For safe sea transport 1 of heavy excavator undercarriage parts 2, robust packaging 3 is crucial to avoid damage, rust, and logistical issues 4.

Selecting the right packaging ensures your parts reach their destination securely and intact, preventing costly repairs or replacements.

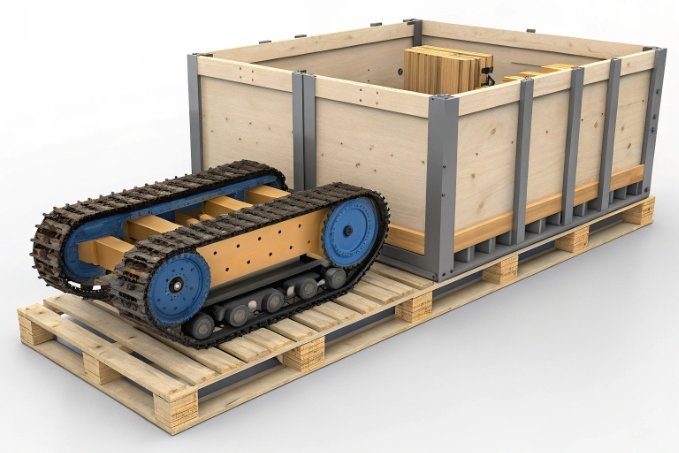

Should my parts be packed in strong, fumigated wooden crates or on steel pallets?

Choosing the right base for stability.

Yes, invest in fumigated wooden crates or steel pallets. Wooden crates offer durability and compliance with international regulations, while steel pallets add strength and are great for stacking and handling.

Packaging base options

- Fumigated Wood: Compliance and structural strength 5.

- Steel Pallets: Load-bearing capacity 6 and stability.

Packaging base comparison

| Material | Benefits | Suitability |

|---|---|---|

| Wooden Crates | Regulatory Compliance | Structural Support |

| Steel Pallets | High Strength | Stackability |

How can the parts be secured within the packaging to prevent movement and collision?

Ensuring stability and security.

Secure parts with foam inserts, rubber mats, and metal bands inside crates to minimize movement and prevent collision during shipping.

Internal security measures

- Foam Inserts: Shock absorption 7.

- Rubber Mats: Movement restriction.

- Metal Bands: Tight hold.

Securing strategies

| Method | Purpose | Protection |

|---|---|---|

| Foam Inserts | Absorb Impact | Shock Protection |

| Metal Bands | Tight Securing | Collision Prevention |

Should I ask for anti-rust protection for the machined surfaces?

Preventing corrosion in transit.

Indeed, request anti-rust protection such as VCI films or corrosion inhibitors for machined surfaces to prevent exposure and rust during sea freight.

Corrosion prevention

- VCI Films: Protect against salt exposure 8.

- Inhibitors: Prevent metal oxidation 9.

Rust prevention techniques

| Protection | Application | Benefit |

|---|---|---|

| VCI Films | Coverage | Corrosion Resistance |

| Inhibitors | Liquid Treatment | Anti-Rust Assurance |

Can the supplier provide photos of their standard export packaging for my review?

Visual verification for quality assurance.

Yes, request photos of standard export packaging to ensure it meets your specifications for protection, ease of handling, and compliance with transportation standards.

Packaging review process

- Visual Inspection: Confirm quality standards 10.

- Specification Check: Verify adherence to requirements.

Photo evaluation

| Evaluation | Purpose | Confirmation |

|---|---|---|

| Visual Photos | Quality Assurance | Meets Standards |

| Specification Review | Compliance | Requirement Fulfillment |

Conclusion

Requesting proper packaging with anti-rust protection and secure handling methods ensures that heavy undercarriage parts for excavators remain intact and corrosion-free during sea freight.

Footnotes

1. Guide to international maritime freight regulations and best practices. ↩︎

2. Examples of heavy-duty components like track chains and rollers. ↩︎

3. Learn about industrial packaging standards for heavy equipment. ↩︎

4. Common challenges in global supply chain and freight management. ↩︎

5. Info on ISPM 15 standards for wood fumigation in shipping. ↩︎

6. Technical specifications for steel pallet load-bearing capabilities. ↩︎

7. How foam inserts protect sensitive machinery during transit. ↩︎

8. Explanation of how Volatile Corrosion Inhibitor (VCI) films work. ↩︎

9. The science behind corrosion inhibitors for metal surfaces. ↩︎

10. Using visual inspection checklists for export packaging assurance. ↩︎