I know how it feels when a machine stops on a busy job site. It is frustrating to see your profit disappear because of a broken track or a worn-out roller.

Proper track tension, alignment, and track shoe selection are the top drivers of life, traction, and fuel efficiency. Regular inspections and proactive maintenance prevent cascading wear and costly downtime. Suiting the track to the terrain ensures the best balance of flotation, traction, and durability.

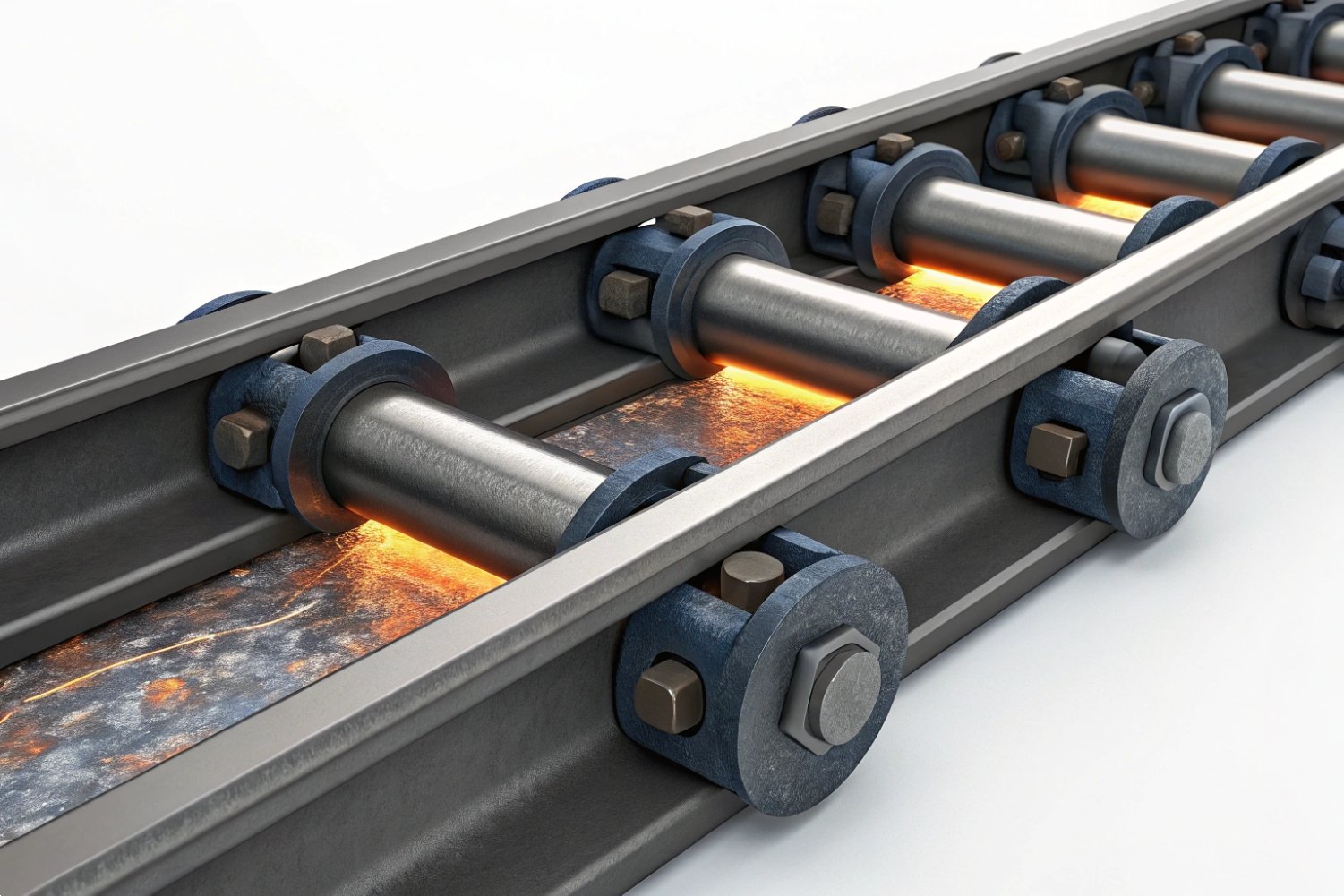

Keeping your heavy equipment moving requires more than just luck. It takes a deep understanding of how metal meets the ground. When I talk to my clients, I always tell them that the undercarriage is the heart of their machine's mobility. If you ignore it, you pay for it later. Let’s look at exactly what keeps your tracks running at their best.

