I know the frustration of seeing a machine sit idle because a single roller failed. It stops your project and eats your profits faster than anything else in this business.

An Ultimate Guide to Excavator Undercarriage Solutions covers core components, maintenance practices, and procurement strategies. It helps you optimize uptime and lifecycle costs by focusing on track chains, rollers, idlers, and sprockets for various terrains.

You have worked hard to build your reputation, and I want to help you protect it. Let’s look at how the right parts and plans keep your fleet moving and your costs down.

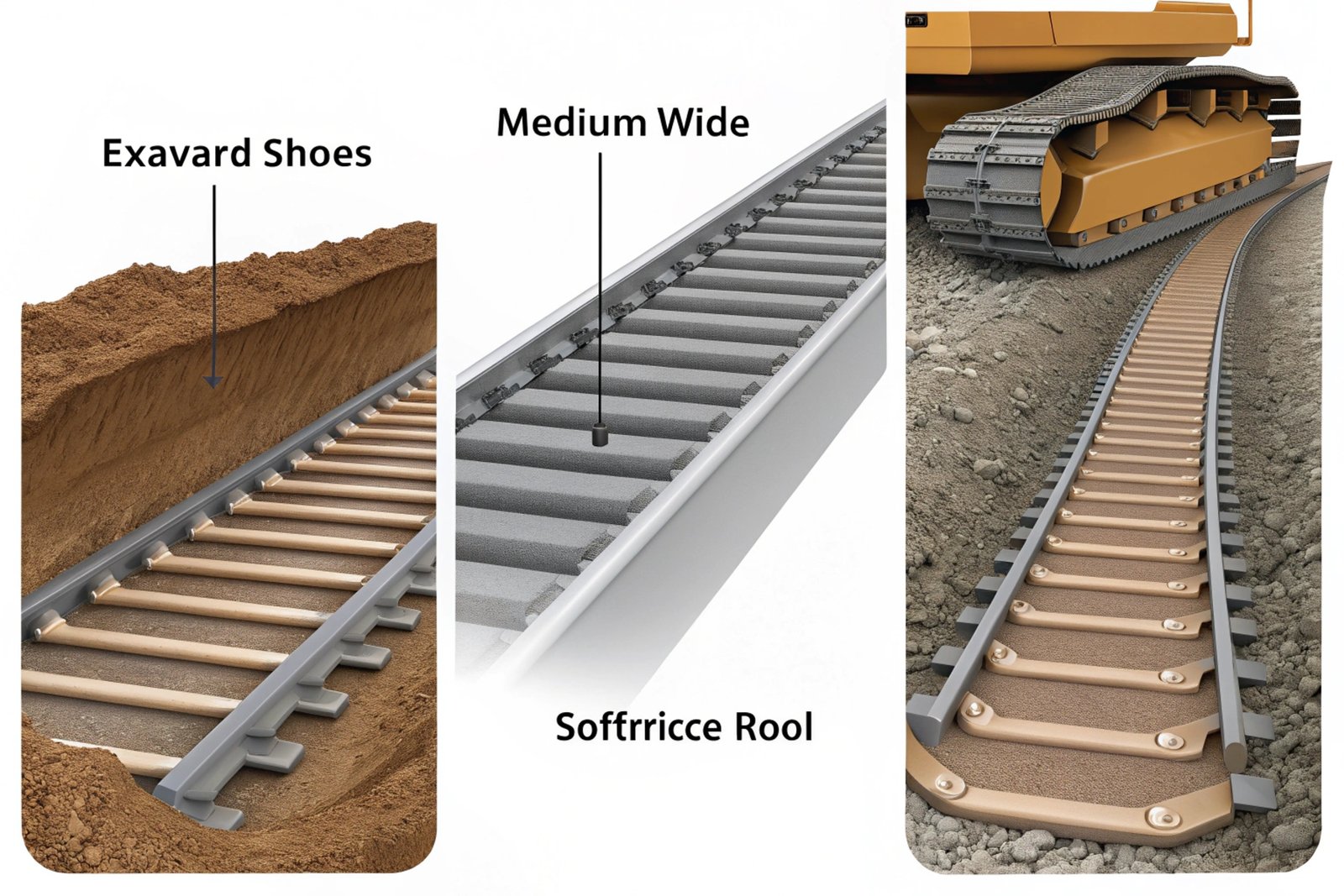

How can I optimize my fleet’s performance by choosing the right track shoe width for my terrain?

I once saw a client use wide swamp shoes on a rocky site, and they snapped within a week. I learned then that matching the shoe to the ground is the first step to saving money.

