It is hard to find quality parts that do not break your budget. Downtime costs you money and reputation. As a manufacturer, I see why smart buyers now look to China.

From my 20 years in this business, the main advantages are not just price. It is the combination of massive scale, strong quality control, and incredible flexibility. We deliver durable, customized parts faster than many expect.

You might think "Made in China" only means "cheap." But the reality today is much more complex. Let's break down the specific advantages I see every day from my factory floor here in Fujian 1.

How does the overall cost structure in China compare to other countries like South Korea or Italy?

You need to control costs without sacrificing quality. Paying 30-50% more for parts from other countries is difficult. I want to show you exactly how we manage to provide that value.

China's cost structure is much lower than in South Korea or Italy. I attribute this to lower labor costs, highly efficient local supply chains, and huge economies of scale. We pass these savings directly to our customers.

The most obvious advantage is price. But smart buyers like David Miller, who I often speak with, know that price is different from total cost. Price is what you pay today. Total cost includes the part's lifespan 2, shipping, and reliability.

Chinese manufacturers win on both.

The Components of Cost

Why are our prices often 20-50% lower than European or Japanese brands? It is not magic. It is a structured advantage.

1. Labor Costs: While rising, the cost of skilled technicians 3 and engineers in China is still more competitive than in Germany, Italy, or the US.

2. Raw Materials: China is the world's largest steel producer 4. We have direct, local access to high-quality steel and other raw materials. This cuts down on shipping costs and import tariffs that factories in other countries must pay.

3. Economies of Scale: My factory, Dingtai, and others in our region produce parts 24/7. This massive volume means we can buy raw materials in bulk at lower prices. Our production lines are highly optimized 5, reducing waste and time.

4. Government Support: The government supports the manufacturing sector with infrastructure and favorable policies. This creates a stable environment for us to operate and invest in new technology.

Cost Structure Comparison: China vs. Others

Let's look at a simple comparison. This is based on my experience talking to clients who buy from all over the world.

| Cost Factor | China (e.g., Dingtai) | South Korea | Italy |

|---|---|---|---|

| Labor Cost | Moderate | High | Very High |

| Raw Material Access | Excellent (Local) | Good (Mostly Imported) | Good (Imported) |

| Energy Costs | Moderate | High | High |

| Supply Chain | Highly Integrated | Good | Fragmented |

| Brand Premium | Low / None | Moderate | High |

| Typical Price Index | 100% | 130% - 150% | 140% - 170% |

For a purchasing director, this table shows a clear picture. You are not just saving on the sticker price. You are benefiting from a fundamentally more efficient system. This is not about cutting corners. It is about cutting waste from the system. When I provide a quote, it reflects these real efficiencies. This allows my customers to maintain healthy margins while still providing a durable product to their end-users. It is a key reason why we build long-term relationships.

What are the differences in terms of manufacturing scale and production capacity?

You have large orders and strict deadlines. A small factory cannot keep up, causing delays. I see how China's massive production scale provides the supply security you need.

The difference is huge. From my factory, I see that China's manufacturing scale is unmatched. We can produce thousands of rollers or track chains in weeks, not months. This flexible, large-scale capacity means we handle huge OEM and aftermarket orders simultaneously.

When we talk about "scale" in China, we are not just talking about a single large factory. We are talking about entire cities and provinces dedicated to manufacturing. Here in Fujian, we are part of a massive industrial cluster 6 for construction machinery parts.

The Power of Industrial Clusters

This clustering is our secret weapon. My factory, Dingtai, does not operate in isolation.

- We have heat treatment specialists down the road.

- We have forging plants nearby.

- We have logistics hubs built specifically for heavy parts.

This ecosystem means we can scale up production incredibly fast. If I get a massive order from an OEM client, I can coordinate with my local partners instantly. This is a level of flexibility that is hard to find elsewhere. It also means we are resilient. During global supply chain shocks 7, our local network often stays stable.

Flexible Capacity: OEM, Aftermarket, and Customization

Our capacity is not just big; it is also flexible. At Dingtai, we run production lines for two main models:

1. OEM Manufacturing: We produce parts for well-known global brands. These require strict adherence to the brand's exact specifications and quality standards.

2. Aftermarket (Our Brand): We produce parts under our own "Dingtai" brand. These offer OEM-level quality directly to distributors and large end-users.

This dual capability means our lines are always running and optimized. It also means we have the technical skill to handle complex jobs.

A client like David often needs custom parts for older or specialized machines. We can do that. Because our R&D team and production lines are in the same place, we can design, tool, and produce a custom idler or sprocket 8 quickly. Often, we can move from drawing to finished product in just a few weeks. This solves a major headache for distributors who serve diverse markets.

Here is what our typical production capacity looks like:

| Product Line | Standard Production (Units/Month) | Surge Capacity (Units/Month) | Typical Lead Time |

|---|---|---|---|

| Track Rollers | 30,000 | 45,000 | 15-30 days |

| Track Chains (Links) | 100,000 | 150,000 | 20-35 days |

| Sprockets/Idlers | 10,000 | 15,000 | 20-30 days |

This scale means we can honor our delivery promises. This stability is why long-term partners trust us with their core inventory. They know we can deliver.

