Dealing with undercarriage wear is a constant headache that eats into my profits. I often find myself staring at a worn-out track, wondering if I could have prevented this costly downtime with better parts.

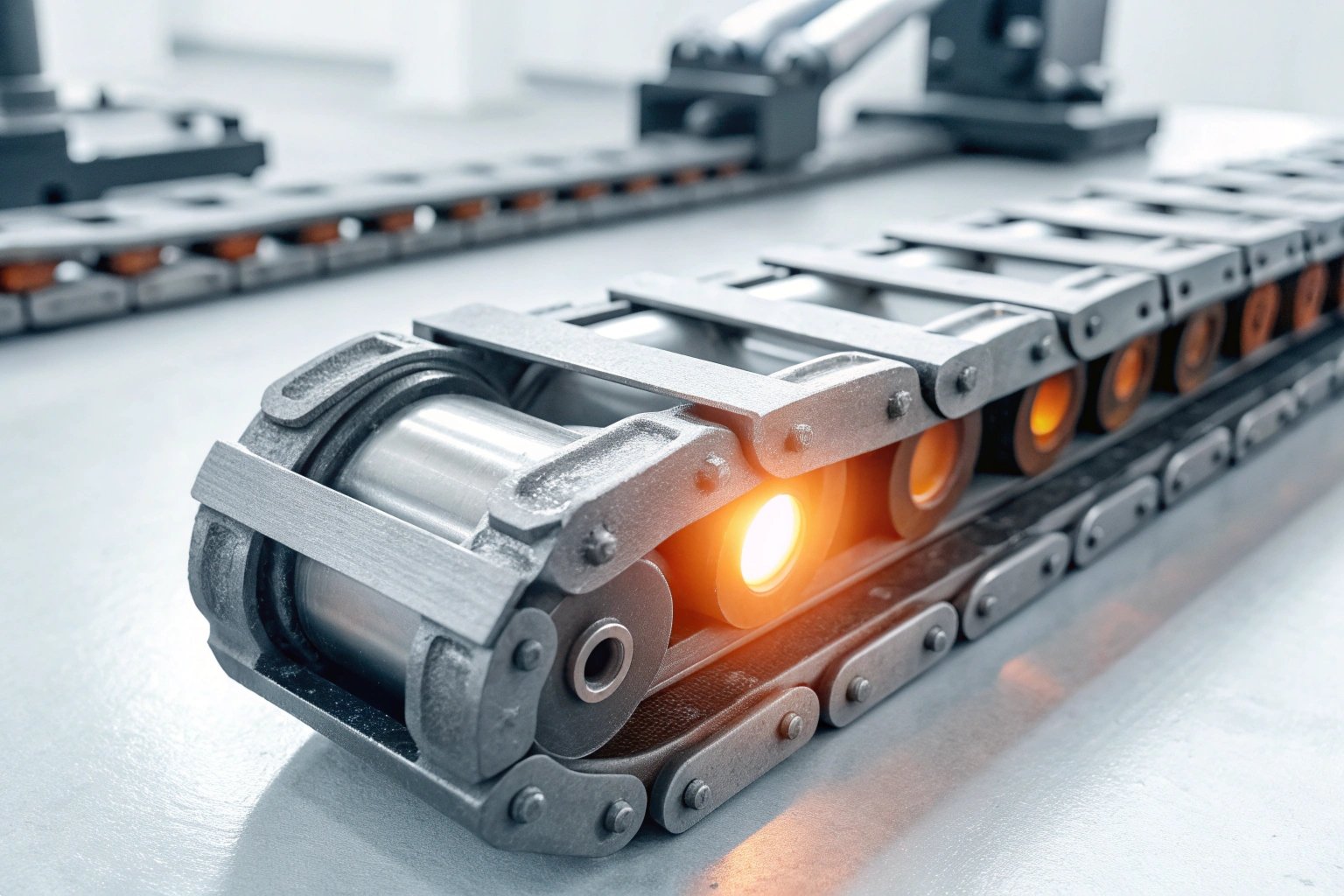

The five essential Cat dozer undercarriage parts are track chains, track shoes, rollers (bottom and carrier), idlers, and drive sprockets. These components work together to support the machine's weight and provide the traction needed for heavy-duty earthmoving and grading tasks.

The undercarriage 1 represents nearly half of a dozer's maintenance cost over its lifetime. Making the right choice on these five parts is not just about repairs; it is about protecting your bottom line and ensuring your machine stays in the dirt where it belongs.

How does the case-hardening depth of my Cat dozer's track links impact my total operating costs?

I have learned the hard way that not all track links are built the same. When I look at a link, I don't just see metal; I see a complex heat-treatment process that determines how many hours I get before the next replacement.