To optimize performance, you must choose the narrowest shoe possible that still provides enough flotation for your terrain. This reduces stress on the track links and bushings, significantly extending the overall life of your undercarriage components.

Understanding the Trade-off Between Flotation and Stress

When I talk to fleet managers, I always explain that wider is not always better. It is a common mistake. If you work in soft mud or swampy areas, you need wide shoes to stay on top. However, if you take those same wide shoes onto hard, rocky ground, the outer edges of the shoes carry too much weight. This creates a "bridge" effect. This force bends the shoes and puts massive pressure on the pins and bushings 1 in your track chain.

Impact of Terrain on Shoe Selection

I have categorized the common terrain types I see in the field. Using the wrong shoe type can cut your undercarriage life by 50%. You need to think about the "ground pressure" 2 vs. the "mechanical stress" on the metal.

Recommended Shoe Widths by Application

| Terrain Type | Recommended Shoe Width | Primary Benefit | Potential Risk of Wrong Choice |

|---|---|---|---|

| Hard Rock / Demo | Narrow (Standard) | High durability, low bending | Sinking in soft soil |

| General Dirt | Medium | Good balance of grip and life | Moderate wear in rocks |

| Soft Mud / Swamp | Wide (LGP) | High flotation, stays on top | Easy bending on hard spots |

Why Narrower is Often Safer

I always tell my customers: "Go as narrow as you can." Narrow shoes keep the load centered over the track rollers. This prevents the "twisting" motion that ruins track links 3. If you use a shoe that is 100mm wider than necessary, you are essentially giving the ground a longer lever to pry your undercarriage apart. I have seen this lead to cracked track frames and leaking rollers.

The Role of Grousers

We also need to look at the number of grousers (the ribs on the shoe). Single grousers are for dozers that need to dig deep for traction. Triple grousers 4 are for excavators because they offer better maneuverability and don't tear up the ground as much. If your operator is doing a lot of turning on hard surfaces, those triple grousers will save your drive motor from extra strain.

What are the cost-benefit advantages of sourcing directly from a Chinese OEM manufacturer like Dingtai?

I used to hear people worry about "buying from China," but after 20 years in this factory, I have seen our quality beat the big brands. I take pride in every roller we ship.

Sourcing from a Chinese OEM like Dingtai provides a 30-50% cost saving without sacrificing quality. You get direct access to technical support, 100% quality inspection, and the ability to customize parts for specific high-wear environments.

Eliminating the Middleman Markup

When you buy from a local dealer in the US or Europe, you are paying for their rent, their staff, and their profit margin. By coming to me directly at Dingtai, you cut those costs out. We are the factory. We buy the raw steel, we do the heat treatment 5, and we assemble the parts. You are paying for the steel and the labor, not the fancy showroom. This allows you to put that saved money back into your business or buy more inventory.

Quality Control and Certification

I know David Miller cares about consistency. That is why we follow ISO 9001 6 standards strictly. Many people think "direct" means "unregulated," but it is the opposite. At our facility in Fujian, we perform 100% inspections. We check the hardness of every batch of rollers. If the heat treatment is even one degree off, we don't ship it.

Comparison: Direct OEM vs. Local Retailer

| Feature | Dingtai Direct (OEM) | Local Retailer |

|---|---|---|

| Price | Factory Direct (Lower) | Retail Markup (Higher) |

| Customization | Available (Material/Design) | None (Off-the-shelf) |

| Technical Support | Direct from Engineers | Sales Staff only |

| Traceability | Full Material Reports | Often Limited |

Technical Transparency

I find that many sales reps at big dealerships don't actually know how a roller is made. They just know the part number. When you talk to us, you are talking to the people who design the seals and choose the oil. If you have a specific problem, like high-abrasion 7 sand in a desert mine, I can change the manganese content in our steel or suggest a different heat treatment depth. You don't get that kind of expert help from a catalog.

Building a Strategic Partnership

I don't just want to sell you one container of track chains. I want to be your partner for the next ten years. Direct sourcing allows us to build a relationship where I understand your inventory needs. We can sync our production with your peak seasons. This transparency prevents the "out of stock" nightmares that David Miller hates. We provide transparent tracking, so you know exactly when your parts will hit the port.

How do I develop a proactive maintenance schedule to minimize my equipment downtime?

I have seen grown men cry when a $100,000 excavator breaks down because of a $500 idler. I tell them that a simple daily check would have saved the whole week.