Is there a difference in the level of quality and technology I can expect?

You worry that a lower price means lower quality. A failed part costs you customers and credibility. I live by quality control every day, and the standards here will surprise you.

Yes, but perhaps not how you think. In my experience, top Chinese manufacturers like Dingtai now match or exceed global quality standards. We invest heavily in technology, R&D, and strict quality control, like our ISO9001 certification.

Let's be direct. Twenty years ago, the "Made in China" label sometimes meant inconsistent quality. Today, that idea is completely outdated. For any serious manufacturer like us, quality is not negotiable. It is the only way to survive.

My customers, like David, are technical experts. They have 20+ years of experience. They will not accept parts that fail. They ask for material reports and heat treatment data, and we provide them. This transparency builds trust.

Investment in Technology and R&D

We are not just an assembly line. At Dingtai, we have over 20 professional technicians. Our R&D team works with new materials and advanced manufacturing processes.

- Advanced Metallurgy: We use high-strength steel (like 40MnB) 9 and cast iron. Our processes are designed for maximum wear resistance. We do not use cheap materials.

- Automated Production: We use automated forging, precision CNC machining, and robotic welding. This automation does not just speed things up. It creates incredible consistency. Every part is made to the exact same tolerance, every time.

- Heat Treatment: This is critical for undercarriage parts. Our heat treatment processes are carefully controlled to create a hard-wearing surface (for low wear) while keeping a strong, ductile inner core (to prevent cracking). This extends the part's life in tough conditions.

The Quality Control (QC) Process

A technical buyer's worst nightmare is inconsistent quality—batches that vary. We solve this with a multi-step QC process.

1. Raw Material Inspection: Before any steel enters our factory, we test it. We use spectrometers to check its exact chemical composition. If it's not perfect, we reject it.

2. In-Process Inspection: We check parts at every stage of production. We check dimensions after machining. We check hardness after heat treatment.

3. Final Inspection: We perform a 100% quality check on finished goods. This includes dimensional accuracy, hardness testing, and visual checks for any flaws.

We are an ISO9001 and SGS certified company 10. This is not just a piece of paper. It is the system we use every single day to ensure reliability. This focus on quality is why our customers trust us. They know that a part from Dingtai will fit, perform, and last. It reduces their after-sales headaches, which is a core pain point we work to solve.

How does the supply chain and logistics infrastructure in China provide an advantage?

You need reliable delivery dates. A late shipment stops your entire operation. My factory is located within a world-class logistics network that ensures we deliver on time.

