy-efficient designs 3 to support electric machinery and environmental standards. Manufacturing will see more automation and AI optimization.

These changes are not just ideas; they are happening in R&D labs right now, including my own at Dingtai. As a purchasing director, understanding how we are preparing for this helps you plan your future inventory. Let's look closer at what this means for the parts you buy.

What new materials or manufacturing processes do they see becoming more common?

Are you tired of parts wearing out too fast in tough conditions? Standard steel cannot handle every job site. We are heavily invested in new materials and processes to solve this problem.

New materials becoming common include high-strength, low-alloy (HSLA) steels 4, advanced composite materials 5 for weight reduction, and enhanced wear coatings. Manufacturing processes are shifting toward automated friction-stir welding, advanced heat treatments, and additive manufacturing (3D printing) 6 for custom prototypes.

As a buyer like David, I know your biggest pain point is premature failure. When a track roller fails, your customer's machine stops, and you get the angry call. My technical team at Dingtai believes the future isn't just stronger steel; it's smarter materials and processes.

Advanced Materials: Beyond Basic Steel

For 20 years, we’ve relied on hardened steel (like 40Mn or 50Mn) with specific heat treatments. This is still the standard and performs very well. But our R&D team is constantly testing new formulas. The goal is to increase wear resistance without making the part too brittle, which can lead to cracks.

- High-Strength Alloys: We are seeing more use of alloys mixed with boron and other elements. These create a deeper hardness layer during heat treatment. This means the part resists surface wear much longer, especially in abrasive conditions like sand or rock.

- Composite Materials: This is still experimental for heavy-load parts like rollers. However, it is very promising for non-structural components like track guards. Composites can reduce weight significantly, which is a big advantage for fuel or battery efficiency.

- Enhanced Coatings: We are also exploring thermal spray coatings. Think of it as adding a super-hard "skin" to a standard part. This can be a cost-effective way to fight wear in specific high-friction zones, extending the life of the base component.

New Manufacturing Processes

How we make the part is changing just as fast as the material. For a technical buyer, the process is what guarantees quality consistency. This is often your biggest concern.

- Additive Manufacturing (3D Printing): Right now, 3D printing heavy steel parts is too slow and expensive for mass production of rollers or chains. But we are using it for rapid prototyping. If you need a custom-designed idler for a special mining application, we can design, print a prototype, and test it (using digital simulations) faster than ever. For complex, low-volume replacement parts, this will become very common.

- Automated Quality Control: Your frustration with inconsistent batches is valid. This is why we are investing heavily in automated QC 7. Instead of just spot-checking, we are moving to 100% automated ultrasonic testing and magnetic particle inspection right on the production line. A scanner checks every single part for tiny internal cracks before it gets heat-treated. This eliminates human error. It ensures the roller you buy in December is identical to the one you bought in June.

Here is a comparison of how these new processes address common buyer pain points:

| Your Pain Point | Traditional Process | Future Process (5-Year Outlook) |

|---|---|---|

| Inconsistent Quality | Manual spot-checking; visual inspection. | Automated QC: 100% ultrasonic & magnetic scanning on the line. |

| Long Lead Time (Custom) | Manual mold making; long physical test cycles. | Additive Mfg: Rapid prototyping; fast Digital Twin testing. |

| Premature Wear | Standard heat-treated 40Mn steel. | Advanced Alloys: Boron steel, thermal spray coatings. |

How are they preparing for the rise of electric and autonomous construction machinery?

