I have spent over 20 years managing heavy machinery fleets, and I know the stress of a broken track in the middle of a deadline. Choosing the right parts is the only way to avoid that nightmare.

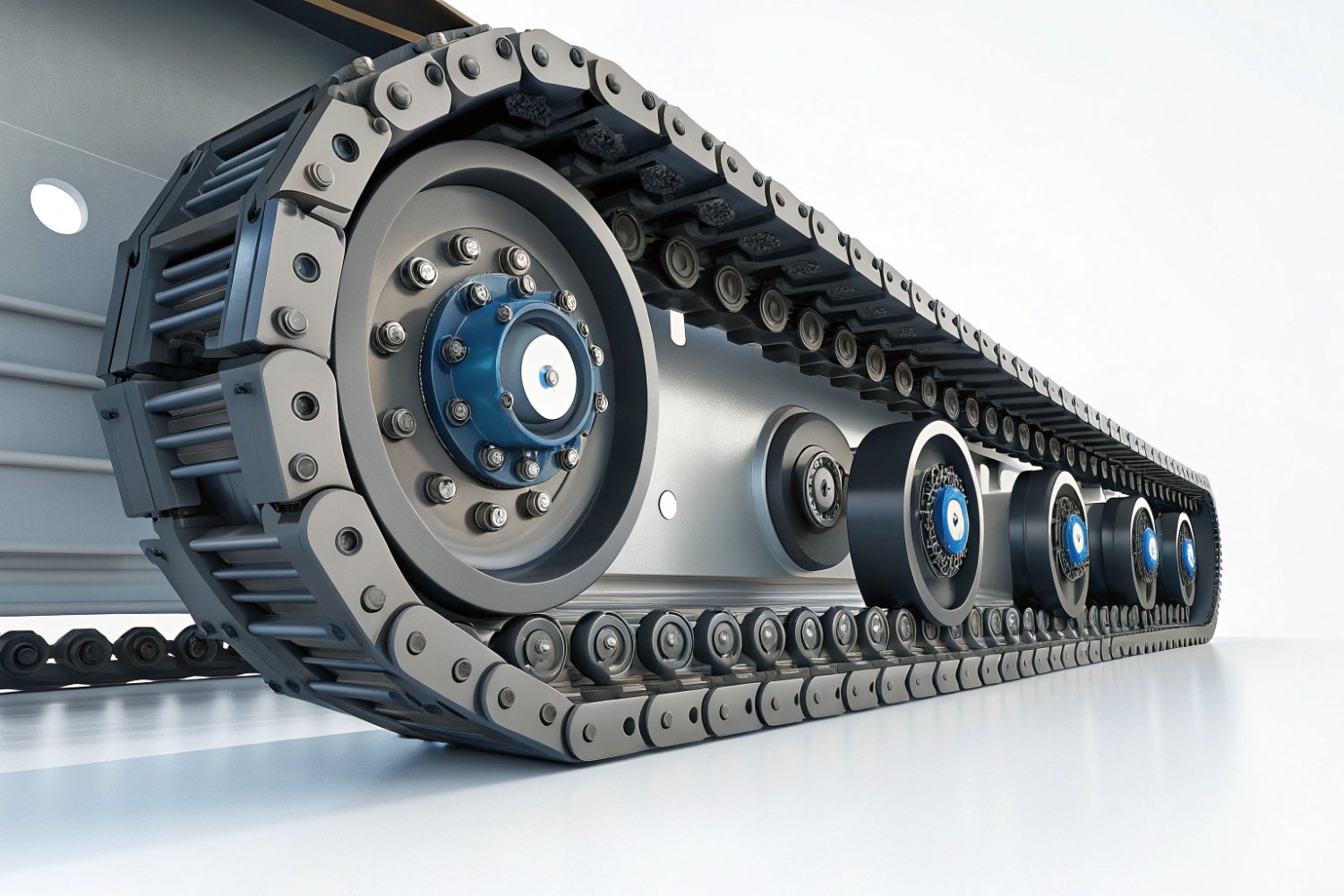

The top 7 Hitachi undercarriage parts for optimal performance include track chains, track shoes, idlers, track rollers, sprockets, carrier rollers, and tensioning systems. Selecting high-quality, induction-hardened components ensures your machine maintains maximum traction, stability, and durability in harsh working environments.

Everything in a Hitachi undercarriage works together. If one part fails, it creates a domino effect that ruins the rest. It is vital to understand which parts take the most beating so you can keep your machine running smoothly and profitably.

How do my Hitachi-compatible track rollers handle heavy side-loading in rocky terrain?

