My US clients, like David, need parts fast. Waiting for overseas shipping causes massive downtime. That’s why I’ve seen huge value in suppliers (like us) having a US partner.

Yes, there is a significant benefit. A supplier with a US partner can offer faster delivery from local inventory, reduced shipping costs, and quicker after-sales support. This local presence helps ensure parts meet US standards and reduces excavator downtime dramatically.

It sounds good, but as a purchasing director, you probably want details. How does this really work? Does it help with logistics? Does it just add a middleman? Let's break down what I've seen work based on my 20 years in this business.

Could a US-based partner help with logistics, warehousing, or after-sales support?

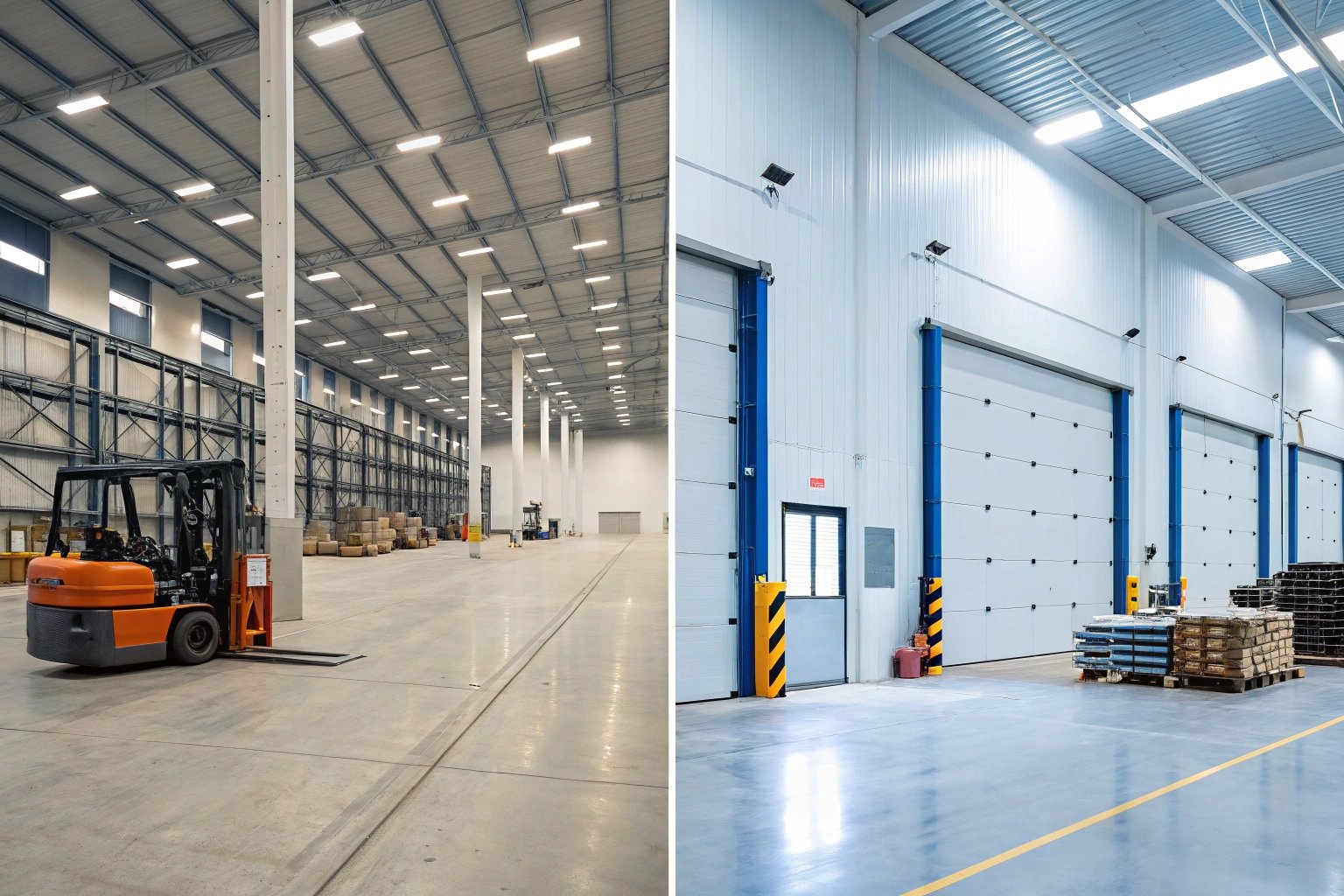

You order parts, but the container is stuck at the port. Your machine is dead in the water, and you have no answers. I've seen how a distribution center 1 completely solves this nightmare.

Absolutely. A US-based partner is key for logistics, warehousing, and after-sales. They can hold local stock, breaking down bulk shipments for rapid local delivery. They also provide immediate technical support and process warranty claims without international delays.

In my 20+ years at Dingtai, the biggest complaint I used to hear from my US distributors was lead time. A container takes weeks to cross the ocean. If a machine goes down, they can't wait weeks for a replacement sprocket or track chain. This is where the US partner model changes everything.

The Power of Local Warehousing

A factory in China, like ours, is built for mass production. We produce thousands of high-quality track rollers or drive sprockets at once. We ship these in 40-foot containers. A US partner, however, acts as our forward distribution hub.