Case-hardening depth directly dictates the wearable life of the track link before the core metal is exposed. Deeper hardening allows the link to resist surface abrasion longer, significantly extending the interval between costly undercarriage overhauls and lowering the hourly operating cost.

Deep case hardening is the secret sauce for any long-lasting undercarriage. When we talk about "case depth," we are referring to the thickness of the outer layer of the steel that has been carbonized and quenched to a high Rockwell hardness 2. For a Cat dozer, which often operates in abrasive sand 3 or jagged rock, this layer is the only thing standing between a productive machine and a snapped chain. If the hardening is too shallow, the link wears down to the soft core quickly. Once that happens, the wear rate accelerates exponentially, and you will find your track tension constantly dropping.

From my experience in the manufacturing side at Dingtai, we focus heavily on the induction hardening process 4. We ensure that the hardness penetrates deep enough to allow for "run-to-destruction" or "wet-turn" scenarios. If you buy cheap links with poor heat treatment, you might save 20% upfront, but you will lose 50% of the service life. This means you are paying for labor and shipping twice as often. In the B2B world, especially for distributors like David Miller, consistency across batches is what keeps customers loyal.

Comparison of Track Link Hardening Processes

| Feature | Standard Induction Hardening | Deep Case Hardening (Dingtai Spec) | Through-Hardening |

|---|---|---|---|

| Surface Hardness | HRC 50-52 | HRC 55-58 | HRC 45-50 |

| Hardness Depth | 3mm - 5mm | 8mm - 12mm | Full Cross-section |

| Impact Resistance | Moderate | High | Excellent |

| Wear Life | Baseline | 1.5x Baseline | Variable |

| Best Application | Light Duty | Abrasive/Heavy Rock | High Impact |

When evaluating links, you should always ask for the heat treatment charts 5. A quality manufacturer will have no problem showing you the "S-curve" of their hardening depth. This transparency is what separates a professional factory from a backyard workshop. We use 35MnB or 40Mn2 steel because these alloys respond best to our quenching process, ensuring the links don't crack under the massive weight of a D8 or D10 dozer.

Why are "SALT" (Sealed and Lubricated Track) chains the industry standard for my Cat dozer?

I remember the days of dry tracks and the constant "screech" they made. It was the sound of metal grinding away metal, and it meant my pins and bushings were dying a slow, painful death.

SALT chains utilize internal lubrication and high-performance seals to eliminate internal friction between the pin and bushing. This technology prevents "track stretch" caused by internal wear, doubling the life of the internal components compared to traditional dry or sealed-only tracks.

The transition to SALT (Sealed and Lubricated Track) changed everything for heavy equipment maintenance. In a standard track, dirt and grit find their way into the space between the pin and the bushing. This acts like sandpaper, grinding down the metal from the inside out. This is why tracks seem to "stretch"—it isn't the metal growing; it is the joints becoming loose due to wear. With SALT, we inject a specialized synthetic oil 6 into the reservoir inside the pin. This oil is held in by a complex seal group that keeps the lubricant in and the contaminants out.

Critically, the seals are the most important part of this assembly. If a seal fails, the oil leaks out, and the joint becomes a "dry" joint. This leads to localized heating and rapid failure. That is why at Dingtai, we use premium seal groups 7 that can withstand extreme temperatures and pressure. For a buyer like David Miller, the reliability of these seals is the difference between a happy end-user and a massive warranty claim. We test 100% of our SALT chains for vacuum leaks before they leave the factory to ensure every joint is perfectly sealed.

SALT vs. Dry Track Performance

| Metric | Dry Track (Sealed) | SALT (Lubricated) |

|---|---|---|

| Internal Wear | High (Metal on Metal) | Near Zero (Oil Film) |

| Noise Level | Loud / Squeaking | Quiet / Smooth |

| Heat Generation | Significant | Minimal |

| Service Interval | Short (Frequent Turns) | Long (Extended Life) |

| Total Cost of Ownership | Higher due to replacement | Lower over life of machine |

Furthermore, using SALT chains reduces the load on the drive motor 8 and final drive. Because the joints flex with less resistance, the machine uses less fuel to move. It’s a win-win for the owner-operator. When I'm advising clients on large-scale fleet maintenance, I always point out that the slightly higher initial cost of SALT is recovered within the first 1,000 hours of operation through reduced fuel consumption and eliminated "pin and bushing" turns.

How can I verify that my Cat dozer's drive sprockets are forged for maximum impact resistance?

Nothing stops a job faster than a snapped sprocket tooth. I've seen drive wheels crumble like cookies because the casting had internal air bubbles that no one caught at the factory.