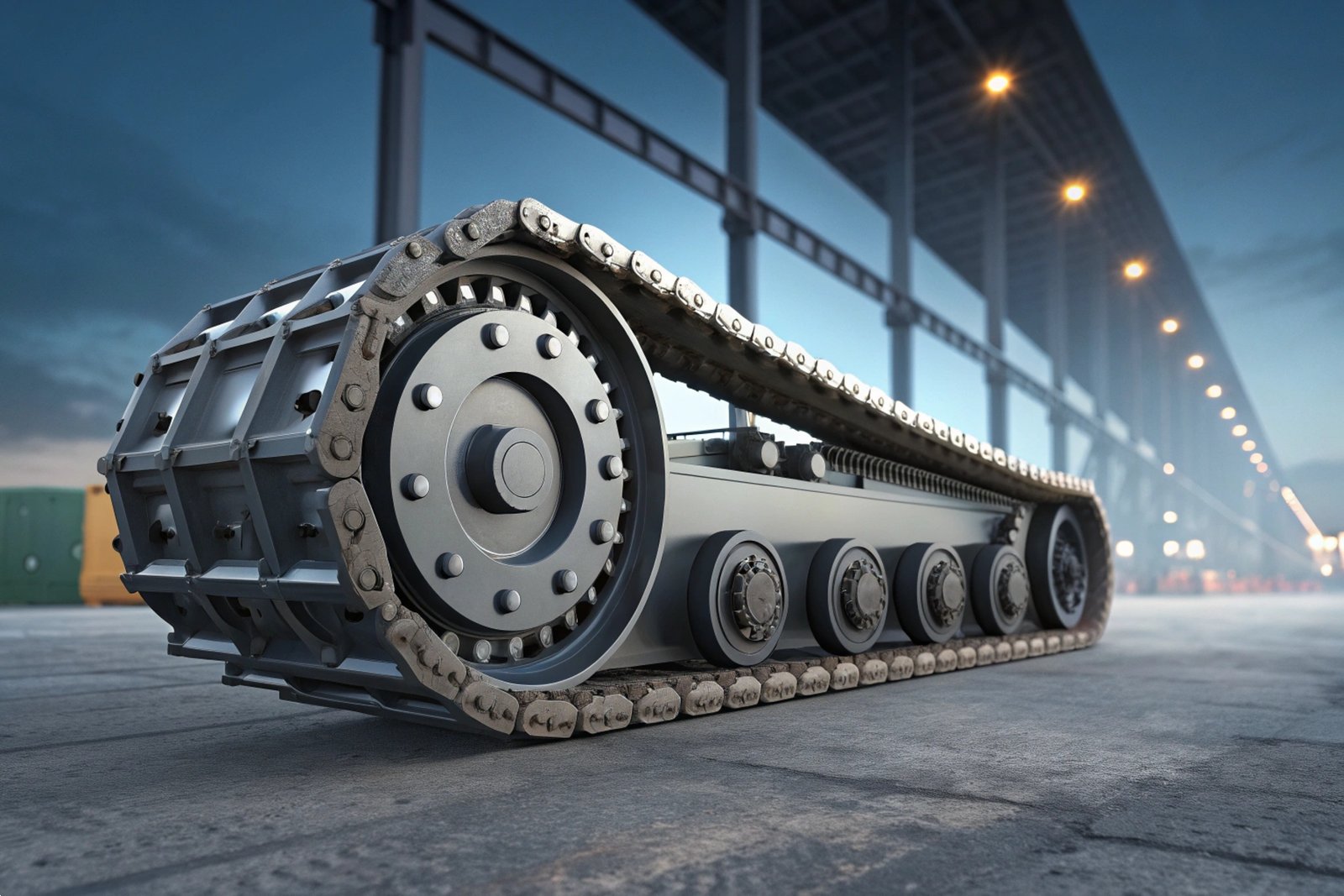

A proactive schedule involves daily cleaning, weekly tension checks, and 500-hour professional inspections. By tracking wear trends and rotating rollers, you can extend the life of your undercarriage by thousands of hours and avoid emergency repairs.

The Power of the Daily Walkaround

I always tell my clients to give their operators a shovel. It sounds simple, but packing mud around the rollers is the "silent killer." When mud dries, it acts like sandpaper against the seals. If those seals fail, the oil leaks out, and the roller seizes. A five-minute cleaning at the end of the day is the cheapest insurance policy you can buy. I have seen machines last 30% longer just because the operator kept the tracks clean.

Mastering Track Tension

Tension is the most misunderstood part of maintenance. If it is too tight, you wear out the bushings and sprockets. If it is too loose, you risk throwing a track. I recommend checking track tension 8 every week or whenever you change job sites. If the soil is soft and muddy, you need the tracks a bit looser so the mud can squeeze out. If it is rocky, keep them at the manufacturer's spec.

