Importing is a big risk. You worry about quality before placing a bulk order. I understand this fear. A trial order is the only way to be sure.

Yes, you absolutely can, and you absolutely should. As a manufacturer, I believe a trial order is essential. It is the standard, prudent way to verify our quality, materials, and specifications before you commit to a larger container order.

Placing that first sample order can feel complex. You probably have questions about the process, the cost, and the logistics. As a partner to businesses like yours, I want to make this transparent. Let's break down the common questions I hear from buyers.

What is the minimum quantity or value for my trial order?

You need to test quality, but you worry about high MOQs for a simple trial. You don't need a container, just a few parts. We designed our trial process to be flexible.

This is very flexible and depends on the part. For many of my partners, a trial order can be just 1 to 10 pieces. We are not trying to make a profit on samples; we are trying to build your trust for a long-term relationship.

The goal of a trial order isn't for us to make a large sale. The goal is to prove our manufacturing capability to you. As an experienced purchasing director, you know the difference between a supplier focused on a quick sale and a partner focused on a long-term supply chain. We are the latter.

How We Define a "Trial Order"

Clarity is important. In our business, we see three different types of "small" orders:

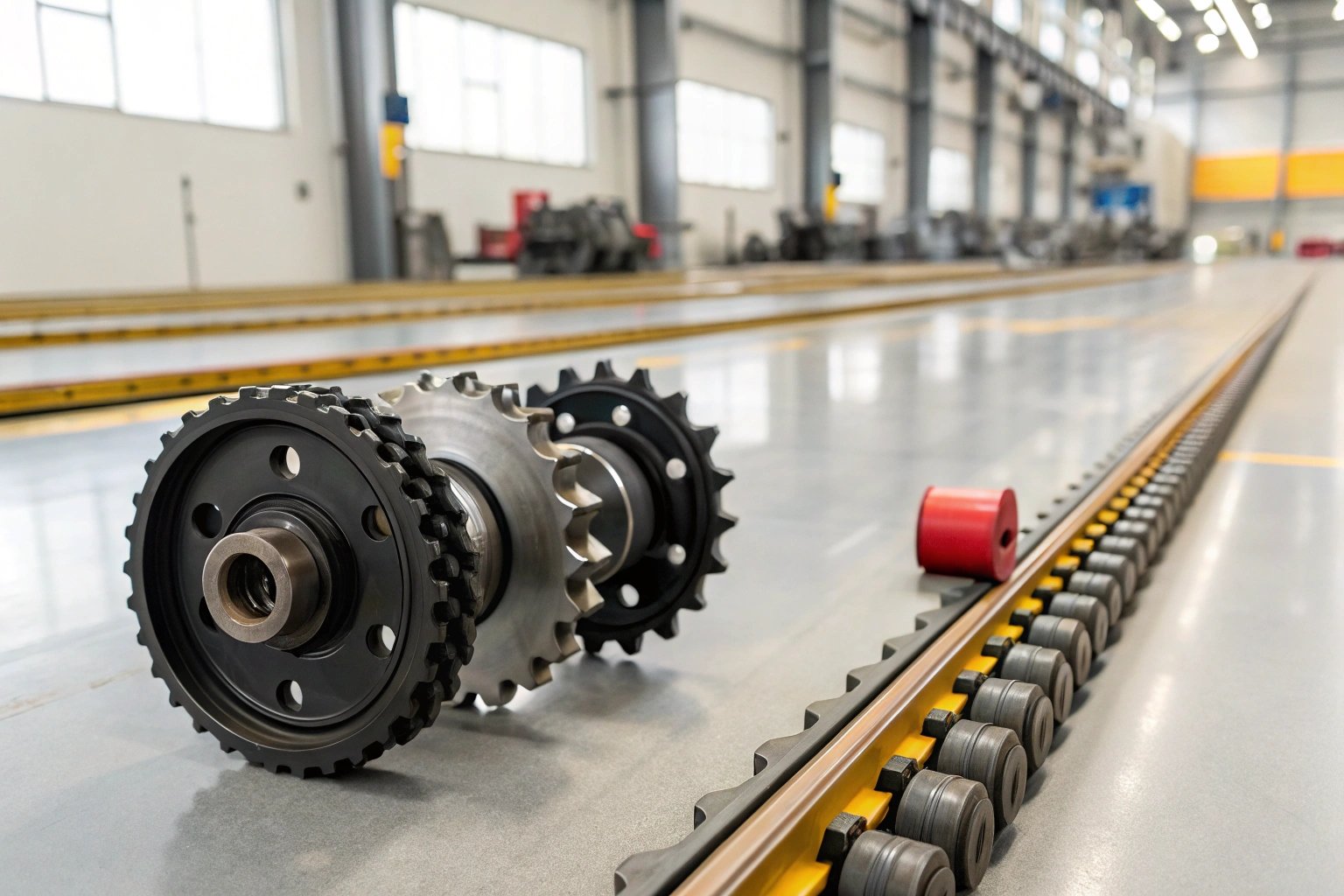

1. Stock Sample: This is usually one or two pieces of a standard item we keep in inventory, like a common track roller. The goal is just to see the physical product, the finish, and the branding.

