I know how frustrating it is when your mini excavator breaks down in the middle of a big job. If your tracks are slipping or rollers are seizing, you are losing money every hour.

The best undercarriage parts for mini excavator performance include durable drive sprockets, heat-treated rollers, and high-quality tracks. Choosing parts that match your specific model ensures better traction, less fuel waste, and a much longer lifespan for your machine.

Choosing the right parts is not just about the price tag. It is about making sure your machine can handle the mud, rocks, and long hours without failing you. Let's look at how specific high-quality parts save you time and money.

How does the use of heat-treated alloy steel in my drive sprockets reduce my long-term maintenance costs?

I see many people buy cheap sprockets only to watch the teeth wear down to points in just a few months. It is painful to pay for repairs twice when you could have done it once.

Heat-treated alloy steel sprockets reduce maintenance costs by providing superior surface hardness that resists "hooking" and wear. This process ensures the sprocket maintains its shape longer, preventing it from stretching your track links or causing premature rubber track failure.

When we talk about heat treatment 1, we are talking about the "muscle" of the steel. In our factory at Dingtai, we use deep induction hardening 2. This isn't just a surface coating; it changes the structure of the metal. If the steel is too soft, the grit and sand from your job site act like sandpaper, grinding the teeth away. If the teeth lose their shape, they no longer fit into the track links 3 correctly. This causes a "jumping" effect that puts massive stress on your final drive motor.

Comparison of Material Durability

| Material Type | Hardness Level (HRC) | Expected Lifespan | Impact Resistance |

|---|---|---|---|

| Standard Carbon Steel | 25-30 | Short | Low |

| Surface Hardened Steel | 40-45 | Medium | Moderate |

| Deep Heat-Treated Alloy | 50-55 | Long | High |

Think about your final drive hub 4. It is one of the most expensive parts of your mini excavator. A worn sprocket forces the motor to work harder to turn the track. By investing in alloy steel that stays sharp, you are actually protecting the motor. This avoids those $3,000 repair bills for a new final drive. We have seen customers in the US, like David, switch to our heat-treated parts and see their replacement intervals double. This means fewer days in the shop and more days making money on the job site.

Key Benefits of Heat Treatment

- Precision Fit: The teeth keep their original profile, so they don't "chew" your tracks.

- Core Strength: The center of the part remains tough so it doesn't crack under heavy loads.

- Wear Resistance: It handles abrasive soil and gravel much better than standard iron.

What are the advantages of using "heavy-duty" series rollers for mini excavators used in demolition?

I have stood on demolition sites where the ground is covered in jagged concrete and rebar. In those conditions, a standard roller just won't last more than a few weeks before it starts leaking oil.

Heavy-duty rollers feature reinforced shells and superior sealing systems that prevent debris from entering the bearings. In demolition, these rollers support the extra weight of attachments like hammers while resisting the constant impact of traveling over sharp rubble.

Demolition work is brutal on the bottom of your machine. When you use a hydraulic breaker 5, the vibration goes straight through the tracks and into the rollers. Standard rollers often have thin walls that can dent or crack. Our heavy-duty series uses a thicker forged shell 6. This thickness allows the roller to absorb the shock without deforming. If the shell stays round, the bearings inside stay aligned. This is the secret to a roller that doesn't seize up when you are in the middle of a pile of debris.

Why Sealing Matters in Demolition

The biggest enemy of a roller is "fines"—the tiny dust from crushed concrete. If this dust gets past the seal, it mixes with the oil and creates a grinding paste. This destroys the bronze bushings 7 in days. Our heavy-duty rollers use "lifetime" seals that are tested for 100% leak-proof performance. We make sure the tension is perfect so no dust gets in, but the roller still turns easily.

Roller Performance Features

| Feature | Standard Roller | Heavy-Duty Roller |

|---|---|---|

| Shell Wall Thickness | 8mm - 10mm | 12mm - 15mm+ |

| Seal Type | Standard O-ring | Dual-Mirror Floating Seal |

| Lubrication | Grease | High-Grade Synthetic Oil |

| Load Capacity | 100% | 130% |

Using these rollers means you don't have to check your undercarriage every two hours for leaks. You can focus on the demolition work. For a procurement manager like David, this reliability is the difference between a profitable contract and a loss due to equipment downtime.