I remember a client in a rocky quarry who kept breaking his rollers every month. We looked at his setup and realized he needed a specific internal bearing design to handle those sideways forces.

Hitachi-compatible track rollers 1 handle heavy side-loading through reinforced internal shafts and large-diameter flanges. These features distribute the weight across a wider surface area, while high-quality seals prevent rock dust from grinding down the internal bronze bushings or roller bearings.

The Mechanics of Side-Loading Resistance

In rocky terrain, your excavator does not just move forward and backward. It often twists or sits on uneven surfaces. This puts "side-load" on the track rollers. If a roller is cheaply made, the flange—the part that keeps the track chain 2 lined up—will chip or break off. When that happens, your track can slide right off the machine.

At Dingtai, we use deep induction hardening 3 on the roller shells. This means the outer layer is very hard to resist wear, but the inner core stays tough so it doesn't snap under pressure. We also focus on the "Dual Mirror Seals." These seals keep the oil inside the roller for its entire life. In a rocky environment, the dust is like sandpaper. If your seals fail, that dust gets inside and turns your lubrication into a grinding paste.

Understanding Roller Construction

To help you compare, I have put together a table showing what makes a roller "heavy-duty" versus a standard one.

| Feature | Standard Roller | Dingtai Heavy-Duty Roller |

|---|---|---|

| Material | 50Mn Steel | 40Mn2 or 50Mn with Boron |

| Hardening Depth | 3-5mm | 5-8mm |

| Seal Type | Standard Rubber | High-Quality Nitrile/Viton |

| Internal Bushing | Zinc Alloy | Bimetal Bronze |

Why Precision Fit Matters

When you are working with a Hitachi machine, the manufacturing tolerances 4 are tight. If a roller is even a few millimeters off in its dimensions, it won't sit correctly on the track link. This creates "point loading," where all the weight hits one tiny spot. Over time, this will crush the roller or stretch your track chain. Always check that your supplier provides a 100% quality check before the parts leave the factory.

Why are reinforced track guides essential for my Hitachi excavator's stability on slopes?

Whenever I see an excavator working on a steep hill, I look at the track guides. I once saw a machine lose its track on a 30-degree slope because the guides were worn out; it was a dangerous and expensive mistake.

Reinforced track guides are essential for stability because they prevent the track chain from jumping off the rollers when the machine is tilted. They act as a physical mechanical barrier 5 that keeps the links aligned, even when gravity is trying to pull the heavy chain assembly downward.

Safety and Stability on Slopes

Working on a slope puts a massive amount of lateral stress 6 on your undercarriage. Without strong guides, the track chain wants to sag and move away from the center of the rollers. If the chain moves too far, the sprocket will miss the bushings, and you will "throw a track." Putting a track back on while on a slope is not just hard work; it is extremely dangerous for the crew.

The Role of Material Strength

Most standard guides are just simple steel plates. However, reinforced versions use high-tensile steel and are often thicker at the points of contact. We design ours to withstand the "shoving" force of a 30-ton machine sliding slightly on loose soil.

Benefits of Full-Length vs. Segmented Guides

Depending on your Hitachi model, you might have the choice between short guides or full-length track guards.

- Full-Length Guards: These offer the best protection. They keep rocks out of the roller area and ensure the chain stays perfectly straight from the idler to the sprocket.

- Segmented Guides: These are easier to replace and cheaper, but they leave gaps where rocks can get stuck.

If you are working in mining or heavy construction, I always recommend the full-length option. It adds weight to the machine, which actually lowers the center of gravity 7 and makes it feel more "planted" on the ground.

Maintenance and Inspection

You should check your track guides for "shiny spots." If the inside of the guide is polished like a mirror, it means your track is rubbing against it too much. This could mean your tracks are too loose or your machine's frame is slightly bent. Catching this early saves your track links from wearing down on the sides.

How can high-quality recoil springs improve the overall vibration dampening of my Hitachi machine?

I have talked to many operators who complain about back pain after a long shift. Usually, the culprit is a seized recoil spring that has turned their excavator into a vibrating jackhammer.

High-quality recoil springs 8 improve vibration dampening by absorbing the sudden shocks caused by debris entering the tracks. A functional spring allows the front idler to move backward slightly, "swallowing" the shock instead of passing that energy through the frame to the operator's cab.

The Science of Shock Absorption

The recoil spring is a giant safety valve. When a rock gets caught between the sprocket and the chain, the tension spikes instantly. If the spring is high-quality and well-maintained, it compresses. This prevents the track chain from snapping. But beyond safety, it acts like a car's suspension system 9. Every time you drive over a hard bump, that spring takes the hit so the rest of the metal frame doesn't have to.