2. Trial Order: This is a small, functional set. You might order 10 rollers and 2 idlers to equip one machine for a field test. This is the most valuable type of test.

3. Small Batch (LCL): This is less of a trial and more of a small commercial order, often shipped as Less than Container Load (LCL) 1.

For a true quality test, we recommend the "Trial Order." We are flexible on the quantity because we know you need enough parts to run a real-world test 2, which might mean 5 pieces, 10 pieces, or one full set.

Factors That Determine the Minimum Quantity

Your main concern is likely being forced to buy too much. Our flexibility usually depends on two things:

1. Is it in stock? If you request a sample of a standard Caterpillar D6 roller that we have on the shelf, the MOQ is one piece.

2. Does it require new production? If the part needs to be manufactured, we must set up the forging, casting, and CNC machines. This setup has a cost. Even so, we will often produce a small run of 10-20 pieces for a serious partner, understanding that the real value is the future bulk order.

Here is a typical breakdown of how we handle trial order MOQs for different parts:

| Part Category | Typical Trial MOQ (If In Stock) | Typical Trial MOQ (If Production) | Our Reasoning |

|---|---|---|---|

| Track Rollers / Carrier Rollers | 1 - 10 pieces | 10 - 20 pieces | We need a minimum run on the heat-treatment line. |

| Idlers / Sprockets | 1 - 2 pieces | 2 - 4 pieces | These are high-value; we understand you want to test before committing. |

| Track Chains (Assembly) | 1 set | 1 set | It is impractical to test less than one full chain. |

| G.E.T. (Teeth, Adapters) | 10 - 20 pieces | 50 - 100 pieces | These are small, cast items; the minimum furnace batch is larger 3. |

As you can see, the quantity is always negotiable. We will not force you to buy 500 rollers for a test. A supplier who does that is not confident in their product. We are. We want you to run the test.

Can I mix different parts (e.g., 2 rollers, 2 idlers) in my trial order?

You need to test how different parts work together. Placing multiple trial orders for rollers, idlers, and sprockets is a waste of time and money. We make it easy to combine them.

Yes, absolutely. In fact, I highly recommend it. As a one-stop manufacturer for all undercarriage parts, we want you to test the complete system. Mixing 2 rollers, 2 idlers, and 1 sprocket in a single trial order is completely normal for us.

Mixing parts is not just possible; it is the smartest way to conduct a trial. As a technical expert, you know that undercarriage components form a single, integrated system. The wear life of a track roller is directly affected by the condition of the track chain. The sprocket's wear is linked to the idler's alignment.

The "System" Approach to Quality Testing

Testing one of our new track rollers on an old, worn-out track chain will not give you accurate data. The old chain will prematurely damage the new roller, and you might mistakenly conclude the roller is low quality.

This is why I encourage buyers to take a "system" approach. By ordering a few rollers, idlers, and perhaps a sprocket segment together, you can test how our components interact 4. You get a much more accurate picture of the service life you can expect from our parts. This aligns with your goal of running a realistic field test, which I know is important to you.

How We Manage Mixed Trial Orders

As a direct manufacturer with 20 years of experience, our process is built for this. We are not a trading company that has to source parts from five different factories. All these parts—rollers, idlers, sprockets, chains—come from our own production lines in Fujian 5.

When you request a mixed order, here is our simple process:

1. Unified Quote: You send us your list (e.g., 4x D8 track rollers, 2x D8 carrier rollers, 2x D8 idlers).

2. Inventory Check: Our team checks which items are in stock and which need a short production run.

3. Consolidation: We gather all the parts at a single point in our warehouse.

4. Expert Packaging: The parts are carefully crated together in one custom-built wooden box to minimize shipping costs and prevent damage.

5. Single Shipment: You receive one set of documents (Bill of Lading, Packing List, Invoice) for one shipment.

This efficiency is exactly what our long-term partners value. It saves you time, paperwork, and shipping costs.

| Order Type | Logistics Complexity | Shipping Cost | Our Recommendation |

|---|---|---|---|

| Single Part Trial (e.g., Rollers only) | Low | Moderate | Good for specific part validation. |

| Mixed Part Trial (e.g., Rollers + Idlers) | Low (for us) | Moderate | Highly Recommended. Tests the full system. |

| Multiple Trials from Different Suppliers | High (for you) | High | Inefficient, and test data is hard to compare 6. |

By mixing the order, you are not just testing our products; you are testing our service, our logistics, and our ability to be a one-stop solution 7. This is a key part of the trial.

How long will it take to produce and ship my sample order to Brazil?

You need your test parts fast. Every week spent waiting for a sample is a week you are not serving your customers. We understand that urgency and prioritize clear, honest lead times.

Production is fast. If parts are in stock, we can ship in 7 days. If we must produce them, it takes 20-30 days. Shipping is the longest part. Air freight is 5-10 days, but LCL sea freight to Brazil is 30-45 days.

This is a critical question. As I always tell my partners, the total time has two distinct parts: Production Time (how long it takes us to get the order ready) and Transit Time (how long it takes the shipping company to move it).