We ship the container to their warehouse, not to 20 different small customers. The partner handles the complex import process, the customs clearance 2, the unloading, and the inventory management.

When a customer like David in the US needs five track chains for an urgent repair, he doesn't call me in China and wait 45 days. He calls the US partner. They pick the five chains from their shelf in a US-based warehouse. They ship it via LTL shipping 3, like UPS Freight. He gets them in 48 hours.

This model, which we use, turns a 6-week factory lead time into a 2-day domestic lead time for all our stocked items. It's the only way to truly support the urgent needs of the construction and mining industries.

How After-Sales Support Improves

This is a huge pain point for technical buyers. Let's imagine a track roller seal fails prematurely. A strategic aftermarket service 4 approach improves the entire experience.

- Without a US partner: The customer has to email me (Linda). I am in a different time zone. I have to ask my engineers. We might ask for the heavy, oily part to be shipped back to China for inspection. This is a logistical nightmare for the customer. The entire process can take a month.

- With a US partner: The customer calls the partner in the US. They are in the same time zone. They can provide immediate troubleshooting. They can authorize a replacement from their local stock immediately. Then, they deal with us (the factory) on the backend for the warranty credit.

The customer's problem is solved in days, not months. This builds immense trust and shows we stand behind our product.

Does it signal that the supplier is committed to and experienced with the US market?

You're tired of suppliers who don't understand US standards. Their parts don't fit, or the quality spec is wrong for your tough job sites. I find a US presence proves they've invested in your market.

Yes, a US partner is a strong signal of commitment. It shows the supplier has invested significant resources in understanding US regulations, quality standards, and customer expectations.

I talk to US buyers every day. Many, like my typical customer David, are technical experts. Setting up a US partnership is a physical and financial commitment to the US market.

Understanding US Standards (Not Just ISO)

The US market has specific demands. It's not just about having an ISO 9001 certification 5, which we have. It's about understanding the application.

For example, undercarriage parts used in the abrasive, sandy soil of a Florida construction site wear very differently than parts in the rocky quarries of Pennsylvania. A good US partner provides this ground-truth feedback. They'll call us and say, "David's customers in the Northeast region need a different heat treatment 6 on the track links to handle impact."

This feedback loop is impossible if we only sell direct from China via email. Because we have this partnership, our products are already adapted for the US market.

What This Signals to a Buyer

When a buyer sees we have an established US partner, it tells them several things:

- We are stable: We aren't going to disappear next month.

- We are confident: We know our quality is good enough to stock in the US.

- We are compliant: The partner ensures parts meet ASTM steel standards 7 and local material specs.

Could it potentially complicate my direct relationship with the factory?

You like talking directly to the factory. You worry a "partner" is just a middleman adding costs and confusion. I understand this completely. The type of partnership is what matters.

It can, if the relationship is not clearly defined. A poor partnership can add communication layers and increase costs. However, a true strategic partner acts as an extension of the factory.

The Right Model: The Strategic Partner

The right model, and the one we use, is a transparent partnership. Our US partner is an extension of our factory.

How does this work?

- Shared Systems: Our partner can see our production schedule. We can see their US inventory. It's a shared system.

- Clear Roles: The customer knows exactly who to call for what.

- Direct Technical Access: If the US partner's tech team can't solve a problem, they immediately set up a three-way call with my engineers in China.

How can I verify the nature of their relationship with their US partner?

A supplier says they have a US partner. But it might just be one guy in his garage, or a fake website. I tell my clients to ask these specific questions to cut through the noise.

Verify the relationship by asking both the supplier and the US partner specific questions. Ask for the partner's location and contact. Inquire about shared inventory systems.

1. Ask the Factory (The Supplier)

Start with the supplier salesperson. Be direct.

- "What is the legal name and address of your US partner?"

- "Is this partner an exclusive agent, a distributor, or a joint venture?"

2. Investigate the US Partner Directly

Next, contact the partner they named.

- Call their number. Do they answer the phone professionally?

- Check their LinkedIn company page 8. Do their profiles mention the factory's brand?

3. Look for Physical Evidence

- Google Maps 9: Look up the address they gave you. Is it a real warehouse or a residential house?

- Ask for a virtual tour 10 of the facility via video call to see the inventory on the shelves.

Conclusion

In my experience, a supplier with a real US partner isn't a middleman. They are a problem-solver, saving you time, money, and downtime.

Footnotes

1. Learn how distribution centers optimize the movement of goods in a supply chain. ↩︎

2. Official guide from CBP regarding the basics of importing into the United States. ↩︎

3. A comprehensive guide to Less-than-Truckload (LTL) shipping and domestic freight logistics. ↩︎

4. Research on how smart aftermarket services drive value for heavy equipment users. ↩︎

5. Overview of the international standard for quality management systems (QMS). ↩︎

6. Technical explanation of how heat treatment processes alter the properties of steel. ↩︎

7. Reference for ASTM standards governing the quality of steel materials used in construction. ↩︎

8. Use professional networking platforms to verify corporate partnerships and staff affiliations. ↩︎

9. Utilize mapping services to visually confirm the existence of physical warehouse locations. ↩︎

10. The importance of supply chain transparency for building trust in international manufacturing. ↩︎