Managing a fleet of Cat dozers and excavators often feels like a race against time and wear. I have spent years helping fleet managers identify the core components that keep their machines moving while avoiding the high costs of downtime.

The five most essential Cat undercarriage parts you need today are track chains (link assemblies), track shoes, track rollers (bottom rollers), carrier rollers (top rollers), and idlers/sprocket segments. These components form the structural backbone and drive system of your machine, ensuring traction, weight distribution, and power transfer.

Maintaining a healthy undercarriage is the best way to protect your investment. When one of these five parts fails, it often causes a chain reaction that destroys the rest of the system, leading to expensive repairs that could have been avoided with a smart stocking plan 1.

Why are "SALT" (Sealed and Lubricated Track) chains the most critical upgrade for my Cat machine?

I often tell my clients that if you ignore your track chains, you are essentially ignoring the heart of your machine's mobility. In my experience, switching to Sealed and Lubricated Track 2 (SALT) chains is the single most effective way to extend the life of your entire undercarriage.

SALT chains are critical because they use internal lubrication to eliminate friction between the pin and bushing. This design prevents "track stretch" or pitch extension, which protects your sprockets and rollers from premature wear caused by a mismatched track geometry.

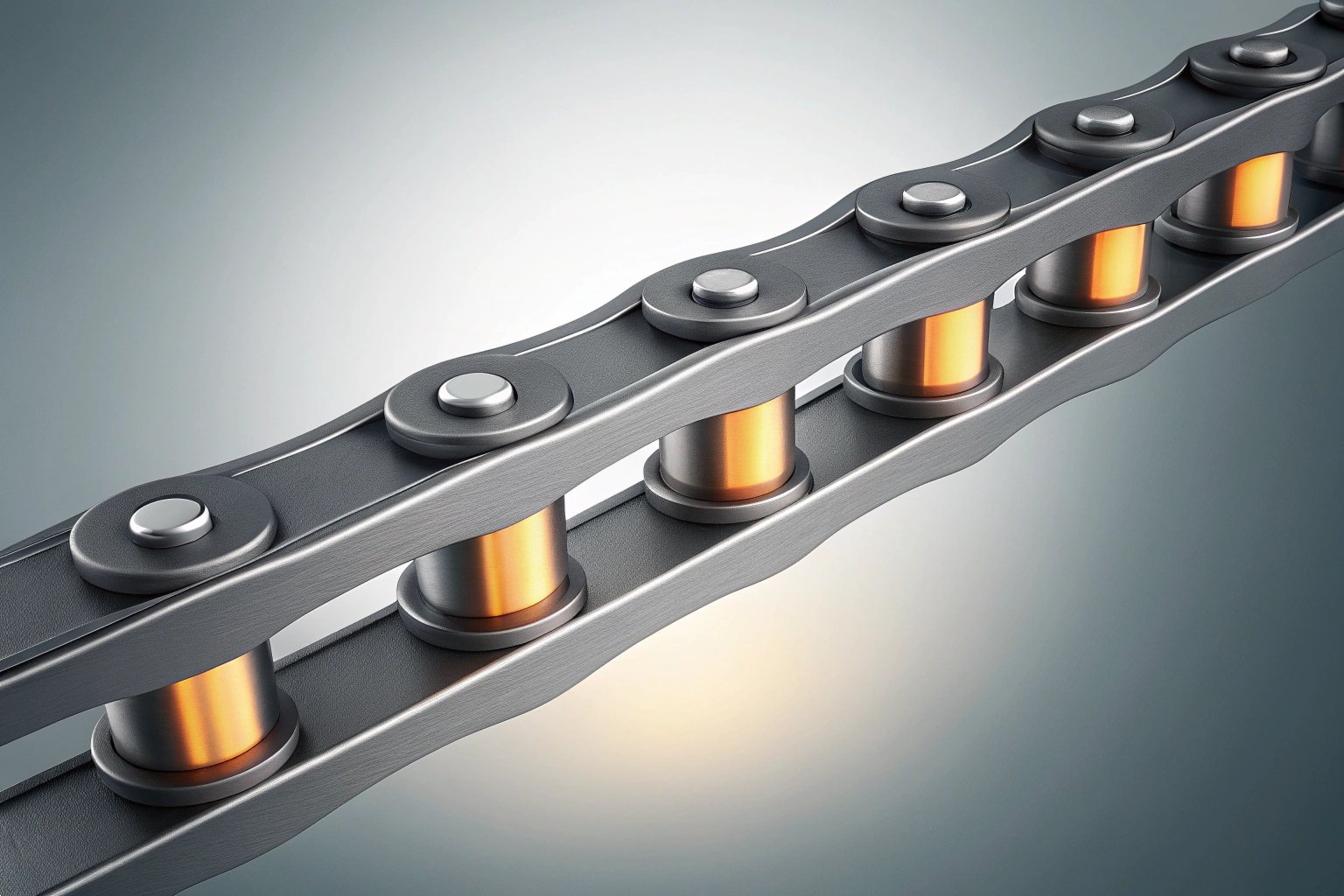

The track chain 3 is the backbone of the entire assembly. It consists of links, pins, and bushings that must work together perfectly. In a standard "dry" chain, the metal-on-metal contact between the pin and the bushing creates heat and wear every time the track rotates. Over time, this wear increases the distance between the pins. This is what we call "pitch extension." Once the pitch changes, the chain no longer fits the sprocket teeth correctly, and the sprocket starts to "hook" or grind down the bushings.

The Anatomy of a SALT Chain

| Component | Function | Benefit of Lubrication |

|---|---|---|

| Pin | Acts as the hinge for the link | Reduced friction prevents internal thinning. |

| Bushing | Protects the pin and engages the sprocket | Stays round longer, maintaining proper pitch. |

| Seal | Keeps oil in and dirt out | Prevents abrasive particles from entering the joint. |

At Dingtai, we focus heavily on the seal quality of our SALT chains. If a seal fails, the oil leaks out, and the "lubricated" chain becomes a "dry" chain almost instantly. This is why we use premium seals that can handle the extreme pressure of heavy-duty mining and construction sites. When you invest in a quality SALT chain, you are not just buying a part; you are buying hundreds of extra hours of machine uptime.

Why Material Choice Matters