Forged drive sprockets are superior to cast ones because the forging process aligns the grain flow of the steel with the shape of the tooth. You can verify quality by checking for a uniform surface finish, absence of casting parting lines, and requesting ultrasonic test reports to confirm internal density.

The drive sprocket is the "engine" of the undercarriage. It takes all the torque from the final drive and pushes it into the track. If the sprocket fails, the machine is a multi-ton paperweight. Forging is the gold standard here. During forging, the metal is hammered into shape, which compacts the molecules and creates a much stronger structure than simply pouring molten metal into a mold. A forged sprocket tooth 9 can take the "shock" of hitting a buried boulder without snapping off.

In my factory, we use high-tonnage forging presses to ensure the sprocket segments for Cat dozers meet or exceed OEM standards. We then use CNC machining to ensure the tooth profile is perfect. If the tooth shape is even slightly off, it won't engage the bushing correctly, leading to "hopping" or premature wear on the expensive track chain. For David Miller’s customers, this precision means the parts "just fit" without the need for grinding or forcing, which saves hours in the shop.

Material Specifications for Sprockets

| Component | Common Material | Process | Heat Treatment |

|---|---|---|---|

| Sprocket Segment | 35MnB | Forged | Surface Quenching |

| Bolt Holes | Grade 12.9 | Drilled & Reamed | Tempered |

| Tooth Profile | Alloy Steel | CNC Machined | Induction Hardened |

Checking the hardness of the teeth is also vital. We target a surface hardness of HRC 50-55. If it's too hard, the teeth become brittle and chip. If it's too soft, they wear down flat in a few hundred hours. It is a delicate balance. I always tell my clients to look at the "wear pattern" on their old sprockets. If the wear is uneven, the alignment was wrong. If the teeth are pitted, the material quality was poor. Buying from a direct manufacturer like Dingtai ensures you get the metallurgical reports to back up the visual quality.

What makes a high-quality recoil spring assembly vital for my Cat dozer's structural integrity?

I used to think the spring was just there for tension, but after seeing a track frame crack from a simple impact, I realized it’s actually the machine's primary shock absorber.

A high-quality recoil spring assembly protects the track frame and final drive by absorbing massive impact loads when the idler hits an obstacle. It must have a precisely calibrated spring rate and a heavy-duty hydraulic adjuster to maintain constant track tension and prevent structural fatigue.

The recoil spring assembly 10 and track adjuster assembly is the unsung hero of the undercarriage. When a dozer is working in "the rough," the front idler is constantly hitting rocks and stumps. Without a functional recoil spring, every one of those hits would be transmitted directly into the rigid track frame and the sensitive bearings of the final drive. A "frozen" spring or a leaking hydraulic adjuster is a recipe for a broken frame, which is often a "total loss" repair for older dozers.

We manufacture these assemblies using high-tensile chrome-silicon steel for the springs to ensure they don't lose their "bounce" over years of service. The hydraulic cylinder, which you pump with grease to tension the track, must have perfect seals. If it leaks, your track goes slack, and you'll throw a chain within minutes of starting work. This is a major pain point for David Miller’s clients—unreliable adjusters mean constant manual labor to re-tension tracks, wasting valuable daylight.

We also focus on the safety aspect of these assemblies. Recoil springs are under thousands of pounds of pressure. A poorly made assembly can be a literal bomb if it fails during maintenance. That is why we use heavy-wall tubing and reinforced end-caps. When I talk to procurement managers, I emphasize that these aren't just parts; they are safety-critical components. We provide full technical support to ensure they are installed correctly and maintained safely.

Conclusion

Understanding these five essential parts—track chains, shoes, rollers, idlers, and sprockets—is the first step toward reducing your Cat dozer’s operating costs. High-quality manufacturing and proper maintenance are key to longevity.

Footnotes

1. Explore community discussions on maintaining and troubleshooting heavy equipment undercarriages. ↩︎

2. Guide to understanding the Rockwell scale for measuring metal hardness and durability. ↩︎

3. Geological insights into how different types of sand and soil cause abrasion on machinery. ↩︎

4. Technical explanation of how induction heating strengthens steel for industrial applications. ↩︎

5. Reference for professional metallurgical standards and heat treatment processes for steel parts. ↩︎

6. Information on synthetic lubricants designed for heavy-duty industrial and construction equipment. ↩︎

7. Details on high-performance sealing solutions for extreme engineering environments. ↩︎

8. Overview of hydraulic and electric drive systems used in heavy earthmoving machinery. ↩︎

9. Learn about the mechanical advantages of forging for high-stress drivetrain components. ↩︎

10. Comprehensive wiki regarding the components and functions of heavy construction equipment. ↩︎