Choosing the right Komatsu track shoe assembly parts is one of the most critical decisions you'll make for your machine's uptime and operational cost. A quality assembly can deliver over 8,000 hours of performance, while a poor choice can fail in under 2,000. This guide gives you the expert knowledge to select parts that maximize your investment, reduce downtime, and keep your projects on schedule.

Last Updated: October 2025 | Estimated Read Time: 9 Minutes

This Article Will Answer

- What is a Komatsu Track Shoe Assembly and Why is it Critical?

- How to Find the Correct Part Number for Your Komatsu Machine

- Komatsu OEM vs. Aftermarket: Which Offers Better Value?

- How to Choose the Right Track Shoe for Your Ground Conditions

- What Key Components Are Included in a Complete Assembly?

- What Are the Common Signs of Wear You Can't Ignore?

- Is There a Step-by-Step Guide for Installing Track Shoes?

- Where to Source Reliable Komatsu Track Shoe Parts with a Warranty

What is a Komatsu Track Shoe Assembly and Why is it Critical for Machine Uptime?

A Komatsu track shoe assembly is the complete system that connects your machine to the ground, transferring power into movement. It's far more than just a "track pad"; it's an engineered system of track shoes (plates), links, pins, bushings, and high-tensile bolts. The quality of this entire `track shoe assy` dictates your machine's traction, stability, and, most importantly, the wear life of the entire undercarriage, which can account for up to 50% of your machine's maintenance costs.

Think of the track shoe assembly as the tires on a heavy-duty truck. If the tread is wrong for the terrain or the rubber is poor quality, you lose performance and face a higher risk of costly failure. For a Komatsu excavator or bulldozer, a failing track assembly doesn't just mean a flat tire; it means project-stopping downtime. Choosing a robust `Komatsu track shoe assembly parts` supplier ensures every component works in harmony, preventing premature wear on expensive sprockets and rollers.

How Do I Find the Correct Part Number for My Komatsu Excavator or Bulldozer?

Finding the correct part number is the first step to avoiding costly ordering mistakes. The most reliable method is to use your machine's serial number, as Komatsu often uses different undercarriage configurations on the same model. For example, a PC360-11 may have different options depending on its intended application (e.g., standard vs. long crawler).

Practical Tips for Finding Your Part Number

- Check the Machine's ID Plate: The full model and serial number are stamped on a metal plate, usually on the cab frame or chassis. This is the most accurate information you can provide to a supplier.

- Inspect the Old Part: Komatsu often stamps or casts the part number directly onto the track shoe itself. Clean off the dirt and look for a series of numbers.

- Use Your Parts Manual: If you have the original parts manual for your machine's specific serial number, the correct track shoe assembly number will be listed there.

- Consult an Expert Supplier: A knowledgeable `Track Shoe Assembly Supplier` can use your serial number to cross-reference their database and guarantee a perfect fit.

Real-World Example: A contractor ordered track shoes for their Komatsu PC200 based on the model alone. The parts arrived but didn't fit because their machine had the "LC" (Long Crawler) option. Verifying with the serial number would have saved them a week of downtime and thousands in shipping costs.

To learn more about how undercarriage components work together, see our detailed guide on 《The Complete Undercarriage Parts System》.

Komatsu OEM vs. Aftermarket Track Shoes: Which Offers Better Value and Durability?

The "best" choice between OEM and aftermarket depends on balancing initial price with long-term performance and value. While Komatsu OEM parts guarantee a perfect fit and material quality, a top-tier aftermarket manufacturer can offer comparable or even superior performance at a significantly lower cost—often 20-40% less. The key is to avoid cheap, low-quality suppliers who cut corners on materials and heat treatment.

The difference lies in the details you can't see. Forging quality, the depth of heat treatment, and the precision of the bolt holes all determine how long the part lasts. A premium aftermarket `Track Shoe Assembly Manufacturer` uses high-carbon and boron-alloyed steel, just like OEMs, and implements rigorous quality control to ensure every part meets strict specifications. This is where the true value is found—OEM performance without the OEM price tag.

