I know the frustration of a machine sitting idle because a simple roller failed and there is no replacement in the warehouse. For me, every hour of downtime is a direct hit to the budget.

The five essential undercarriage parts to stock for an excavator are track chains, track shoes, rollers, idlers, and sprockets. Keeping these on hand helps minimize downtime and keeps the machine mobile when wear or damage occurs. These components bear the most stress during operation.

Choosing the right parts and knowing when to replace them can save you thousands of dollars in repair costs. Let me share my experience on which parts deserve a spot on your shelf and why they are so important for your business.

Why are track chains and rollers the most critical wear items for my inventory management?

In my 20 years of working with heavy machinery, I have seen that track chains and rollers are the parts that work the hardest. They are constantly moving and carrying the full weight of the machine through mud and rocks.

Track chains and rollers are critical because they are the primary moving parts that experience the most friction. Track chains serve as the backbone of the undercarriage, while rollers support the machine's weight. If these fail, the entire excavator stops moving, causing expensive project delays.

The Backbone of Movement: Track Chains

I often tell my clients that the track chain is like the spine of the excavator. It links everything together. When the pins and bushings 1 inside the chain wear down, the chain stretches. This is what we call "pitch extension." Once a chain stretches too much, it starts to damage the sprockets and idlers. I always keep a few spare link assemblies in stock because a snapped chain in the middle of a job site is a nightmare to fix without parts ready.

Supporting the Weight: Track Rollers

Rollers are the unsung heroes. They sit at the bottom and take all the pressure. Because they are close to the ground, they are always covered in dirt. This dirt can get past the mechanical seals 2 and ruin the internal bearings. When a roller seizes up, it stops turning. Instead of rolling, it starts to drag against the track chain. This creates a flat spot on the roller and grinds down your expensive track links. Replacing a single roller is cheap; replacing a whole set of links because of a bad roller is not.

Why Quality Matters for These Parts

When I choose parts for my inventory, I look at the heat treatment process 3. For example, at Dingtai, we ensure our rollers have deep hardening. This means the metal is strong deep inside, not just on the surface. If you buy cheap parts without good heat treatment, they will wear out in half the time.

| Part Name | Primary Function | Common Failure Sign |

|---|---|---|

| Track Chain | Connects shoes and provides movement | Chain stretching or "snaking" |

| Bottom Roller | Supports machine weight | Oil leaking or seized bearing |

| Carrier Roller | Prevents top chain sag | Flat spots on the rim |

How many spare sprocket segments should I keep on hand for a medium-sized excavator fleet?

I have noticed that many fleet managers forget about sprockets until the teeth are as sharp as shark fins. By then, the sprocket has already started eating away at the new track bushings you just installed.

For a medium-sized fleet, you should keep at least two full sets of sprocket segments or rims per machine model. Since sprockets drive the tracks, worn teeth cause the chain to jump or slip. Having spares ensures you can replace them the moment the tooth profile becomes hooked.

Understanding Sprocket Wear

The sprocket is the part that actually pushes the machine forward. It engages with the bushings of the track chain. Over time, the friction wears the teeth down. If you look at your sprockets and see the teeth looking "hooked" or very thin at the tips, they are done. I always recommend changing sprockets when you put on a new set of track link assemblies 4. If you put a new chain on an old, worn sprocket, the old sprocket will ruin the new chain very quickly.

Segmented vs. Solid Sprockets

Many modern machines use segmented sprockets 5. These are great because you don't have to take off the whole track to change them. You can just unbolt the segments. I suggest stocking the bolts and nuts along with the segments. In my experience, these bolts are under a lot of torque and can sometimes break or stretch during removal.

Inventory Strategy for Sprockets

If you have five machines that use the same part number, you don't need five sets. But you do need enough to cover the most active machines. I usually suggest a 20% rule. If you have 10 machines, keep 2 sets of sprockets ready. This balances the cost of inventory with the risk of downtime.

Key Factors for Sprocket Life

- Proper Tension: Tracks that are too tight put extra pressure on sprocket teeth.

- Soil Conditions: Sandy soil acts like sandpaper between the sprocket and the chain.

- Operator Habits: Fast reversing causes faster wear on the back side of the sprocket teeth.

What makes idlers and tensioning cylinders essential for preventing track-off-the-rail incidents?

