Are you finding the Chinese undercarriage market confusing? Prices change and quality varies. As a manufacturer here, I want to share what is really happening on the ground.

From my perspective in Fujian, the Chinese market is defined by three key trends: strong demand from infrastructure, big investments in new manufacturing technology, and a new, serious focus on sustainable, eco-friendly production methods.

These trends affect the quality, price, and availability of the parts you buy. They impact your business. Let's look closer at the details so you can make better purchasing decisions 1.

How is the demand from the domestic Chinese market affecting export prices and lead times?

Do you worry that your orders will be delayed? China's own construction projects 2 are booming. This high domestic demand definitely impacts global buyers like you.

In my experience, strong local demand can sometimes push export prices up slightly due to raw material competition. It also makes stable production planning essential. We prioritize long-term partners to guarantee their lead times.

China's domestic market is massive. New roads, railways, and buildings are constantly under construction. This (Insight 1) creates a huge, steady demand for excavators and their parts. This internal demand is the baseline for all manufacturers, including us.

How Domestic Demand Affects You

When the domestic market is very strong, it competes directly with export orders for two things: raw materials and factory production time.

- Raw Materials (Especially Steel): Everyone needs high-quality steel (Insight 10). When thousands of domestic projects start, the price of steel goes up for everyone. As a manufacturer, I see these price changes weekly. This directly impacts the cost of a track roller or a sprocket.

- Production Capacity: A factory has a limited number of hours in a day. Smaller factories (Insight 1) might take large domestic orders and then delay their export clients. This is a huge pain point for buyers who need stable inventory.

Our Strategy: Prioritizing Stability for Partners

We (Dingtai) operate differently. We are a B2B manufacturer focused on long-term relationships, often with OEM clients 3 and large distributors. We use forecasting based on our partners' needs. This means we secure raw materials in advance and schedule production capacity specifically for our established clients.

This protects you from the biggest shocks. While small price changes are unavoidable, our partners do not face sudden, long delays (Customer feedback 3). A reliable supplier must know how to balance both domestic and export markets.

Here is a simple comparison of what buyers often find:

| Supplier Type | Price Strategy | Lead Time Stability | Quality Control (QC) |

|---|---|---|---|

| Small Factory (Insight 1) | Very Low (to win orders) | Low (Domestic orders may delay exports) | Basic (Inconsistent) |

| Trading Company | Medium | Variable (Depends on their factory) | None (They don't produce) |

| Dingtai (Manufacturer) | Competitive (Stable) | High (We plan for partners) | Strict (ISO9001/SGS) |

This stability is why buyers who value reliable supply chains 4 choose to work directly with established manufacturers. They avoid the pain of unexpected delays.

Are manufacturers investing in new technologies or production methods?

Do you wonder if Chinese parts are made with modern technology? It is a valid concern. The answer is yes, top manufacturers are investing heavily (Insight 2).

Absolutely. From my factory floor, I see huge investments in advanced manufacturing (Insight 2). We use things like automated heat treatment and precision CNC machining. This is key to improving product quality and consistency.

Investment in technology is the biggest difference between a top-tier supplier and a cheap one. Buyers with strong technical backgrounds understand this immediately.

The Old Way vs. The New Way

In the past, many processes relied heavily on manual skill. This creates inconsistency (a major pain point for buyers). One batch of track rollers might be perfect, but the next batch, made by a different shift, might fail early. This is unacceptable for a serious distributor (Customer Pain Point).

Today, leading manufacturers (Insight 7: strengthening domestic brands) are pouring money into automation and new production methods (Insight 2).

Key Technology Investments

Here are the specific technologies we (Dingtai) and other top factories use:

- Automated Heat Treatment: This is the most critical process for durability. Our track links and rollers go through computer-controlled induction hardening. This ensures every single piece has the correct hardness depth and surface strength. This directly fights the pain point of "unstable quality" (Customer feedback 2).

- Precision CNC Machining: All our parts, like idlers and sprockets, are finished on CNC machines. This guarantees that the dimensions are 100% accurate and spectrometers to check the raw steel 5 before it enters production.

- Advanced Quality Control (QC): We have our own labs. We also conduct 100% inspection after production to ensure parts match the OEM specifications 6 (like Caterpillar or Komatsu). (Our profile: ISO9001/SGS).

When a buyer asks me for technical data, like heat treatment depth or material composition, I can provide it. Why? Because our technology measures and controls it. A supplier still using old methods cannot provide this data reliably (Customer Pain Point). This technology is how we build trust and ensure the reliability of every part.

What are the latest developments in materials or design for undercarriage parts?

