Choosing between excavator undercarriage parts manufacturers feels overwhelming, but the right partner can double your parts' lifespan and slash downtime. This guide moves beyond surface-level price comparisons to reveal the critical, often-hidden technical details. You'll learn how to identify a top-tier supplier by assessing factors like machining tolerance—where a 0.1mm error can cause failure—and advanced heat treatment techniques that separate the best from the rest.

Last Updated: January 2025 | Estimated Reading Time: 9 Minutes

This Article Will Answer for You

- What's at Stake: Why the right manufacturer choice is critical for your bottom line.

- OEM vs. Aftermarket: How to decide which supplier type fits your needs.

- The 7-Step Vetting Framework: A foolproof method to identify a top-tier manufacturer.

- Key Questions: What to ask about materials and heat treatment to expose quality.

- Beyond the Price Tag: How to calculate the True Cost of Ownership (TCO) accurately.

- Remote Verification: How to confirm a manufacturer's capabilities from afar.

- Final Steps: What crucial checks to make before placing your bulk order.

What's at Stake? Why Your Choice of Undercarriage Manufacturer Matters More Than You Think

A single failed roller doesn't just halt a job; it can trigger a cascade of expensive repairs across the entire system. Your choice of excavator undercarriage parts manufacturers directly impacts your operational costs, safety, and reputation. A poorly made part can lead to catastrophic failure, causing unexpected downtime that costs thousands per day and potentially damaging more expensive components like the final drive or the track chain itself.

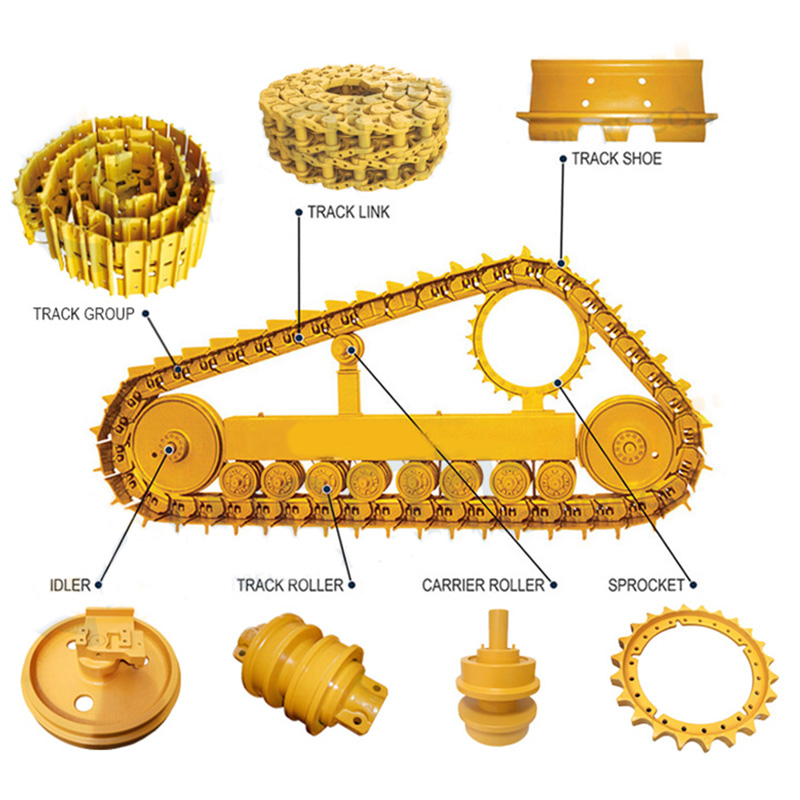

Think of an undercarriage not as a collection of individual parts, but as an interdependent system. According to industry failure analysis, a worn sprocket will destroy a brand-new track chain in less than 50% of its expected life. This is because the pitch (the distance between pins) no longer matches perfectly, creating excessive friction and stress. Choosing a manufacturer that guarantees system-wide compatibility and quality isn't just a preference; it's a fundamental strategy to protect your investment and ensure your fleet stays productive.

OEM vs. High-Quality Aftermarket: Which Type of Manufacturer is Right for Your Fleet's Bottom Line?

The debate isn't about OEM vs. Aftermarket; it's about separating top-tier aftermarket suppliers from low-quality imitators. While OEM parts offer a guarantee of fit, they come at a premium price. A high-quality aftermarket manufacturer, especially one that also provides OEM services, can deliver parts that meet or even exceed original specifications at a significantly better price point. The risk lies with generic, unvetted aftermarket suppliers.

The key differentiator is process control. Leading aftermarket suppliers invest heavily in their own heat treatment facilities, CNC machining centers, and quality control labs. This allows them to reverse-engineer and improve upon OEM designs, for instance, by using superior seal technology or a more advanced steel alloy for specific, high-abrasion environments like those with granite rock. For fleets like those using Caterpillar or Hitachi undercarriage parts, partnering with a proven aftermarket manufacturer offers the best of both worlds: OEM-level reliability and a healthier bottom line.