OEM vs. Aftermarket Comparison

| Feature | Komatsu OEM | High-Quality Aftermarket (e.g., Dingtai) | What it Means for You |

|---|---|---|---|

| Material | High-grade Boron Steel | High-grade Boron Steel (e.g., 25MnB) | Both offer excellent strength and wear resistance in tough conditions. |

| Heat Treatment | Deep, uniform hardening | Through-hardened to HRC 42-48 | Ensures wear resistance through the life of the shoe, not just on the surface. |

| Cost | Highest initial price | 20-40% lower initial price | Significant upfront savings with comparable or longer service life. |

| Warranty | Standard OEM warranty | Often a longer or more comprehensive warranty | Greater peace of mind and protection for your investment. |

Single, Double, or Triple Grouser: How to Choose the Right Track Shoe for Your Ground Conditions

The number of grousers (the protruding ribs on a track shoe) directly impacts your machine's traction, maneuverability, and ground disturbance. Choosing the wrong type can lead to poor performance, excessive ground damage, or accelerated undercarriage wear. It's a simple choice that has a massive impact on your daily operations.

Think of it this way: you wouldn't wear dress shoes to hike a mountain. Similarly, using a high-traction single grouser on finished asphalt will destroy the surface and wear out the shoe quickly. Your goal is to match the shoe to the majority of the ground conditions you work in. A good `Track Shoe Assembly Factory` will offer all three types to suit various applications.

Which Grouser Type is Right for You?

- Single Grouser: Provides the highest traction and penetration. Best for: Hard rock, quarries, and high-impact conditions where maximum grip is essential.

- Double Grouser: Offers a great balance of traction and low turning resistance. Best for: Mixed soil, dirt, and general construction work. It's the most common all-purpose choice.

- Triple Grouser: Delivers the lowest ground pressure and turning resistance, minimizing surface damage. Best for: Soft ground, swamps, asphalt, and finished surfaces where flotation is key.