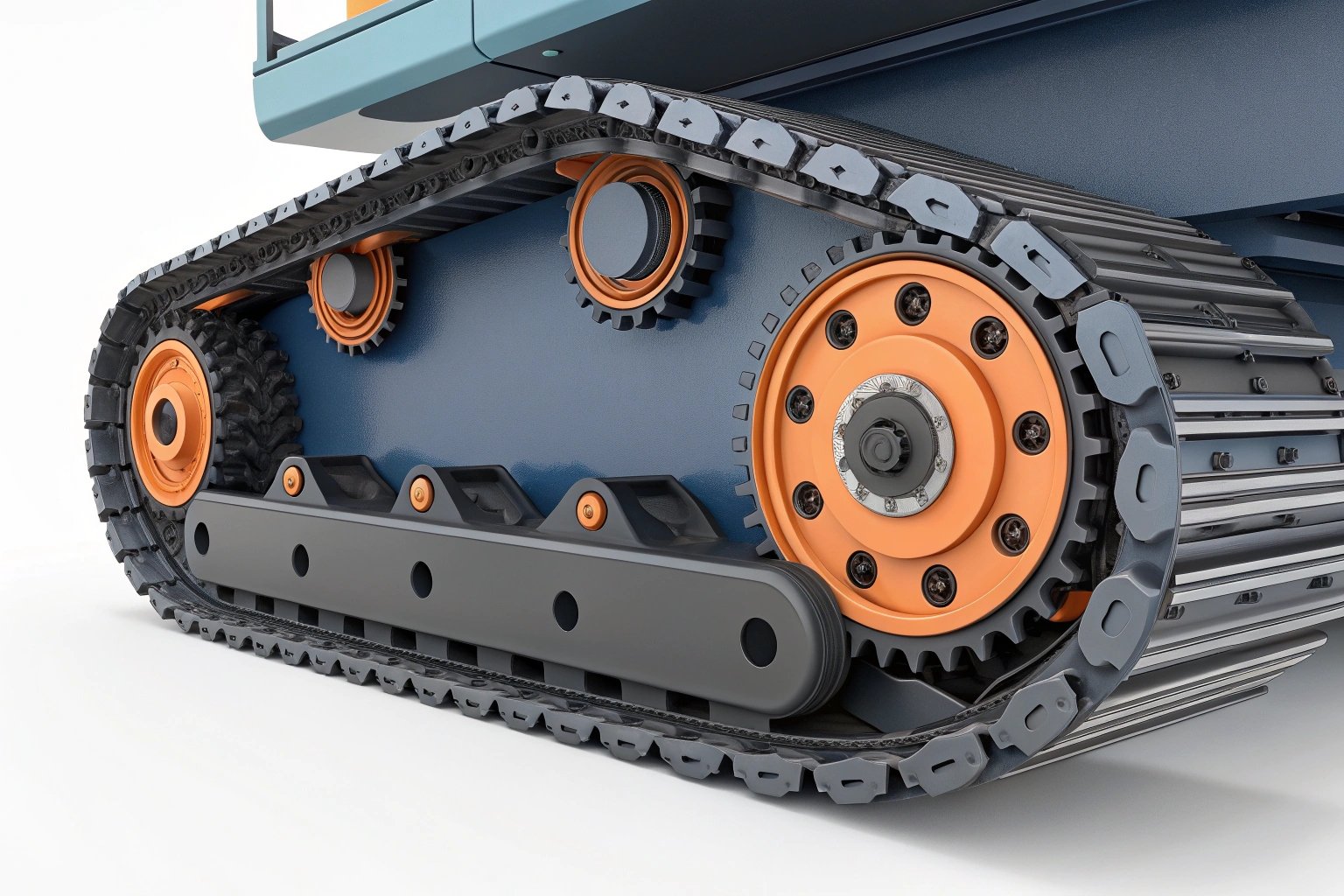

Electric excavators are coming to more job sites. Will your current parts work, or will they fail under the new stresses? We are re-engineering our components specifically for this shift.

Manufacturers are preparing for electric and autonomous machinery by developing energy-efficient, lightweight undercarriage components 8 to extend battery life. This includes using new materials, optimizing roller and idler designs to reduce friction, and integrating sensors for autonomous system feedback.

I often get asked this by forward-thinking clients. "Linda," they say, "I'm starting to see electric excavators. Does this change the undercarriage?" The answer is yes, absolutely.