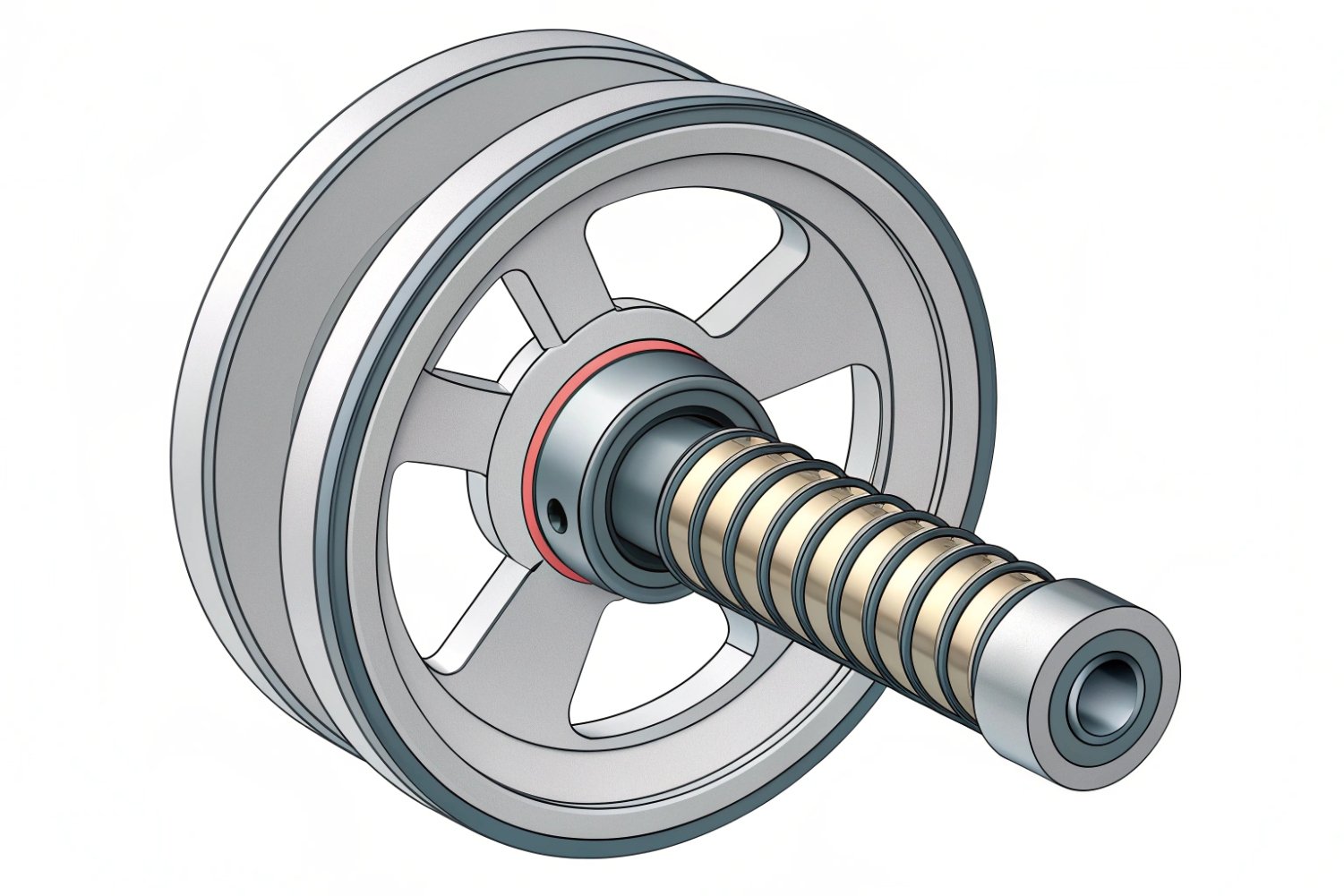

How can I ensure my replacement idlers provide the correct vibration dampening for my operator's comfort?