We use deep-hardening steel 4 for our links to ensure they can withstand the constant pounding against the rollers. Our heat treatment process ensures that the "rail" of the link—the part that touches the roller—is hard enough to resist wear but the core remains tough enough to not crack under heavy loads. If you are working in abrasive soil, like the laterite 5 found in many mining regions, this hardness is your first line of defense.

How do I evaluate the seal quality in my Cat-style bottom rollers to prevent premature bearing failure?

I have seen countless bottom rollers fail because a simple seal couldn't keep out the mud and water. When I talk to buyers like David, I emphasize that the roller is the workhorse of the undercarriage, carrying the full weight of the machine while spinning in the most abrasive conditions imaginable.

To evaluate seal quality, you must look for "Duo-Cone" or "Lifetime" mechanical seals made from high-grade alloyed cast iron. These seals must have precision-lapped surfaces that create a watertight barrier, preventing oil leaks and keeping contaminants away from the internal bearings.

The bottom roller 6, or track roller, is constantly submerged in mud, water, and grit. If the seal fails, the oil that lubricates the internal bushings and shafts leaks out. Without lubrication, the heat builds up rapidly, the metal seizes, and the roller stops turning. A "frozen" roller will then act like a grindstone against your expensive track links, wearing them down in a matter of days.

Signs of High-Quality Roller Construction

- Shell Hardness: The outer shell should have a deep "chill" or induction-hardened layer. This prevents the roller from "flat-spotting" when it hits rocks.

- Forged vs. Cast: Forged roller shells are generally stronger and less prone to internal defects than cast ones. We prefer forging for high-impact applications.

- End Caps: Look for secure, heavy-duty end caps that protect the seal area from "wire wrap" or debris buildup.

Roller Specifications Comparison

| Feature | Standard Duty Roller | Dingtai Heavy Duty Roller |

|---|---|---|

| Seal Type | Standard Rubber | Precision Duo-Cone |

| Material | Cast Steel | Forged 40Mn2 / 50Mn |

| Hardness Depth | 5-8mm | 10-12mm |

| Inspection | Batch Sampling | 100% Pressure Tested |

When I am at a factory, I always check the pressure testing 7 station. Every single roller we produce at Dingtai undergoes a vacuum or pressure test to ensure the seals are perfect before the oil is injected. This is the only way to guarantee that a roller won't leak the moment it hits the field. For a procurement manager, this level of quality control is the difference between a satisfied customer and a costly warranty claim.

What role do induction-hardened sprocket segments play in maintaining my Cat's drive efficiency?

The sprocket is where the power meets the pavement—or the mud. I always tell my team that the sprocket and the track chain are like a gear and a belt; if they don't match, nothing works efficiently. If your sprocket teeth are worn to a point, they are literally eating away at your track bushings.