There is nothing worse than a "thrown track." I have spent many hours in the mud trying to put a track back on a machine. Most of the time, the problem started with a bad idler or a leaking tension cylinder.

Idlers and tensioning cylinders are essential because they maintain the correct track tension and alignment. An idler guides the chain, while the cylinder uses grease pressure to keep it tight. If these components fail, the track becomes loose and can easily slip off the rollers.

The Role of the Front Idler

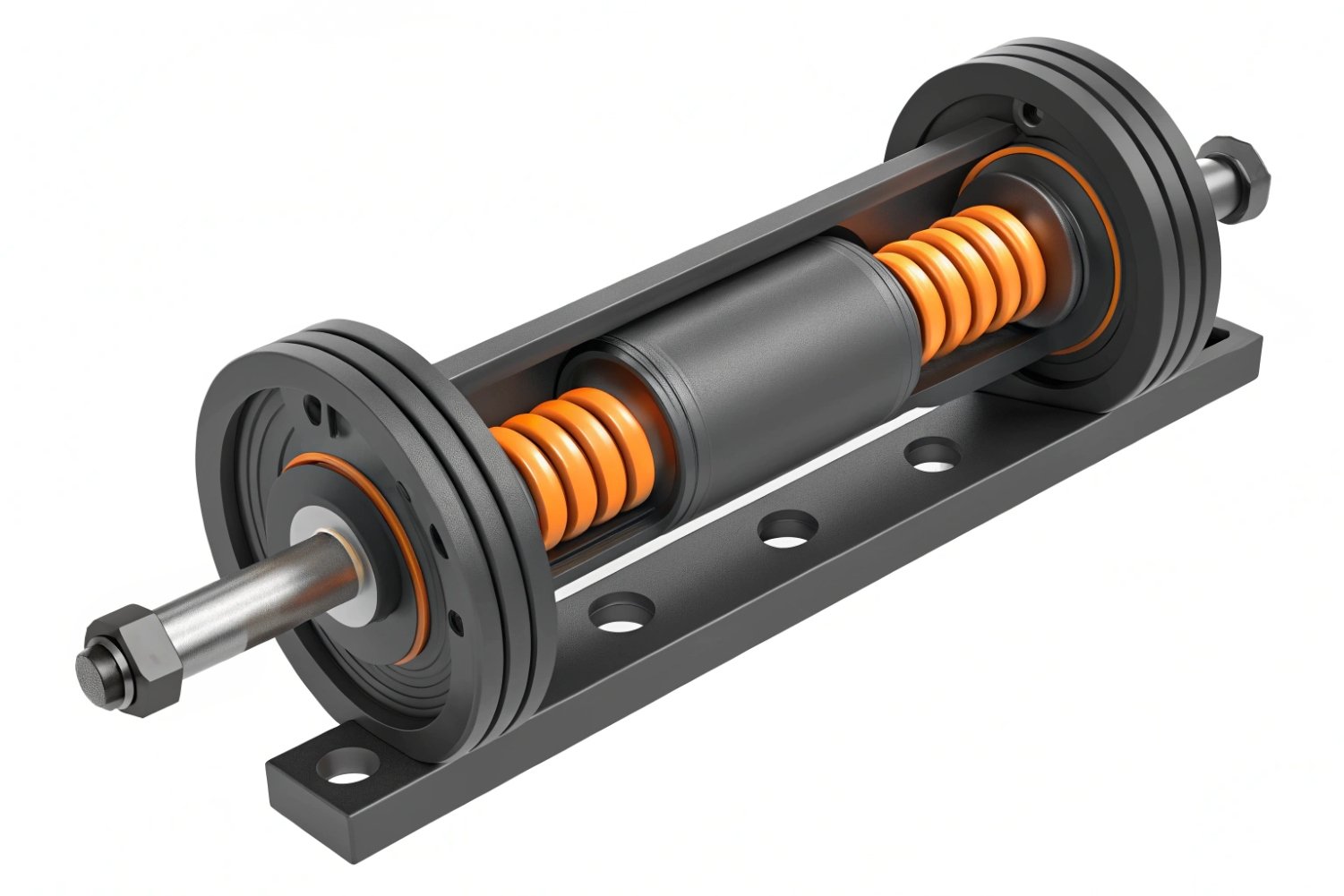

The idler sits at the opposite end of the sprocket. Its job is to guide the track in a straight line. Inside the idler, there are heavy-duty recoil springs 6 and a slide frame. If the idler gets wobbly because the internal bushings are worn, the track will start to wander. Once it wanders too far, it pops off. I keep idlers in stock because they are heavy and can take a long time to ship. Having one ready can save you days of waiting.