I have heard many operators complain about back pain after a long shift because the machine feels "stiff." Often, the culprit is a cheap idler that doesn't fit the tensioning system 8 correctly.

To ensure proper vibration dampening, choose idlers with precision-machined shafts and high-quality tensioning springs. A well-built idler acts as a shock absorber, smoothing out the movement of the track and reducing the "chatter" felt in the operator's cab.

The idler is more than just a wheel at the front of your track; it is the gatekeeper of your track tension. If the idler is out of round or has play in the bearings, the track will vibrate every time it rotates. This vibration travels through the frame and into the seat. In our engineering department, we focus on the fit between the idler and the yoke 9. If the gap is too large, the idler will wobble. That wobble creates a harmonic vibration that wears out your pins and bushings faster and makes the ride miserable for the operator.

The Role of the Tensioning Cylinder

The idler works with a grease-filled tensioning cylinder and a large spring. If you buy a replacement idler that isn't perfectly compatible with your OEM spring, it won't sit right.

- Check the Alignment: The idler must be perfectly centered.

- Inspect the Surface: A smooth, hardened path on the idler prevents the track from "jumping" as it enters the frame.

- Oil Quality: We use specialized oil that stays thin in cold weather, ensuring the idler spins freely even on a freezing morning in the Northeast.

When the operator is comfortable, they are more productive. They can work faster and more accurately. By choosing a precision idler, you are investing in both your machine's health and your employee's health. It is a small detail that makes a huge difference in how the machine feels during a 10-hour day.