How does the metallurgy of my track links affect the overall performance in rocky terrain?

I have seen many cheap track links snap like dry twigs when they hit hard rock. It breaks my heart to see a customer lose money because the metal was not right.

Track links made with high-quality boron steel and precise deep-heat treatment offer the best impact resistance. Proper metallurgy ensures the core remains tough while the surface stays hard. This prevents cracks and surface flaking even when the machine is working on sharp, abrasive rocks and hard ground.

The secret to a long-lasting track link is not just the type of steel. It is all about the heat treatment process. In my 20 years of experience at Dingtai, I have learned that "surface hardness" is only half the story. If the hardness does not go deep enough, the link will wear out very fast once the top layer is gone. We use specialized induction hardening 1 to ensure the wear depth is consistent. This is vital for David Miller and other pros who need their machines to last in tough US job sites.

Understanding Steel Grades and Hardness

When you buy parts, you should ask about the material. Most high-performance links use 35MnB or 40Mn2 2. These materials respond well to heat. If the steel is too soft, the links will stretch. If it is too brittle, they will crack under the weight of a 40-ton excavator. We balance these properties so the link can "flex" slightly without breaking.

| Feature | Low-Quality Link | Dingtai Professional Link |

|---|---|---|

| Material | Standard Carbon Steel | 35MnB Boron Steel |

| Hardness Depth | 3mm - 5mm | 8mm - 12mm (Model dependent) |

| Heat Treatment | Surface Only | Deep Induction Hardening |

| Impact Strength | Low (Prone to cracking) | High (Absorbs shock) |

Why Surface Geometry Matters

It is not just about the metal; it is about the shape. A well-designed track link has a rail surface that matches the rollers perfectly. If the geometry is off by even a millimeter, you get uneven wear 3. This "washes out" the pins and bushings much faster. Using professional-grade links ensures that the weight of the machine is spread evenly across the entire undercarriage. This reduces the pressure on single points and stops the metal from "mushrooming" or deforming under heavy loads.

What impact does the precision of my idler alignment have on my fuel efficiency and wear?

I once saw a machine burning through fuel like a jet engine just because the idler was crooked. It was fighting itself every step of the way, and the owner was confused.

Precise idler alignment reduces rolling resistance, which directly lowers fuel consumption and prevents side-loading wear. When the idler is straight, the track chain travels in a true path. This stops the chain from rubbing against the roller flanges and prevents premature wear on the link sides.

Alignment is a silent killer of undercarriage life. If your idler is off-center, the entire track starts to "snake." This creates friction. Friction creates heat. Heat destroys your seals and softens the metal. For a fleet manager 4, this means you are paying for extra fuel and replacing parts twice as often as you should. I always tell my team to check the shims behind the idler brackets. A few small metal plates can save you thousands of dollars in the long run.

The Connection Between Friction and Fuel

Think of your track as a giant bicycle chain. If the gears are not lined up, it is harder to pedal. For a bulldozer, the engine has to work harder to push that misaligned track. This can increase fuel burn 5 by as much as 5% to 10%. Over a year, that is a huge amount of money.

Symptoms of Misalignment

You can usually tell if your idler is misaligned by looking for these signs:

- Shiny edges on the inside of the track link rails.

- Uneven wear on one side of the idler flange.

- Heating up of the idler hub after only a short time of operation.

- Tracking to one side when the operator tries to drive in a straight line.

| Component | Result of Good Alignment | Result of Misalignment |

|---|---|---|

| Track Links | Even wear on rail surface | Heavy wear on side of links |

| Fuel Tank | Standard consumption | Increased fuel burn (5%+) |

| Roller Flanges | Minimal contact | Rapid thinning of flanges |

| Operator Comfort | Smooth ride | Vibration and noise |

How can I ensure my recoil springs are functioning correctly to absorb shocks during operation?

I have climbed under many machines where the recoil spring was so packed with dried mud it was basically a solid rock. That is a recipe for disaster.

Correct recoil spring function depends on keeping the area clean and ensuring the spring is not broken or bottomed out. You should check that the tensioner grease cylinder moves freely. A working spring protects the idler and track chain from high-impact shocks by allowing the idler to move back when hitting obstacles.