Practical Tips and Recommendations for Users

- For Critical, High-Uptime Fleets: Prioritize manufacturers with documented OEM supply experience. Their processes are already audited and approved to the highest standards.

- For Budget-Conscious Fleet Managers: Use the 7-step vetting framework below to qualify a high-quality aftermarket supplier. Ask for performance data and case studies in applications similar to yours.

- For Mixed Fleets: Partner with a manufacturer that has a wide product range compatible with brands like Komatsu, Hyundai, and John Deere to streamline your procurement and ensure consistent quality.

The 7-Step Vetting Framework: How Can You Identify a Top-Tier Manufacturer and Avoid Costly Mistakes?

Identifying a reliable manufacturer requires looking beyond the sales brochure and focusing on their core production capabilities. This 7-step framework will help you systematically evaluate any potential supplier of undercarriage parts for excavators and bulldozers, ensuring you partner with a factory that values quality over shortcuts. This process is exactly what experienced OEM procurement managers use to secure their supply chains.

The Vetting Checklist

- Verify In-House Critical Processes: Does the manufacturer perform heat treatment, forging, and crucial machining in-house? Outsourcing these steps introduces massive quality variations.

- Demand Machining Tolerance Reports: Ask for CMM (Coordinate Measuring Machine) inspection reports for parts like rollers and idlers. A tolerance of ±0.02mm is OEM-grade; ±0.2mm is a red flag for premature failure.

- Scrutinize Seal Technology: The #1 cause of roller failure is lubricant loss from a bad seal. Ask if they use duo-cone or multi-lip floating seals and if they perform mud-slurry testing.

- Analyze Material Composition & Traceability: Request material certificates (MTRs) for a recent batch. A serious supplier can trace the steel composition of every part back to the original heat lot.

- Audit Certifications & PPAP Capabilities: Don't just accept an ISO 9001 certificate. Ask for their latest audit report and if they can provide a PPAP (Production Part Approval Process) package. This is standard for any OEM supplier.

- Evaluate R&D and Customization: Can they discuss how they would modify a part for your specific climate (arctic vs. desert) or soil conditions (sandy vs. clay)? This demonstrates true engineering depth.

- Conduct a Thorough Sample & Pilot Order Test: Don't just look at a sample. Have it dimensionally inspected and hardness tested. A small pilot order on one machine is the ultimate test before a bulk commitment.

Real-World Case Study: A large mining contractor in Australia switched to a vetted aftermarket supplier for their Hitachi undercarriage needs. By insisting on a supplier with in-house, dual-stage induction hardening, they extended their track roller life from 2,800 hours to over 4,500 hours in highly abrasive iron ore, saving over $200,000 annually in downtime and parts.

What Key Questions About Materials and Heat Treatment Should You Ask Every Potential Supplier?

The right questions can quickly reveal whether a manufacturer is a true expert or just a reseller. Instead of asking "Is your steel good?", which gets a "yes" from everyone, ask specific, technical questions about their processes. A quality manufacturer's engineering team will be happy to discuss these details, while a low-tier supplier will likely be unable to answer.

Focus your questions on hardness depth and uniformity, which are far more important than a simple surface hardness number. For example, a track link needs "through-hardening" to resist stretching and cracking under load, while a roller needs a very hard outer case with a softer, tougher core to absorb impacts without shattering. True excavator undercarriage parts manufacturers master these nuances; others simply don't.

Questions That Expose Quality Gaps

| Topic | A Bad Question to Ask | A Great Question to Ask | What the Answer Tells You |

|---|---|---|---|

| Heat Treatment | "How hard are your rollers?" | "What is your effective case hardness depth on track rollers, and how do you ensure a gradual hardness gradient to the core?" | Reveals if they use advanced methods like induction hardening vs. simple flame hardening, which prevents spalling (chipping). |

| Steel Alloy | "Do you use boron steel?" | "What micro-alloying elements (like Chromium or Molybdenum) do you add to your 35MnB steel for track links, and why?" | Shows if they customize materials for strength and wear resistance, or just use a generic "off-the-shelf" steel grade. |

| Large Parts | "Is your sprocket strong?" | "How do you control heat uniformity during the quenching of large-diameter sprockets to prevent soft spots?" | Indicates if they use advanced technology like rotary induction or continuous furnaces, crucial for preventing localized, rapid wear. |

Beyond the Price Tag: How Do You Accurately Calculate the True Cost of Ownership (TCO) for Undercarriage Parts?

The cheapest part is almost always the most expensive one in the long run. The initial purchase price of an undercarriage component is often less than 20% of its True Cost of Ownership (TCO). A comprehensive TCO calculation must include the costs of downtime, labor for replacement, and the accelerated wear on adjacent parts.

To calculate TCO, use this simple formula: **TCO = (Initial Price + Installation Cost) / Service Hours**. A $150 roller that lasts 2,000 hours has a TCO of $0.075 per hour (plus labor). A "cheaper" $100 roller that fails at 800 hours due to a bad seal has a TCO of $0.125 per hour—66% more expensive, not including the cost of lost production and the extra mechanic's time. When you present it this way, the value of sourcing from reputable excavator undercarriage parts manufacturers becomes undeniable.