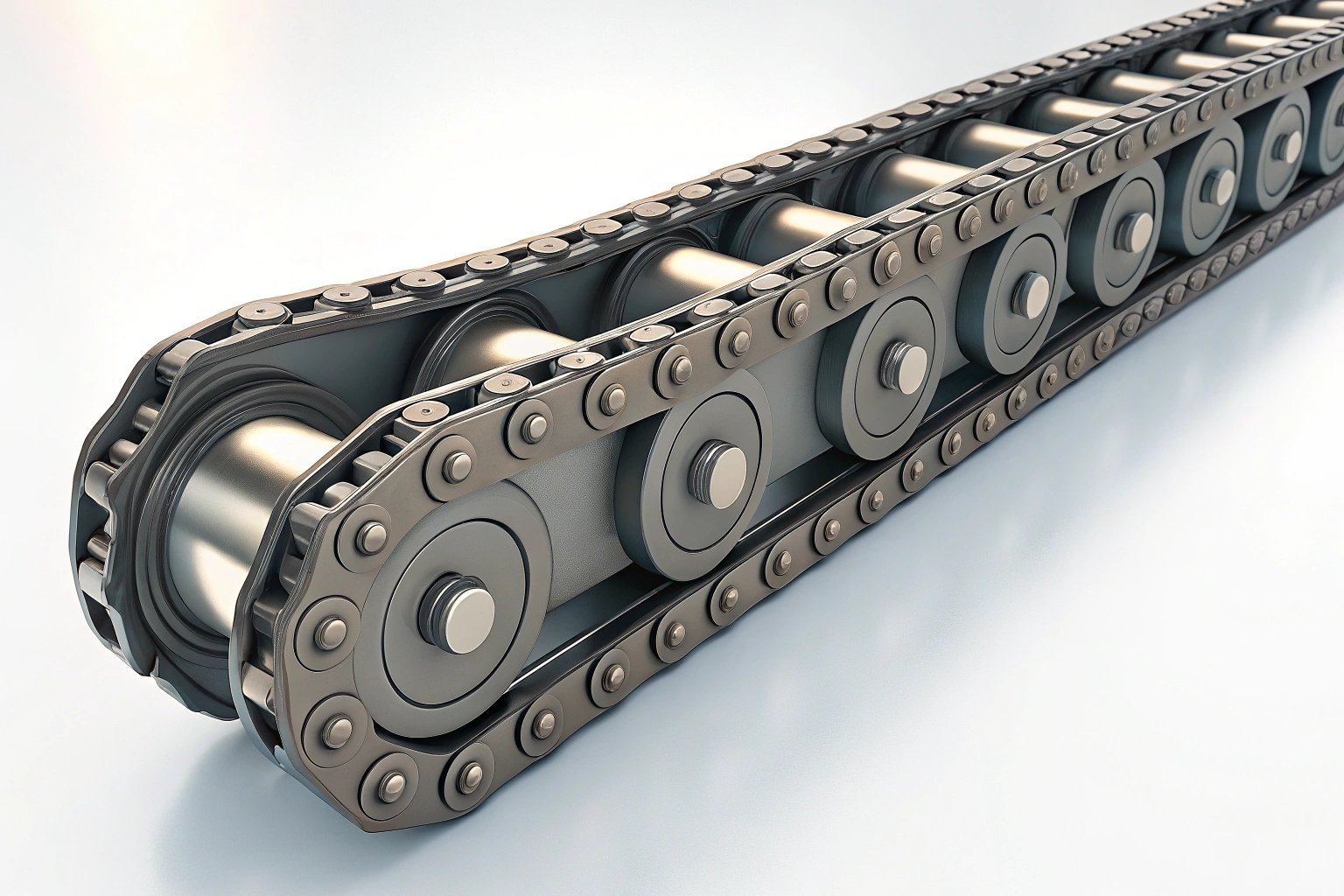

Do you think a track chain is just a piece of steel? It is easy to assume materials have not changed. But the materials and designs are getting much smarter.

From my R&D department, the biggest developments are in new steel alloys and better seal designs. We are focused on making parts last longer, especially in tough conditions (Insight 4: sustainability/durability).

For a technical buyer, this is the most exciting trend. The "look" of an undercarriage part has not changed much, but the "science" inside it has.

Better Materials: Beyond Standard Steel

The biggest change is the use of specialized steel alloys. We are moving beyond simple carbon steel.

- Boric (Boron) Steel: We use this for track chains and track shoes. Adding a tiny amount of Boric (Boron) Steel 7 makes the steel respond much better to heat treatment. The result is a part that is significantly harder and more resistant to wear.