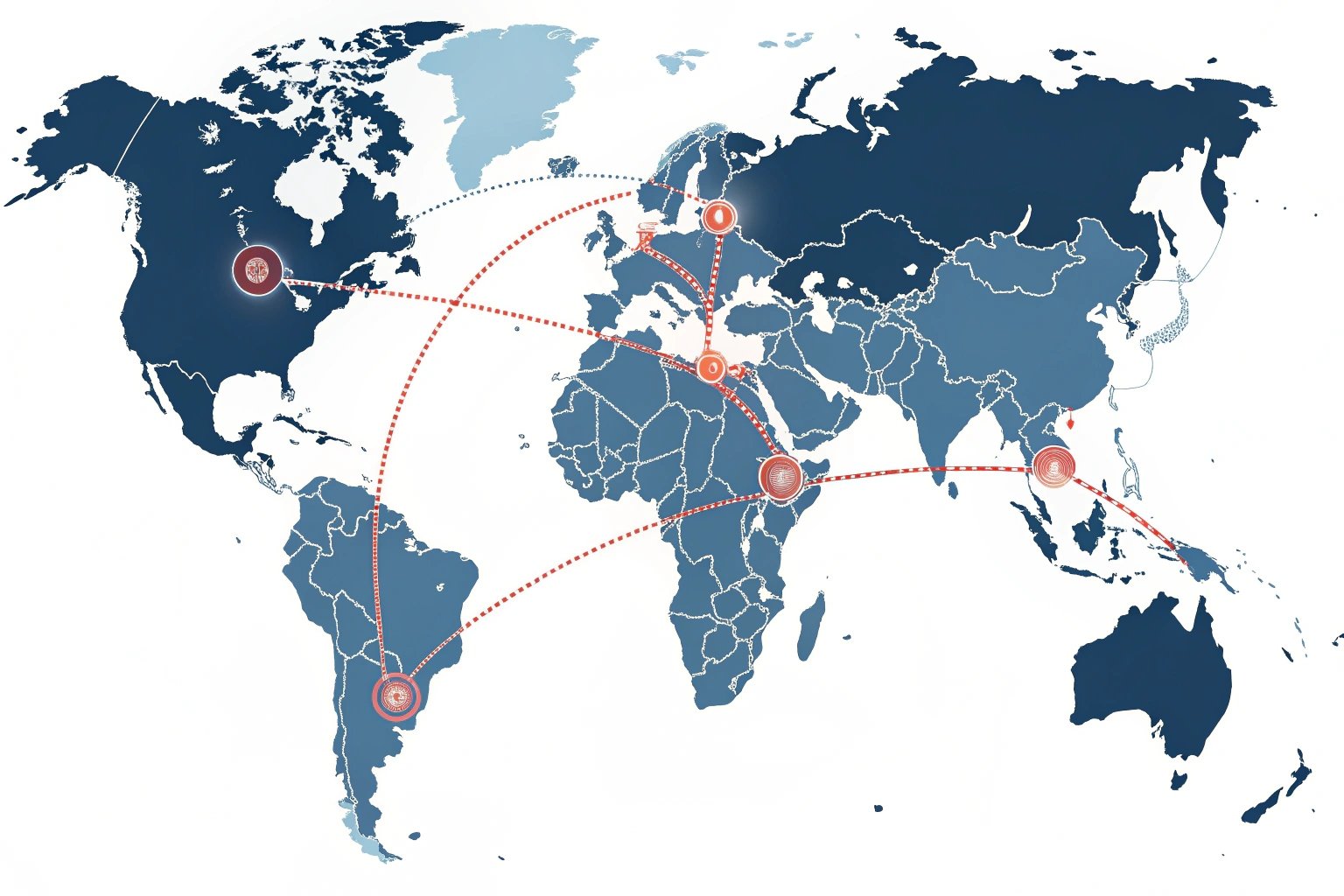

From my location in Fujian, I see the advantage clearly. China has the world's most advanced ports and an integrated domestic supply chain. This means we get raw materials fast and ship finished goods to any continent efficiently.

A great part is useless if it is stuck on a dock. For a purchasing director, a reliable delivery date is just as important as the quality of the part itself. China's advantage here is enormous.

The Domestic Supply Chain

As I mentioned, our factories are in industrial clusters. This is a huge logistics advantage.

- Reduced Inbound Freight: We are close to our steel suppliers. We get raw materials in days, not weeks.

- Specialized Services: We have local partners for heat treatment, coating, and packing. Everything is close.

- Resilience: Because this network is so deep, if one supplier has a problem, we have backups. This is why many of us were able to maintain a stable supply even during the global pandemic.

This integrated system reduces delays before the product even leaves our factory. We control the timeline.

World-Class Global Logistics

My factory is in Fujian Province. We are very close to Xiamen Port, one of the top 15 busiest container ports in the world. We are also near other major ports like Shanghai and Shenzhen.

This gives us and our customers incredible flexibility. We can ship to any major port in North America, Europe, South America, or Southeast Asia with multiple sailings per week. We are not dependent on a single port or shipping line.

What This Means for You

For a buyer like David, this means:

- Reliable Timelines: We can give you an accurate "ex-factory" date.

- Clear Tracking: We provide transparent order tracking from our door to yours.

- Cost-Effective Shipping: The high volume of shipping from China keeps freight costs competitive.

- One-Stop Shop: We handle everything from production to quality control to port delivery. This simplifies your purchasing process. You do not need to coordinate with 3-4 different suppliers.

Here is a look at the streamlined process we manage:

| Step | Action | Key Advantage |

|---|---|---|

| 1. Order Confirmed | We schedule production and source raw materials. | Local access to steel (fast). |

| 2. Manufacturing | Forging, machining, heat treatment. | In-house and cluster partners (fast). |

| 3. QC & Packing | 100% inspection and export-grade packing. | Guarantees quality on arrival. |

| 4. Port Delivery | Trucking to nearby port (e.g., Xiamen). | Short distance (1-2 days). |

| 5. Global Shipping | Loaded onto container ship. | Frequent, reliable sailings. |

This entire system is built for efficiency. It is how we deliver high-quality, heavy-duty parts from our factory floor in China to your warehouse in the US or Europe, on time.

Conclusion

In summary, Chinese manufacturers offer a powerful mix: competitive cost, massive scale, high quality, and a robust supply chain. We are long-term, reliable partners for your business.

Footnotes

1. Explore Fujian's role as a major industrial and manufacturing hub in China. ↩︎

2. Understand Total Cost of Ownership (TCO) in heavy machinery procurement. ↩︎

3. Comparison of global manufacturing labor rates and skilled technician costs. ↩︎

4. Data on global steel production and China's leading role in the market. ↩︎

5. Learn about optimized production lines and lean manufacturing principles. ↩︎

6. What are industrial clusters and how do they create a competitive advantage? ↩︎

7. Analysis of recent global supply chain shocks and strategies for resilience. ↩︎

8. See examples of custom forging and machining for specialized heavy equipment. ↩︎

9. Technical specifications and applications for 40MnB high-strength alloy steel. ↩︎

10. Learn about the standards and verification process for SGS certification. ↩︎