An electric machine (EV) and a diesel machine deliver power differently. Electric motors provide instant torque. This puts a different, immediate stress on the drivetrain—specifically the sprocket and track chain. Autonomous machines are also different. They often run longer, more consistent shifts than human operators, which can accelerate wear if the parts are not designed for it.

Our preparation at Dingtai focuses on two key areas: efficiency and data.

1. Efficiency and Weight (For Electric)

In a diesel machine, a heavy undercarriage adds stability. In an electric machine, every extra pound of weight is a drain on the battery. The single biggest goal for electric machinery is "range," or how long it can run on a single charge.

- Reducing "Parasitic Load": The undercarriage is a major "parasitic load." This simply means it takes energy just to move the tracks. We are focused on R&D to reduce this drag. This involves new bearing and seal designs in our track rollers and carrier rollers that significantly reduce friction.

- Lightweighting: This connects back to our first point on materials. We are testing designs that use high-strength alloys to maintain durability while using less material. This makes the part lighter. A lighter track chain or roller frame means the battery can last longer, and the machine can do more work.

2. Data and Sensors (For Autonomous)

An autonomous excavator doesn't have a human operator who can "feel" if something is wrong. It relies on data. If an autonomous machine runs for 18 hours straight with a failing roller, it can cause a catastrophic failure that destroys the idler and track chain.

This is where the "Internet of Things" (IoT) comes in. We are developing "smart" components.

- Embedded Sensors: We are in the R&D phase for track rollers and idlers that have small sensors inside them. These sensors can monitor temperature, vibration, and rotation speed in real time.

- Predictive Maintenance: This sensor data feeds back to the machine's main computer. If a roller's temperature starts to climb, the autonomous system knows it's failing before it seizes. It can stop, flag the part for maintenance, and prevent a bigger failure. For a distributor like you, this means you can sell a "smart" part that saves your customer thousands in downtime.

What investments are they making in R&D to stay competitive?

Are you worried you are partnering with a "dinosaur" supplier? Suppliers who do not invest in R&D will eventually fail. We invest heavily in technology to guarantee your supply chain and product quality.

Leading manufacturers are making significant R&D investments in Digital Twin technology 9 for virtual stress-testing, AI-driven design optimization, and automated manufacturing lines for quality control. They are also collaborating with technology companies to integrate IoT and advanced analytics.

I know your frustration, David, when you talk to a supplier's salesperson who cannot answer basic technical questions. It is a clear sign that the company does not prioritize technology. At Dingtai, our 20+ technical engineers are the core of our business. Our R&D investment is how we stay competitive and ensure you get a reliable product.

Our investments are focused on predicting failure before it ever happens.

Using AI and Digital Twins in Design

This is the most exciting part of our R&D. In the past, to test a new track chain design, we had to physically make it. Then we had to put it on a test machine and run it for 1,000 hours. This is very slow and expensive.

Now, we use "Digital Twin" technology.

1. We build a perfect 3D computer model of the undercarriage part.

2. We also model the physical forces: the weight of the machine, the impact of hitting a rock, the abrasion of sand, and the tension of the track.

3. Our engineers can then run the part for a "virtual" 5,000 hours in just a few minutes.

We can see exactly where the stress points are. AI helps us optimize this. We can ask the computer, "Redesign this idler to be 10% lighter but maintain the same strength." The AI will run thousands of variations to find the best possible shape. This means the parts you receive from us have already been virtually tested for thousands of hours before the first piece of steel is ever cut.

Investment in Sustainable Manufacturing

R&D is not just about the part; it is about the process. Environmental regulations are getting stricter globally. We are investing in R&D for:

- Recycling: Developing better methods to recycle and repurpose materials from old parts.

- Energy Efficiency: Optimizing our heat-treatment furnaces and manufacturing lines to use less energy. This lowers our costs, which helps us provide you with a stable price. It also meets global environmental standards.