- High-Manganese Steel: Used in parts that experience high impact, like drive sprockets. This material is tough and actually gets harder the more it is impacted (work-hardening).

As one of my clients noted (Customer feedback 4), these upgraded materials can increase wear life by 30% or more. This is a huge selling point for distributors.

Smarter Designs: Solving Old Problems

We are also refining the design of components (Insight 6).

- Advanced Sealing: For track rollers and idlers, the enemy is dirt. We now use advanced seal groups (like duo-cone seals 8). These provide a much better barrier against sand, mud, and water. This keeps the internal lubrication clean, which is the key to a long roller life.

- Optimized Shapes: We use computer modeling (R&D) to optimize the shape of sprocket teeth or the profile of a track link. This ensures smoother operation and more even wear, extending the life of the entire system.

Here is how these new developments compare to standard parts:

| Component | Standard Part | Latest Development (Insight 4) | Benefit for the Buyer |

|---|---|---|---|

| Track Chain | Standard Carbon Steel | Boron Steel Alloy | Higher wear resistance, longer life |

| Track Roller | Basic Seals | Advanced Duo-Cone Seals | Protects lubrication, stops failure |

| Sprocket | Standard Cast Steel | High-Manganese Steel | Hardens with use, resists impact |

We also offer customization (Our profile). If a client has equipment working in highly abrasive sand, we can develop a custom solution. This level of technical support is something only a true manufacturer can offer.

How are environmental regulations in China impacting the manufacturing industry?

Do you worry about the environmental impact of your suppliers? Many people still picture old, smoking factories. That image is changing fast in China.

As a factory owner, I can tell you the regulations are very strict. We must invest in clean production, like advanced wastewater treatment and dust collection. This increases costs, but it ensures sustainable, long-term operation.

This is a very serious topic in China now. The government is enforcing environmental rules very strictly 9. This is not just talk; factories that do not comply are shut down.

The Cost of Compliance

As a manufacturer, we have had to make large investments (Insight 4: sustainability).

- Wastewater Treatment: Our processes, like quenching (heat treatment), use water. All of this water must be treated and cleaned before it is released.

- Dust and Fume Collection: Our foundry (casting) and grinding workshops are now equipped with powerful air filtration systems.

- Energy Efficiency: We are always upgrading to more efficient motors and furnaces to reduce our overall energy use.

These investments add to the cost of production (Insight 5). A factory that ignores these rules can (temporarily) offer a cheaper price.

Why Buyers Should Care

This is a critical point for procurement. A buyer might be tempted by a very low price from a small, unknown factory (Insight 1). But that low price often means they are not following the law.

This creates two huge risks for the buyer:

- Sudden Shutdowns: That cheap factory could be shut down by inspectors tomorrow, with no warning. Your orders will disappear, and your deposit may be lost (Customer Pain Point: delivery delays).

- Reputation Risk: Buyers in the US and Europe (Customer feedback 6) are now asked about their supply chain. Working with a "dirty" supplier is a risk to your brand.

Choosing a supplier that is ISO 9001 and SGS certified 10 (Our profile) proves they are compliant. It is the safe, stable, and sustainable choice.

| Supplier Profile | Environmental Compliance | Supply Chain Risk | Long-Term Cost |

|---|---|---|---|

| Compliant (Dingtai) | High (Invests in treatment) | Low. Stable, legal operation. | Competitive (Reflects true cost) |

| Non-Compliant | None (Ignores rules) | Very High. Risk of sudden shutdown. | High (Lost orders, delays) |

As my clients (Customer feedback 6) start to prioritize eco-friendly parts, they find that working with a compliant manufacturer is the only way to meet their goals.

Conclusion

The Chinese undercarriage market is evolving. It is more technical, more reliable, and more sustainable than ever. We (Dingtai) are proud to be part of this change.

Footnotes

1. Guide on making informed global procurement decisions. ↩︎

2. Data on China's massive domestic infrastructure investments. ↩︎

3. Understanding the role of Original Equipment Manufacturers in supply chains. ↩︎

4. Best practices for building resilient and stable supply chains. ↩︎

5. How spectrometers are used for material verification in manufacturing. ↩︎

6. The importance of parts meeting Original Equipment Manufacturer (OEM) specs. ↩︎

7. Learn about the properties and benefits of boron-alloyed steel. ↩︎

8. See how duo-cone seals work to protect undercarriage components. ↩︎

9. Overview of China's current environmental protection laws for industry. ↩︎

10. What ISO 9001 and SGS certification mean for supplier quality. ↩︎