The Tensioning System

The track adjuster cylinder 7 is what actually pushes the idler forward to tighten the track. It uses a simple grease fitting. I often see these fail because the seals leak. When the seal leaks, you can pump grease in all day, but the track will stay loose. This is why I also recommend stocking seal kits for these cylinders. It is a small item that prevents a huge problem.

Preventing Damage with Recoil Springs

The recoil spring is part of the idler assembly. It protects the machine when a rock gets caught in the tracks. The spring compresses to absorb the shock. If this spring breaks, there is nothing to absorb that impact, and you might crack your excavator track frame 8 or break a final drive. In my 20 years, I have seen broken springs cause some of the most expensive repairs in the industry.

Comparison of Tensioning Components

| Component | Function | Maintenance Task |

|---|---|---|

| Front Idler | Guides the track chain | Check for side-to-side play |

| Tension Cylinder | Adjusts track tightness | Inspect for grease leaks |

| Recoil Spring | Absorbs impact shocks | Look for cracks or rust |

How do I determine the right quantity of track shoe bolts to order for a complete undercarriage overhaul?

I have seen people buy thousands of dollars in tracks and then try to reuse the old bolts. This is a big mistake. I always tell my customers: if you are changing the shoes, change the bolts.

To determine the right quantity of track shoe bolts, multiply the number of shoes per side by the number of bolts per shoe, then add 10% for spares. For a standard medium excavator with 45 shoes per side and 4 bolts per shoe, you would need 360 bolts plus extras for the complete machine.

Why You Can't Reuse Bolts

Track bolts are "stretched" when they are tightened to the correct torque. This helps them stay tight under the vibration of a construction site. Once they are stretched and then removed, they lose their strength. If you reuse them, they are likely to snap or loosen up. When a bolt loosens, the track shoe starts to move. This movement will wallow out the holes in both the shoe and the track link, ruining both parts.

Counting the Parts

I find it easiest to use a simple chart. Most excavators have between 40 and 50 shoes on each side. Each shoe usually has 4 bolts. So, for one side, you are looking at about 180 to 200 bolts. I always keep a box of extra fastener hardware 9 in the shop. They are cheap compared to the cost of a lost shoe.

Choosing the Right Grade

Not all bolts are the same. I only use Grade 12.9 bolts 10 for undercarriages. They have the high tensile strength needed to handle the weight of a 30-ton machine. When I talk to buyers like David Miller, they always ask about the material and the heat treatment of the hardware. They know that a cheap bolt can cause a thousand-dollar failure.

Inventory Checklist for an Overhaul

- Total Shoes: Count both sides.

- Bolts per Shoe: Usually 4, but some heavy-duty models use more.

- Extra Stock: Always keep 10% more than you need for the job.

- Nut Count: Ensure you have a matching nut for every bolt.

Conclusion

Stocking the right parts is about being prepared for the inevitable wear of heavy work. Focus on track chains, shoes, rollers, idlers, and sprockets to keep your fleet moving.

Footnotes

1. Expert forum discussions on identifying wear in track chain pins and bushings. ↩︎

2. Technical overview of high-performance seals used in heavy machinery rollers. ↩︎

3. Science behind induction hardening and heat treatment for durable steel parts. ↩︎

4. Manufacturer guide on identifying the lifecycle of track link assemblies. ↩︎

5. Comparison of segmented vs solid sprocket designs for heavy equipment. ↩︎

6. Importance of recoil springs in protecting excavator undercarriage structural integrity. ↩︎

7. Industry insights on maintaining track adjusters and hydraulic tension cylinders. ↩︎

8. Detailed encyclopedia entry on the components of heavy equipment track frames. ↩︎

9. Catalog of industrial fasteners and high-strength hardware for construction. ↩︎

10. Technical specifications and strength ratings for Grade 12.9 metric fasteners. ↩︎