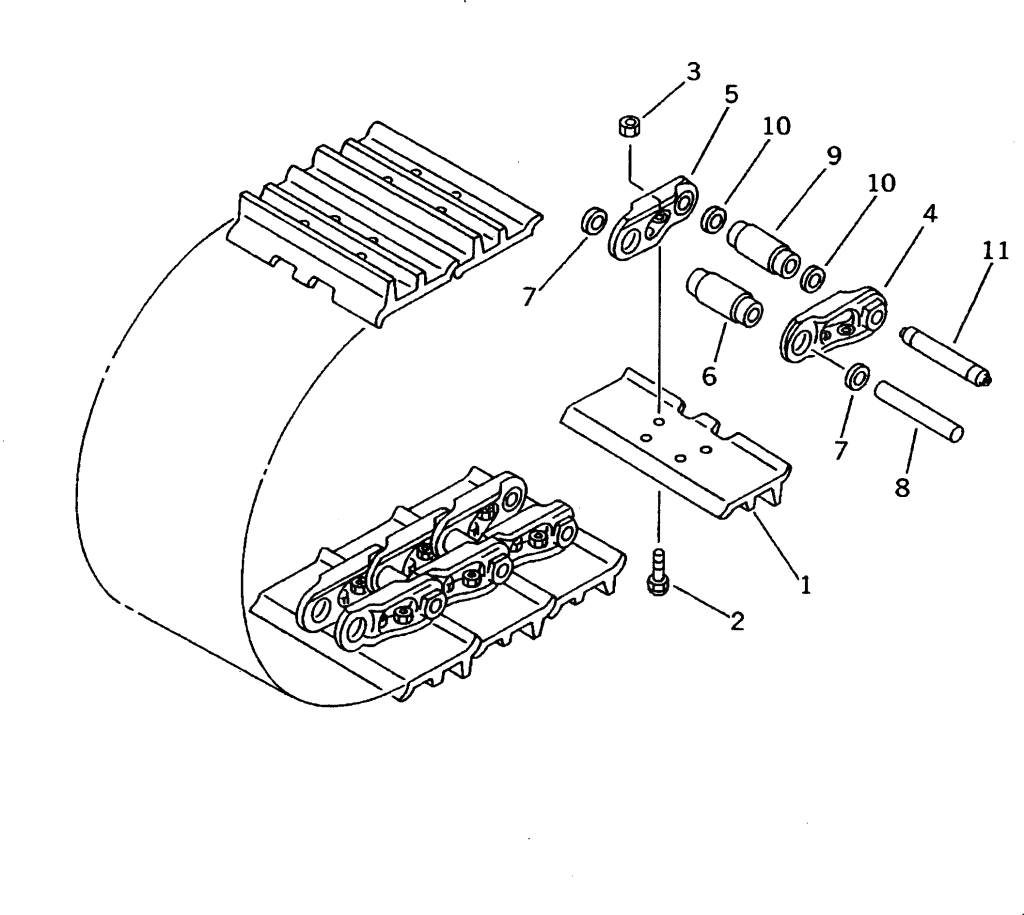

What Key Components are Included in a Complete Komatsu Track Shoe Assembly?

When you order a "track shoe assembly" or `track shoe assy`, you are getting more than just the plates. A complete assembly is a pre-built chain ready for installation, ensuring all components are new and matched for wear. This is critical because mixing old and new parts will cause accelerated, uneven wear.

A complete assembly from a reliable supplier includes:

- Track Shoes (Plates): The core component that contacts the ground, available in different grouser configurations.

- Track Links: The chain structure that holds the shoes together and engages with the sprocket.

- Track Pins & Bushings: These form the pivot points in the chain. Their wear determines the "stretch" or pitch elongation of the track.

- High-Tensile Bolts & Nuts: Specially designed hardware to secure the shoes to the links. Using incorrect bolts is a common cause of failure.

What are the Common Signs of Wear Indicating Your Track Shoes Need Replacement?

Proactively inspecting your undercarriage for signs of wear can save you from catastrophic failure and unplanned downtime. Don't wait until a track breaks on the job site. Regular visual checks can tell you everything you need to know. Look for these five key indicators during your daily walk-around.

- Grouser Wear: When the grousers are worn down to less than one inch (or look like a flat plate), your traction is severely compromised.

- "Stretched" Track: If you have to adjust your track tension frequently, it's a sign that the internal pins and bushings are worn out, causing the chain pitch to elongate.

- Scalloping: A wavy, uneven wear pattern on the surface of the track shoes indicates turning in one direction too often or a problem with roller alignment.

- Loose or Missing Bolts: This is a critical safety issue. Loose bolts cause the shoe holes to become elongated, eventually leading to shoe loss and damage to the links.

- Cracks: Any visible crack on the track shoe, especially around the bolt holes or at the base of the grousers, means the part has reached the end of its structural life and must be replaced immediately.

For more details on extending undercarriage life, read our guide on 《5 Tips to Maximize Undercarriage Longevity》.

Can You Provide a Step-by-Step Guide for Installing a Komatsu Track Shoe Assembly?

Proper installation is just as important as part quality for ensuring a long service life. While you should always consult your machine's official service manual, here is a simplified, high-level guide to the process. The most critical steps are releasing tension correctly and applying the proper torque to the bolts.

Disclaimer: This is an overview, not a replacement for professional guidance. Always follow OEM safety procedures.

- Safety First: Park the machine on a hard, level surface and chock the tracks.

- Release Track Tension: Locate the grease fitting on the track frame and slowly loosen the valve to release the tension. The track will become slack.

- Split the Track: Use a hydraulic master pin press to remove the master pin connecting the two ends of the track chain.

- Lay Out the New Assembly: Stretch the new `shoe track assembly` out in front of the old one.

- Connect and Align: Drive the machine forward slowly onto the new track assembly, guiding it around the idler and sprocket.

- Install the Master Pin: Reconnect the track using the master pin press.

- Adjust Tension: Tighten the grease fitting to adjust the track sag to the manufacturer's specification (usually found in the operator's manual). Proper tension is crucial for wear life.

Where Can You Source High-Quality, Reliable Komatsu Track Shoe Parts with a Warranty?