This table shows our key R&D focus areas:

| R&D Investment Area | Goal | Benefit for You (The Buyer) |

|---|---|---|

| Digital Twin Simulation | Virtually test parts under extreme stress. | Higher reliability; faster design of custom parts. |

| AI-Driven Design | Optimize part geometry for weight and strength. | Lighter, more efficient parts (better for EVs). |

| Automated QC Systems | 100% inspection of components on the line. | Zero-defect consistency between your orders. |

| Sustainable Processes | Reduce energy use; improve recycling. | Stable pricing; meets global environmental standards. |

Does their vision for the future align with my own business strategy?

A cheap supplier can hurt your brand. You need a long-term partner, not just a vendor. My vision is to align Dingtai's quality with your reputation, so you win more business.

A manufacturer's vision aligns with a distributor's strategy if the supplier focuses on long-term reliability, R&D investment, and quality consistency. This alignment builds brand reputation, reduces warranty claims, and ensures a stable supply chain for future machinery.

This is the most important question for you as a purchasing director. Your business profits by distributing high-quality aftermarket parts. Your reputation depends on the parts not failing. My business at Dingtai succeeds only if partners like you are successful.

Your main pain points, as I understand them, are:

1. Inconsistent product quality

2. Unexpected delivery delays

3. Poor technical support

4. Slow warranty response

Our vision for the future is built specifically to solve these four problems.

Alignment on Quality and Technology

Your strategy requires a top-tier product. My vision is to be that top-tier manufacturer. When we invest in AI-driven design and automated QC (as I mentioned), this is not just a "feature." This is a direct solution to your "inconsistent quality" pain point. We are moving from "inspecting quality in" to "building quality in" at every single step. We are an ISO9001 10 and SGS-certified factory, and our vision is to use technology to exceed those standards.

Alignment on Partnership and Support

You are a technical expert. You hate talking to salespeople who do not understand the product. My vision is a partnership, not a transaction. Our sales team includes our engineers. When you have a technical question about material composition or heat treatment, you talk directly to the people who design the part.

When you have a warranty claim (it happens, even to the best), our process is not to argue. Our process is to get the data (from the IoT sensor, perhaps), analyze the failure in our lab, and solve the problem. Our investment in R&D means we can analyze failures properly and prevent them from happening again.

Let's look at the alignment:

| Your Business Strategy | Our Vision (Dingtai) | How We Align |

|---|---|---|

| Build your brand on reliability. | Use R&D to create zero-defect parts. | Our tech (Digital Twin, QC) directly supports your brand promise. |

| Need stable inventory. | Invest in automated, efficient manufacturing. | Better production planning means reliable delivery schedules for you. |

| Require technical support. | Integrate engineers with sales and support. | You get fast, accurate answers, not a sales pitch. |

| Need long-term partners. | Focus on tech (IoT, EV) for the future. | We are growing with the market, ensuring you have parts for tomorrow's machines. |

My goal is to make your job easier. I want you to be so confident in Dingtai parts that you never have to worry about a customer complaint. That is our vision.

Conclusion

The next five years are about smart, durable, and efficient parts. As your manufacturing partner, my team at Dingtai is already building that future, ensuring your inventory is ready.

Footnotes

1. Overview of advanced materials enhancing construction equipment durability. ↩︎

2. How IoT sensors are used in heavy machinery for predictive maintenance. ↩︎

3. Engineering principles behind energy-efficient heavy equipment design. ↩︎

4. Properties and applications of HSLA steels in manufacturing. ↩︎

5. Benefits of using advanced composite materials for weight reduction. ↩︎

6. The role of 3D printing in manufacturing prototypes and parts. ↩︎

7. Guide to automated quality control systems in modern factories. ↩︎

8. How lightweight components improve electric vehicle battery life. ↩︎

9. Explanation of Digital Twin technology and its use in virtual testing. ↩︎

10. What an ISO 9001 certification means for quality management systems. ↩︎