Leading paragraph:

Are you a regular buyer of undercarriage parts like me, curious about the unique treatments pins and bushings undergo in track chains 1? This post sheds light on what goes into maximizing the durability and performance of these essential components.

Featured paragraph:

Pins and bushings in quality track chains receive elaborate and dedicated heat treatments along with specific alloy selections. Pins are often through-hardened or induction-hardened and tempered, while bushings undergo high-temperature carburizing and hardening processes. These steps ensure a robust surface that tackles wear, impact, and fatigue, aiming to enhance the pin-bushing joint’s longevity equivalent to or surpassing the links themselves.

Transition paragraph:

Continually improving component reliability is vital in the heavy machinery sector 2. The fine-tuned heat treatments employed help in achieving improved wear resistance 3 and impact durability, crucial for effective performance and maintenance over time.

Are the Pins and Bushings Induction Hardened?

Leading paragraph:

The superlative strength and toughness of track chain pins could have you wondering if induction-hardening 4 plays a part. Let's explore how it enhances overall durability.

Featured paragraph:

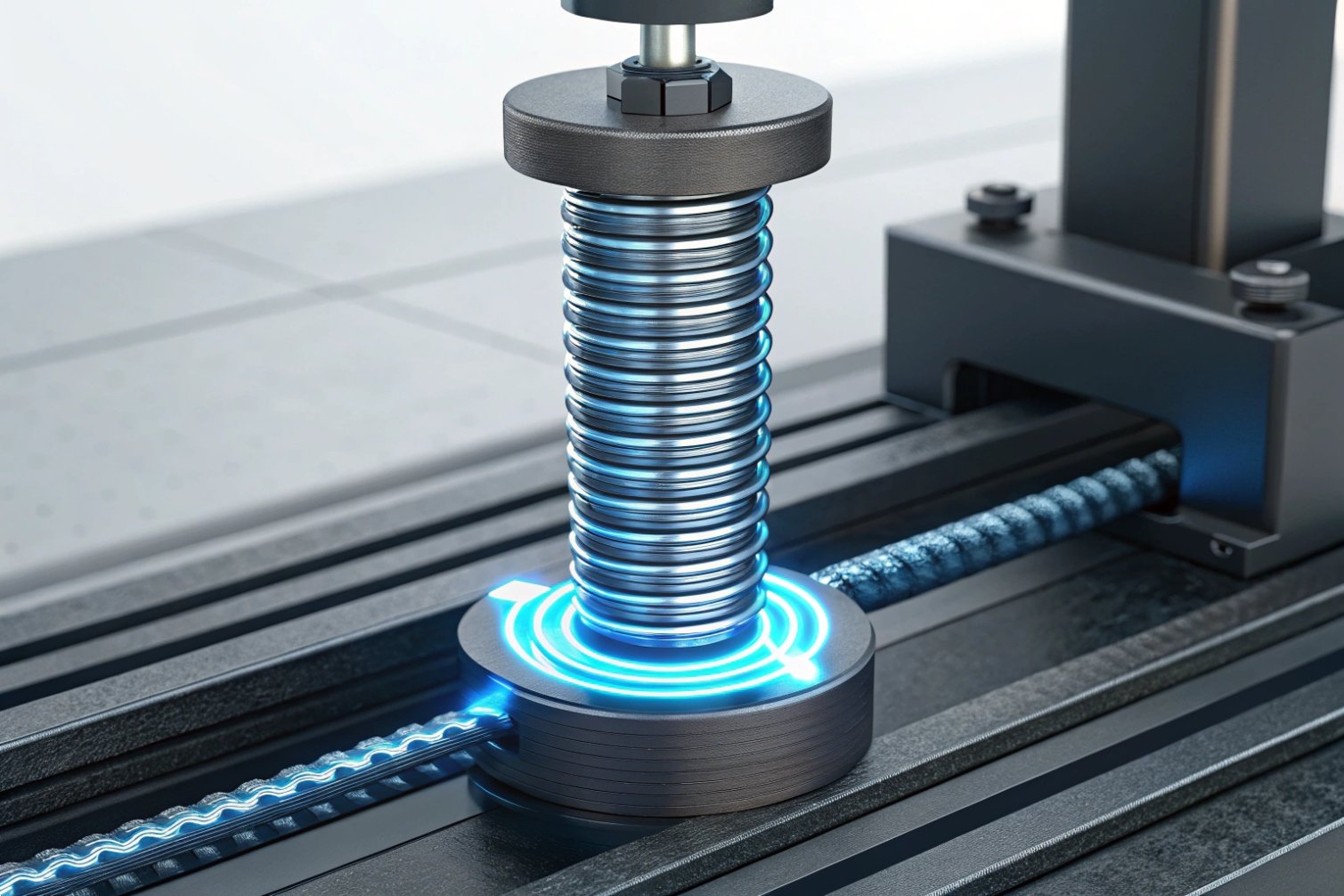

A central feature of pin treatment is the induction hardening process on surfaces and end areas. This creates hardness levels often around the mid-50s HRC, significant for resisting the wear and fatigue imposed by the high contact pressures 5 within operation settings.