The best source for `Komatsu track shoe assembly parts` is a specialized manufacturer with a proven track record, extensive quality control, and direct-to-market pricing. While OEM dealers are an option, a certified aftermarket supplier offers the ideal blend of quality, value, and availability. Look for a partner who can demonstrate their expertise and stand behind their product with a solid warranty.

A trusted `Track Shoe Assembly Manufacturer` will provide:

- Material Certifications: Proof that they use high-quality boron steel.

- ISO 9001 Certification: A guarantee of a consistent, quality-managed production process.

- OEM Experience: A history of supplying parts to major equipment brands is a strong indicator of quality and reliability.

- A Comprehensive Warranty: A manufacturer who believes in their product will offer a warranty of at least 2,000 hours.

2025 Trends in Undercarriage Technology

The world of undercarriage parts is constantly evolving. As a leader in the industry, we see several key trends shaping the future for 2025 and beyond. These innovations are focused on extending wear life, reducing maintenance, and improving operational efficiency. Staying aware of these trends helps you make smarter purchasing decisions for your fleet.

Latest Advancements at a Glance

- Advanced Metallurgy: The use of nano-structured and micro-alloyed steels is becoming more common, offering up to 20% more wear resistance than traditional boron steels in high-abrasion environments.

- Sealed and Lubricated Tracks (SALT): While not new, the sealing technology is improving dramatically, with new polyurethane seals that better resist hardening and cracking, extending pin and bushing life by over 30%.

- Predictive Maintenance Sensors: Some high-end undercarriages now feature embedded sensors that monitor wear rates in real-time and alert fleet managers when replacement is needed, eliminating guesswork.

Market insights show a clear shift towards total cost of ownership (TCO) over initial purchase price. Fleet managers in 2025 are increasingly choosing premium aftermarket parts that offer longer life and better warranties, even if the upfront cost is slightly higher than budget options. This data-driven approach is proving to reduce overall maintenance spending by 15-25% annually.

Frequently Asked Questions (FAQ)

How long should Komatsu track shoes last?

Service life varies greatly, from 2,000 to over 8,000 hours. Key factors include the quality of the `Komatsu track shoe assembly parts`, ground abrasiveness, and operator habits. High-quality parts in low-abrasion soil will always last the longest.

Can I just replace a few broken track shoes?

It's strongly discouraged. Mixing new and worn parts creates uneven load distribution, which will cause both the new and old components to fail prematurely. For best results and lowest long-term cost, always replace track shoes as a complete set.

What is the difference between a track shoe and a track pad?

The terms are often used interchangeably. "Track shoe" typically refers to the steel plate on a bulldozer or excavator, while "track pad" can also refer to the rubber pads that bolt onto steel shoes for use on paved surfaces.

Are wider track shoes always better?

No. While wider shoes offer better flotation on soft ground, they also increase stress and wear on undercarriage components during turning. Use the narrowest shoe that provides adequate flotation for your application.

Conclusion and Recommendations

Your machine's undercarriage is its foundation, and the Komatsu track shoe assembly parts are the most critical element of that foundation. Making an informed choice means understanding the difference between OEM and quality aftermarket, selecting the right grouser type for your job site, and recognizing early signs of wear. By investing in high-quality, certified parts from an experienced manufacturer, you can dramatically reduce your long-term operating costs and maximize machine uptime.

Ready to equip your fleet with undercarriage parts that deliver OEM performance and superior value? Your next step is to get a quote based on your machine's specific serial number and application. Contact a trusted specialist to ensure you get a guaranteed fit, a strong warranty, and parts that are built to last.

About Quanzhou Dingtai Engineering Machinery Co., Ltd

For over 20 years, we have been a leading `Track Shoe Assembly Manufacturer` and supplier of undercarriage parts for excavators and bulldozers. Our ISO9001 and SGS-certified factory produces parts for world-renowned brands, ensuring every component meets the highest standards for strength and durability. With a team of 20+ technical experts and 100% pre-shipment inspection, we deliver reliable parts that keep your machines moving.

Contact our team today for expert advice and a competitive quote on your next set of Komatsu undercarriage parts. Let us show you the Dingtai difference.

Last Updated: October 2025