Maintenance Intervals for Undercarriage Parts

| Task | Frequency | Focus Area |

|---|---|---|

| Cleaning | Daily | Remove mud, rocks, and debris |

| Tension Check | Weekly | Adjust based on soil conditions |

| Oil Leak Check | Every 250 Hours | Check rollers and idlers for wet spots |

| Wear Measurement | Every 500-1000 Hours | Use calipers or ultrasonic tools |

Rotating Your Rollers

Just like the tires on your truck, your track rollers wear unevenly. The rollers in the center usually carry more load than the ones at the ends. I suggest rotating them every 1,000 hours. Moving the center rollers to the ends and vice versa balances the wear. This simple trick can get you an extra six months of life out of a set of rollers. Most people don't do this because it takes effort, but the savings are massive.

Using Technology to Track Wear

I highly recommend using ultrasonic wear kits 9. We use them at the factory to test our parts, and you should use them in the field. By measuring the thickness of the metal on the rollers and links, you can predict exactly when they will fail. This allows you to order parts from me a month in advance. You can schedule the repair for a weekend when the machine isn't needed, instead of waiting for a breakdown in the middle of a big job.

What technical innovations in seal design should I look for to enhance my undercarriage reliability?

I remember the old days when seals leaked every few hundred hours. I spent years in our R&D lab testing new rubbers just to make sure our customers never had that problem again.

Look for heavy-duty "dual-cone" or "mirror" seals made from high-nitrile rubber. These innovations prevent oil leaks and keep contaminants out, which is essential for the "lubricated for life" performance required in modern, high-intensity construction and mining sites.

The Importance of the Mirror Seal

When I explain seals to David, I focus on the "mirror" finish. These seals consist of two metal rings that rub against each other. They are polished so smoothly that they look like mirrors. This precision fit is what keeps the oil inside the roller. If the polish is even slightly rough, the seal will fail under heat. At Dingtai, we use specialized grinding machines to ensure these surfaces are perfect. This tech is what allows our rollers to be "maintenance-free" 10.

Material Science: Nitrile and Silicone

The rubber "O-rings" behind the metal seals are just as important. In the past, these would get brittle in the cold or melt in the heat. We now use advanced nitrile compounds that stay flexible from -40°C to over 100°C. If you are working in a Canadian winter or a Middle Eastern summer, you need these specific materials. I always ask my customers about their climate so I can recommend the right seal compound.

Why Seal Technology Fails

Most seal failures I see come from "trash wrapping." This is when wire, nylon string, or vines wrap around the shaft and cut into the seal. I have worked with our engineers to design "stepped" housings that help deflect this debris. When you look at our rollers, you will see a specific lip design that guards the seal. It is a small detail, but it prevents the #1 cause of roller failure.

Comparing Old vs. New Seal Tech

Seal Technology Comparison

| Feature | Old Generation Seals | Modern Mirror Seals (Dingtai) |

|---|---|---|

| Sealing Surface | Simple Rubber Lip | Precision Lapped Metal Rings |

| Temperature Range | Limited (-10 to 60°C) | Extreme (-40 to 120°C) |

| Service Life | 1,000 - 1,500 Hours | 3,000 - 5,000+ Hours |

| Contaminant Defense | Low (Easily Punctured) | High (Mechanical Barrier) |

Lubrication Innovation

Reliability isn't just about the seal; it is about what is behind it. We now use synthetic oils that don't break down under high pressure. When combined with our mirror seals, the oil stays clean for the entire life of the part. I tell my clients that if they don't see oil on the outside of the roller, they shouldn't touch the inside. Modern seals are designed to stay closed. Opening them to "check the oil" usually just lets dirt in and ruins the seal.

Conclusion

Managing your undercarriage doesn't have to be a headache if you have the right parts and a solid plan. By choosing the right shoes, sourcing from a trusted OEM, and keeping a tight maintenance schedule, you will keep your machines running and your business growing.

Footnotes

1. Expert forum discussions on the wear and maintenance of track chain pins and bushings. ↩︎

2. Technical guide explaining the impact of ground pressure on construction equipment efficiency. ↩︎

3. Resource for understanding the structural integrity and replacement cycles of track links. ↩︎

4. Overview of different track shoe types and the benefits of triple grousers. ↩︎

5. Deep dive into the metallurgical processes of heat treatment for heavy machinery parts. ↩︎

6. Official standard for quality management systems ensuring consistent product excellence. ↩︎

7. Scientific insights into material wear and abrasion resistance in extreme environments. ↩︎

8. Best practices for adjusting and maintaining track tension for heavy excavators. ↩︎

9. Information on using ultrasonic tools to measure undercarriage wear without disassembly. ↩︎

10. Trends in construction equipment design moving toward maintenance-free components. ↩︎