How Can You Effectively Verify a Manufacturer's Certifications and Production Capabilities from Afar?

In today's global market, you don't need to be on-site to conduct a thorough audit. With modern technology, you can effectively vet a manufacturer from anywhere in the world. Don't just take a PDF of a certificate at face value. A serious and transparent partner will be willing to prove their capabilities.

Remote Verification Checklist:

- Live Video Factory Tour: Ask your sales contact for a live, unedited video call where they walk you through the key production areas: the forging line, the heat treatment furnaces, the CNC machining workshop, and the final assembly and testing area.

- Verify Certifications Online: Use the certificate number on an ISO 9001 or SGS certificate and verify it on the issuing body's official website. This confirms it's not an expired or fake document.

- Request Redacted OEM Documents: Ask for a (redacted) example of a quality document they've prepared for another OEM client, such as a PPAP report or a process FMEA (Failure Mode and Effects Analysis). This proves they operate at that level.

- Check Third-Party Platforms: Look for the supplier on B2B platforms that offer their own factory audits and verification reports. These can provide an unbiased third-party perspective.

From Samples to Shipping: What Are the Crucial Final Steps Before Placing Your Bulk Order?

The final checks you make before signing a purchase order are your last line of defense against quality issues. The sample you receive isn't just a paperweight; it's a critical piece of evidence. At the same time, clarify all logistical details to prevent costly surprises when your shipment arrives. This ensures that the quality you approved is the quality you receive in your bulk order of undercarriage spare parts for excavators.

Your goal is to confirm that the manufacturer can not only produce a perfect "golden sample" but can also replicate that quality at scale and deliver it safely to your facility. Discuss packaging in detail—properly crated and protected parts prevent damage during transit, which can be just as costly as a manufacturing defect. Clear communication on lead times and shipping terms is also non-negotiable.

Final Pre-Order Checklist

- Destructive and Non-Destructive Sample Testing: Send your sample to an independent lab to verify its material composition, core hardness, and case depth. This objective data is worth far more than a visual inspection.

- Packaging Confirmation: Ask for photos or a specification sheet of how your parts will be packed. Are rollers individually protected? Are track groups assembled and secured on a robust steel pallet?

- Incoterms and Lead Time Agreement: Confirm the shipping terms (e.g., FOB, CIF) and get a written confirmation of the production lead time. Ask about their process for communicating potential delays.

Frequently Asked Questions (FAQ)

What's the biggest difference between OEM and high-quality aftermarket undercarriage parts?

The primary difference lies in process control and material customization. While both use similar base materials, top-tier aftermarket manufacturers like Dingtai often match or exceed OEM specs in heat treatment and machining tolerances to win business. They also offer more flexibility for terrain-specific adaptations, providing a better Total Cost of Ownership.

How long should excavator undercarriage parts last?

There's no single answer, as lifespan depends on the machine, application, operator, and terrain. However, a high-quality undercarriage system should provide 3,000 to 5,000+ operating hours. Premature failure (under 1,500 hours) almost always points to issues with a supplier's manufacturing process, such as poor seal technology or incorrect heat treatment.

Can I mix and match undercarriage parts from different manufacturers?

It's highly discouraged. An undercarriage is a system of interlocking wear components. A new chain on a worn sprocket, or vice versa, will cause accelerated wear on both parts. For optimal life and performance, it's best to source a complete system from a single, reliable excavator undercarriage parts manufacturer to ensure perfect pitch and tolerance matching.

Conclusion and Key Takeaways

Vetting excavator undercarriage parts manufacturers is about digging deeper than the price. The most reliable suppliers distinguish themselves through superior process control, particularly in heat treatment, machining tolerances, and seal technology. By using the 7-step vetting framework, asking targeted technical questions, and calculating the True Cost of Ownership, you can confidently move beyond risky, low-cost options and build a partnership that enhances your fleet's reliability and profitability.

Your next step is to put this knowledge into action. Start by shortlisting 2-3 potential manufacturers and apply the remote verification checklist. Request a sample and invest in independent testing. This upfront due diligence is the single best investment you can make to guarantee long-term performance and avoid costly field failures. Ready to partner with a manufacturer that passes every test? Contact the Dingtai team today.

About Quanzhou City Dingtai Engineering Machinery Co., Ltd.

With over 20 years of specialized experience, Quanzhou Dingtai is a leading manufacturer of undercarriage parts for bulldozers and excavators. We control all critical manufacturing processes in-house at our ISO 9001 and SGS-certified facility, from forging and heat treatment to final assembly. This allows us to provide OEM services to world-renowned brands and deliver aftermarket parts that consistently exceed industry standards for performance and longevity.

Discover the Dingtai difference. Request a technical consultation or get a quote for your fleet today.

Last Updated: January 2025