Material Quality and Longevity

Not all springs are equal. Cheap springs lose their "rate" (their stiffness) over time. This makes the track feel sloppy. At Dingtai, we use high-silicon manganese steel for our springs. We also perform a "load test" on every assembly. We want to make sure that even after 5,000 hours of work, the spring still has the same tension it had on day one.

Components of the Tensioner Group

The spring is only part of the story. You also have the grease cylinder and the seal kit.

| Component | Function | Maintenance Sign |

|---|---|---|

| Recoil Spring | Absorbs shock and maintains tension | Cracks or sagging coils |

| Grease Cylinder | Adjusts the track slack | Leaking grease around the nut |

| Y-Seal Kit | Keeps hydraulic pressure inside | Track loses tension quickly |

| Chrome Rod | Connects the idler to the spring | Pitting or rust on the surface |

Impact on Other Parts

When your recoil system works well, your idlers and rollers last longer. High vibration causes "fretting," where metal surfaces rub together and create fine dust. By dampening that vibration, you are literally extending the life of every undercarriage component 10 in the system. It is a small investment that protects a $50,000 undercarriage system.

What benefits do I get from using induction-hardened track pins in my Hitachi undercarriage?

I once had a customer who bought cheap track chains and was shocked when the tracks "stretched" after only 500 hours. I had to explain that the metal hadn't stretched; the pins had simply worn down because they weren't hardened correctly.

Induction-hardened track pins offer a "hard-shell, soft-core" structure that provides extreme wear resistance on the surface while maintaining the flexibility to handle impacts. This specific heat treatment prevents the track pitch from "extending," which is the primary cause of sprocket wear and track derailment.

The "Stretching" Myth

Many people think the steel in a track chain stretches like a rubber band. That is almost never true. What actually happens is the pins and bushings wear down where they touch each other. If a pin loses 1mm of thickness, and you have 50 pins in a chain, the track is now 50mm longer. This is called "pitch extension." Once this happens, the chain no longer fits the sprocket teeth perfectly.

Why Induction Hardening?

We use a process called induction hardening. We wrap the pin in an electrical coil that heats the surface to a glowing red in seconds, then we quench it in water or oil. This creates a surface that is as hard as a file. However, the center of the pin stays "annealed" or soft. This is critical. If the whole pin were hard, it would be brittle like glass and snap the first time you hit a rock.

Comparative Advantage of High-Quality Pins

When you buy from a professional manufacturer like Dingtai, you are getting pins that match the OEM specs of companies like Caterpillar or Komatsu. We ensure the hardness depth is consistent. If the hardening is too shallow, it wears through quickly. If it is too deep, the pin snaps.

Maintenance of Pins and Bushings

The best way to get the most out of these pins is to use "SALT" chains—Sealed and Lubricated Tracks. These chains have a reservoir of oil inside the pin.

| Feature | Standard Dry Chain | Sealed & Lubricated (SALT) |

|---|---|---|

| Internal Wear | High (metal on metal) | Low (oil film protection) |

| Noise Level | Loud squeaking | Quiet operation |

| Total Life | 2,000 - 3,000 Hours | 4,000 - 6,000 Hours |

| Best Use | Low-use / Budget | High-production / Heavy use |

By using hardened pins and keeping them lubricated, you reduce the cost per hour of your machine. For a big distributor like David Miller, this means fewer complaints from his customers and a much stronger reputation for his brand.

Conclusion

Choosing the right Hitachi undercarriage parts is about more than just finding a low price. It is about understanding how hardened pins, reinforced guides, and heavy-duty rollers work together to keep your machine stable and productive.

Footnotes

1. Explore official Hitachi undercarriage parts and their engineering specifications. ↩︎

2. Technical discussion on track chain wear patterns and maintenance strategies. ↩︎

3. Understanding the induction hardening process for industrial steel components. ↩︎

4. Reference for international standards on length and manufacturing precision. ↩︎

5. OSHA guidelines for mechanical barriers and safety guarding in heavy machinery. ↩︎

6. Scientific explanation of lateral stress and its impact on structural engineering. ↩︎

7. Physics principles behind center of gravity and its role in vehicle stability. ↩︎

8. Detailed overview of recoil spring assemblies for heavy crawler equipment. ↩︎

9. How suspension systems manage shock and vibration in mechanical vehicles. ↩︎

10. Best practices for maintaining excavator undercarriages to maximize service life. ↩︎