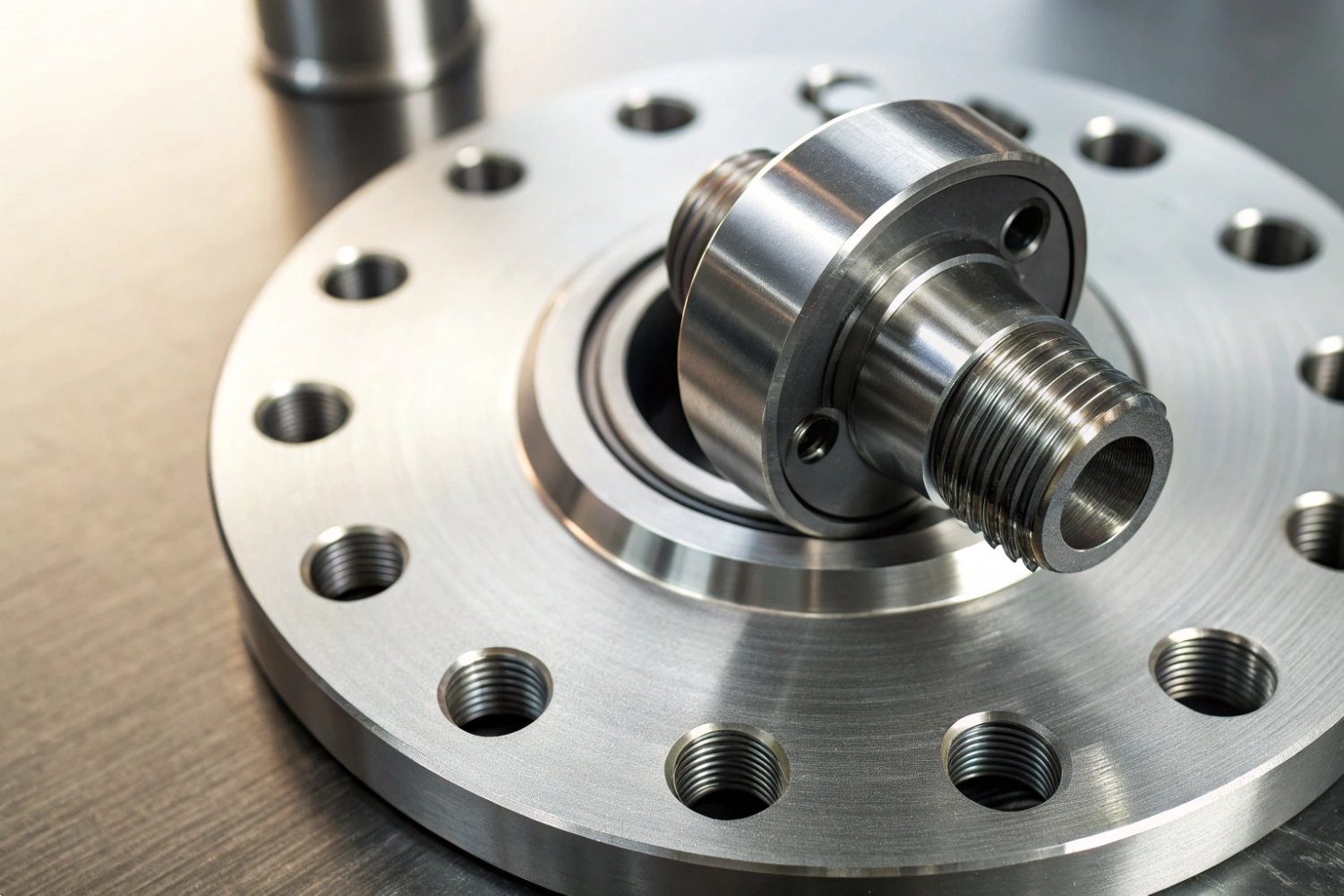

Why is the precision of the bolt-on sprocket holes vital for preventing damage to my final drive hub?

I once saw a brand-new final drive ruined because the customer forced a sprocket onto the hub that didn't quite line up. It felt "close enough," but that tiny error cost him thousands of dollars.

Precise bolt-on sprocket holes ensure that the mounting bolts are perfectly centered and tightened. If the holes are even 1mm off, it creates uneven torque on the final drive hub, leading to snapped bolts, oil leaks, and permanent damage to the motor housing.

At Dingtai, we use CNC 10 drilling for every sprocket. This means every hole is exactly where the OEM specifications say it should be. Why does this matter? When you have 9 or 12 bolts holding a sprocket to a motor, they all need to share the load. If one hole is slightly off, that bolt carries too much weight, or it forces the sprocket to sit crooked. A crooked sprocket will "wobble" as it turns. This wobble puts a side-load on the final drive bearings and seals. Eventually, the seal will fail, the gear oil will leak out, and the gears inside the motor will grind themselves to pieces.

Impact of Poor Hole Precision

| Issue | Immediate Result | Long-Term Damage |

|---|---|---|

| Misaligned Holes | Bolts are hard to thread | Bolts snap under load |

| Uneven Surface | Sprocket "wobbles" | Final drive seal failure |

| Over-sized Holes | Sprocket shifts during travel | Hub mounting flange wears out |

How to Verify Quality

When you receive a sprocket, it should slide onto the hub easily. You should never have to use a hammer to force it on. The bolts should thread in by hand before you use a torque wrench. If you have to fight the part to get it on, it is the wrong part. We provide David and our other clients with technical drawings to confirm these measurements before we ever ship a single box. This transparency builds trust and ensures the machine stays in the field.

Conclusion

The best undercarriage parts are those that fit perfectly and use high-grade materials like heat-treated alloy steel. Investing in quality sprockets, rollers, and idlers prevents expensive repairs and keeps your machine running.

Footnotes

1. Comprehensive overview of how heat treatment alters steel properties for industrial durability. ↩︎

2. Technical explanation of induction hardening for localized surface strength in heavy machinery. ↩︎

3. Expert discussion on identifying and managing wear patterns in excavator track links. ↩︎

4. Maintenance guide for protecting final drive hubs and hydraulic motors from failure. ↩︎

5. Information on high-impact hydraulic breaker attachments used in demolition projects. ↩︎

6. Detailed look at the forging process for creating high-strength hollow metal components. ↩︎

7. Technical specifications and benefits of using cast bronze bushings in mechanical assemblies. ↩︎

8. Industry guide for maintaining proper undercarriage tension to extend component life. ↩︎

9. Overview of idler and yoke assemblies for various heavy equipment models. ↩︎

10. Guide to CNC machining processes and their role in precision parts manufacturing. ↩︎