Induction-hardened sprocket segments provide the necessary surface hardness to resist the abrasive wear caused by the track chain bushings. By maintaining their original tooth profile, they ensure smooth power transfer and prevent the chain from "jumping" or "popping," which can damage the final drive.

Sprocket segments 8 for Cat dozers are usually sold as "segments" (usually 3 to 5 teeth per segment). This makes them easier to replace without removing the entire track frame. The secret to a long-lasting sprocket is the heat treatment. If the teeth are too soft, they wear down quickly. If they are too hard all the way through, they become brittle and can snap off when hitting a hard rock.

The Importance of "Case Depth"

We use a process called induction hardening 9. This allows us to harden only the outer "skin" of the sprocket teeth to a specific depth (usually around 8-10mm). The core of the tooth remains relatively soft and flexible. This combination is perfect: a hard exterior for wear resistance and a tough interior for impact resistance.

Impact of Worn Sprockets on the System

- Fuel Efficiency: When teeth are worn, the machine loses grip on the chain, leading to slippage and higher fuel consumption.

- Vibration: Mismatched teeth and bushings create massive vibrations that travel through the final drive and into the cabin.

- Component Longevity: A worn sprocket will ruin a brand-new track chain in half its expected lifespan.

I always recommend replacing sprocket segments whenever you install a new track chain. It is a small investment that protects the most expensive part of your undercarriage. In my 20 years of experience, skipping this step is the most common mistake I see in the field.

How can I tell if my Cat-compatible idler assemblies use premium duo-cone seals for leak protection?

The idler's job is to guide the track and handle the tension from the recoil spring. It doesn't drive the machine, but it takes all the "shock" when the machine hits an obstacle. I’ve seen idlers crack or leak after just a few weeks because they weren't built for the impact of real-world job sites.

You can identify a premium idler by checking the manufacturer's technical data for "Duo-Cone" seal specifications and the use of "Heavy-Duty" shafts. A quality idler will also feature a cast or forged body with a reinforced center rib to prevent the side walls from spreading under heavy loads.

The idler assembly 10 is a large, heavy component that stays at the front of the track frame. It must rotate freely to keep the track aligned. If the idler develops a "flat spot" because it stopped turning, the machine will vibrate uncontrollably. This usually happens because of—you guessed it—seal failure.

Comparing Idler Construction Methods

| Feature | Cast Idler | Forged Idler |

|---|---|---|

| Strength | Good for general construction | Superior for mining/rocky ground |

| Weight | Standard | Generally heavier/denser |

| Cost | More economical | Higher initial investment |

| Durability | High | Maximum |

At Dingtai, we produce both cast and forged idlers. For machines working in sand or soft soil, a high-quality cast idler is usually sufficient. However, for David’s clients in the mining sector, I always suggest forged idlers. The forging process eliminates internal air bubbles and creates a grain structure in the metal that is much better at absorbing the "shocks" of a 50-ton dozer hitting a boulder.

Maintaining Proper Tension

The idler works closely with the track adjuster (the grease-filled cylinder). If your idler is high quality but your tension is wrong, you will still see fast wear. I tell my customers to always check their track sag. A track that is too tight is just as bad as a track that is too loose. It puts massive pressure on the idler bearings and the duo-cone seals, leading to the very leaks we are trying to prevent.

Conclusion

Choosing the right Cat undercarriage parts—chains, shoes, rollers, idlers, and sprockets—is about more than just finding a low price. It is about matching the quality of the components to the demands of your job site. By focusing on seal integrity, heat treatment, and material strength, you can significantly lower your cost per hour and keep your machines running longer.

Footnotes

1. Effective inventory management strategies for heavy equipment maintenance. ↩︎

2. Discussion on the benefits and maintenance of sealed and lubricated tracks. ↩︎

3. Technical overview of heavy machinery track centerline components and assemblies. ↩︎

4. Scientific properties and industrial applications of deep-hardened steel alloys. ↩︎

5. Geological characteristics of laterite soil and its abrasive effect on machinery. ↩︎

6. Database for technical specifications and performance of heavy equipment rollers. ↩︎

7. Standard procedures for industrial pressure testing of mechanical seals and components. ↩︎

8. Historical and technical wiki regarding heavy equipment sprocket design and evolution. ↩︎

9. Explanation of how induction heating improves surface hardness in industrial parts. ↩︎

10. Community insights on troubleshooting and maintaining idler assemblies for dozers. ↩︎