The recoil spring is like a big insurance policy for your undercarriage. When your excavator hits a big rock, the spring compresses to take the hit. If the spring is stuck or broken, that force goes straight into the pins, bushings, and the final drive 6. I have seen final drive housings crack because a $200 spring was neglected. At Dingtai, we manufacture our spring assemblies to handle extreme compression cycles. We make sure the tension is exactly what the OEM suggests 7 for brands like Cat or Komatsu.

Testing Your Recoil System

A simple way to check your recoil system is to watch the idler while the machine moves over a small bump. The idler should move slightly back and then return to its spot. If it doesn't move, or if it stays back, your spring or your adjuster cylinder is seized.

- Clean the Mud: Always wash out the "rock guards" and the spring area. Packed debris prevents the spring from moving.

- Check for Leaks: If the grease cylinder is leaking, you will lose track tension, and the spring won't be held in the right starting position.

- Inspect for Cracks: Look at the coils of the spring. If you see a crack, replace it immediately. A snapping spring under tension is extremely dangerous for nearby workers.

Why Quality Matters for Springs

Not all springs are equal. Some aftermarket springs lose their "push" after just a few months. This is called "taking a set." We use high-tensile spring steel 8 that is shot-peened to improve fatigue life. This ensures that the spring keeps the track at the right tension for years, not just weeks. This is the kind of reliability David Miller looks for when he buys for his big rental fleets in the USA.

Why is the quality of the dual-cone seals in my rollers critical for extreme temperature performance?

I have seen rollers fail in the middle of a freezing winter and a burning summer. Most of the time, the culprit is a tiny rubber ring that gave up.

High-quality dual-cone seals (floating seals) keep the oil in and the dirt out, regardless of the temperature. In extreme cold, cheap seals become brittle and leak. In extreme heat, they can soften and lose their shape. Quality seals use premium silicone or nitrile rubber to maintain a perfect seal from -40°C to over 100°C.

The dual-cone seal is the guardian of your roller's bearings. It consists of two metal rings and two rubber "torics." The metal rings rub together to create a seal that can spin. If the rubber torics fail, the oil leaks out. Once the oil is gone, the bearing inside will melt within hours. This is why we at Dingtai only use high-grade alloys 9 for the seal rings and tested rubber compounds for the torics. We want our rollers to work in the deserts of the Middle East and the frozen mines of Canada.

The Role of Precision Polishing

The metal faces of the dual-cone seal must be incredibly flat. We lap these surfaces to a mirror finish. This allows a thin film of oil to sit between them, which prevents the metal from wearing down too fast. If a manufacturer skips this step, the seal will fail early. For our B2B partners 10, this level of detail is what prevents "warranty headaches" and keeps their customers happy.

| Seal Component | Role | Importance in Extreme Temps |

|---|---|---|

| Metal Seal Ring | Creates the primary barrier | Must resist thermal expansion/contraction |

| Rubber Toric | Provides the "spring" force | Must stay flexible in cold and firm in heat |

| Lubricating Oil | Reduces friction between rings | Must flow well in all conditions |

| Housing Fit | Holds the seal in place | Must be machined to tight tolerances |

Maintenance Tip for Seals

If you see oil "misting" or a damp spot on the side of your roller, do not wait. That is the seal telling you it is about to die. Replacing a seal is much cheaper than replacing a whole roller and the labor to install it. Also, always use the correct weight of oil specified by the manufacturer. Oil that is too thick might not reach the seal faces properly during cold starts, causing "dry rub" and damage.

Conclusion

Optimal track performance comes down to choosing high-quality metal, keeping things aligned, and never skipping a wash. By focusing on metallurgy, alignment, recoil systems, and seals, you can double your undercarriage life and save a fortune.

Footnotes

1. Technical overview of induction hardening for enhancing wear resistance in steel. ↩︎

2. Official standards and classifications for steel grades used in industrial applications. ↩︎

3. Expert maintenance tips for identifying and preventing uneven undercarriage wear. ↩︎

4. Strategic guide for fleet managers to optimize heavy equipment undercarriage life. ↩︎

5. EPA resources on understanding and improving fuel efficiency for heavy-duty machinery. ↩︎

6. Best practices for extending the service life of heavy equipment final drives. ↩︎

7. Manufacturer recommendations for maintaining undercarriage systems in top condition. ↩︎

8. Detailed properties and applications of high-tensile spring steel in engineering. ↩︎

9. Searchable database for material properties of various industrial alloys and rubbers. ↩︎

10. Industry news and trends for businesses specializing in earthmoving and construction equipment. ↩︎