Dive deeper paragraph:

Choosing medium or low-alloy medium-carbon steels 6 as the primary material, subsequently quenched and tempered, lays a sturdy foundation. This combination produces tough cores with optimal surface hardness, crucial in maintaining the component's integrity under stressful conditions.

Induction Hardening Process Parameters

| Property | Value |

|---|---|

| Main Material Type | Medium-carbon steels |

| Typical Surface Hardness | Mid-50s HRC |

| Core Toughness Feature | Quenched and Tempered |

This hardening is pivotal for SALT (sealed and lubricated) chains 7, where pins receive additional treatments like center and cross-drilling. Such designs foster internal oil reservoirs and passages, optimizing press-fit and oil retention.

What is the Surface Hardness and Case Depth for These Components?

Leading paragraph:

Understanding bushing properties is essential. Their hardened surfaces withstand immense operational stress, facilitated by meticulous heat treatment processes.

Featured paragraph:

Bushings undergo carburizing in specialized furnaces 8 at high temperatures, letting carbon infuse into the exterior layers. This results in a surface with profound hardness, often achieving mid-50s HRC or higher. The structural integrity derives from maintaining a tougher core capable of enduring impacts and bending loads.

Dive deeper paragraph:

Carburizing furnaces operate at high temperatures to allow carbon diffusion, which not only hardens the outer surface but also forms a ductile inner core. This dual-layer structure supports the bushings under various stresses, ensuring longevity and consistent performance.

Bushing Surface and Core Properties

| Treatment Type | Impact on Properties |

|---|---|

| Carburizing | Hard outer case |

| Surface Hardness Range | Mid-50s HRC or above |

| Core Toughness | Resilient and ductile |

Advanced models may even have equally innovative designs, like increased carburizing depth or alloy modifications 9, tailored for high-abrasion applications. This ensures extended lifespan amidst strenuous conditions.

How Do You Ensure the Core Toughness of the Pins?

Leading paragraph:

Achieving core toughness in pins requires a strategic heat treatment overlay to ensure lasting strength and reliability.

Featured paragraph:

Pin toughness is assured through selection of medium-carbon steels, followed by quenching and tempering protocols 10. This process alleviates internal stress, allowing for toughness improvement without compromising the exterior hardness gained from earlier treatments.

Dive deeper paragraph:

Pin core toughness is crucial in resisting impacts and improving fatigue life. The strategic combination of quenching and tempering balances hardness with ductility, making these components robust against continuous operational challenges.

Pin Core and Surface Enhancement

| Element | Description |

|---|---|

| Pin Material | Medium or low-alloy steel |

| Hardness Achievements | Through induction hardening |

| Stress Management | Quenching and Tempering |

Through precise engineering, these processes afford predictable performance characteristics and sustained durability—integral for handling heavy loads.

Is There a Specific Anti-Wear Coating or Finish Applied?

Leading paragraph:

Anti-wear coatings play a significant role in extending the life of pins and bushings while enabling seamless operation.

Featured paragraph:

Such surface finishes involve high polish processes post-treatment, which facilitate reduced friction and improved lubrication. Furthermore, pin and bushing dimensional matching provides ideal track joint reliability, ensuring optimal performance during operation.

Dive deeper paragraph:

Finishing processes like polishing reduce operational friction and improve the lubrication system's efficiency. This meticulous attention to the final coating assures prolonged component utility and minimizes wear-induced degradation.

Coating and Finish Details

| Coating Type | Purpose |

|---|---|

| High Polish | Improving lubrication |

| Dimensional Matching | Track joint reliability |

| Lubrication Features | Oil/Grease Systems usage |

Such finesse in design allows machinery specialists to rely confidently on the durability and service life of pins and bushings.

Conclusion

Distinct heat treatments and strategic alloy material selections play key roles in augmenting undercarriage component integrity. Pin and bushing strategies fortify core toughness and leverage protective surface treatments, enhancing wear resistance and durability.

Footnotes

1. Explanation of the function and common types of track chains in earthmoving equipment. ↩︎

2. Insights into the key operational and maintenance challenges faced by the heavy machinery industry. ↩︎

3. Detailed technical definition and methods for achieving high wear resistance in metal components. ↩︎

4. Guide to the principles and applications of induction hardening for enhancing material strength. ↩︎

5. Technical analysis of the stresses and high contact pressures found in track chain joints. ↩︎

6. Comprehensive properties, uses, and heat treatment responses of medium-carbon steel alloys. ↩︎

7. Learn about the design and maintenance benefits of sealed and lubricated (SALT) track chains. ↩︎

8. Detailed information on the high-temperature carburizing process used to case-harden steel parts. ↩︎

9. Explore how specific alloy elements modify and enhance the physical properties of steel components. ↩︎

10. Explanation of the combined process of quenching and tempering to balance hardness and ductility in steel. ↩︎