Phase 1: Production Lead Time

The time at our factory depends on one thing: stock.

- If In Stock: For common models, we often have parts in our warehouse. In this case, our team just needs to pull the items, conduct a final pre-shipment inspection, and build the export crate. This process usually takes 7 to 15 days.

- If New Production is Needed: If it's a custom part or we are out of stock, we must make it. For a small trial order, this takes 20 to 30 days. This timeline is serious and professional. It includes casting or forging, rough machining, our critical multi-stage heat treatment 8, and final finishing. A supplier who promises 5 days is skipping the proper heat treatment.

Phase 2: Shipping Transit Time (To Brazil)

This is where buyers must make a strategic choice 9. Undercarriage parts are heavy steel. This makes shipping a major cost.

Option 1: Air Freight

- Time: Very fast, around 5-10 days to a major airport in Brazil.

- Cost: Extremely high. A 300kg crate of rollers could cost more to ship than the parts themselves.

- My View: I only recommend this in an emergency, like a "machine down" situation. It is too expensive for a standard trial.

Option 2: Sea Freight (LCL)

- Time: This is the longest part, usually 30 to 45 days from our port in China (like Xiamen) to a port in Brazil (like Santos).

- Cost: Far, far cheaper. This is the standard method.

- My View: This is the most practical and economical choice. We ship LCL (Less than Container Load) for trial orders every day.

| Shipping Method | Production Time (Avg.) | Transit Time to Brazil (Avg.) | Total Time to Your Door | Cost Impact |

|---|---|---|---|---|

| Air Freight | 15 days (Stock) | 7 days | ~22 days | Very High |

| Sea Freight (LCL) | 15 days (Stock) | 40 days | ~55 days | Low |

| Air Freight | 25 days (Production) | 7 days | ~32 days | Very High |

| Sea Freight (LCL) | 25 days (Production) | 40 days | ~65 days | Low |

My advice is to plan ahead. Expect a total of 55 to 65 days for a sea-freight trial order. This realistic timeline prevents surprises and allows you to plan your own field tests.

Will the cost of my sample be refunded if I place a bulk order?

Paying for samples feels like a cost, not an investment. You are worried it is just money you will never get back. We have a policy that turns this cost into a deposit.

Yes, this is a very common practice for us. We typically credit or refund the sample fee (excluding the freight cost) against your first bulk order. This is our way of showing we are partners, and the sample is an investment in our shared success.

This policy is at the heart of our B2B partnership model 10. We are not a B2C company selling one item. We are building a supply chain with you for the next 10 years.

Why We Charge for Samples (and Why It's Good for You)

First, let's be transparent about why we charge for samples. As a manufacturer, I receive many inquiries from people who are not serious business buyers. Charging for a sample ensures that we are dedicating our engineering and production resources to serious partners like you.

You are not just paying for the part; you are paying for:

- Real Materials: We use the same certified steel as our bulk orders.

- Real Labor: Our top technicians run the machines for your sample.

- Real Process: It goes through the same heat treatment and quality control.

A "free" sample from another supplier is often a low-quality piece they had lying around. A paid sample from us is a "First Article" from a real production process. This is what you, as a professional, actually want to test.

Our Policy: The "Sample Credit" System

Our policy is simple and fair. We are not trying to profit from samples. We are qualifying you, just as you are qualifying us.

Here is how it works:

1. You Pay for the Trial: You will pay a Proforma Invoice (PI) for the trial order. This will clearly state the cost of the parts (e.g., $1,000) and the cost of the shipping (e.g., $400 for LCL to Brazil).

2. You Test and Approve: You receive the parts, install them, and run your tests for 500 hours. You are happy with the quality.

3. You Place a Bulk Order: Three months later, you place your first 20-foot container order with us, valued at $30,000.

4. We Apply the Credit: On the $30,000 invoice, we will add a line item: LESS: Trial Order Credit (Order #XXXX) ... -$1,000.

5. Your Final Payment: Your total for the bulk order will be $29,000.

The cost of the parts is refunded. The cost of shipping is not, because that money was paid to the shipping company, not to us.

This system aligns our goals. It proves our confidence. We are betting that you will be so impressed with the sample's quality that you will place a bulk order. This directly addresses the fear of a "bait and switch." We want you to get the bulk order, so we have every incentive to make sure the sample is a perfect representation of our mass production.

Conclusion

Yes, a trial order is essential. We make the process flexible, transparent, and a secure investment in our long-term partnership. It is the first step to building trust.

Footnotes

1. Explanation of Less than Container Load (LCL) shipping for small orders. ↩︎

2. Guide on creating robust real-world testing procedures for industrial product reliability. ↩︎

3. Insights into the economic constraints and minimum batch sizes for industrial casting operations. ↩︎

4. Technical paper detailing the complex operational interaction between track components in a system. ↩︎

5. Article on the concentration and capacity of industrial manufacturing centers, like those in Fujian. ↩︎

6. Academic research discussing challenges in standardizing and comparing test data from multiple suppliers. ↩︎

7. Fundamentals of modern supply chain management and the value of a one-stop sourcing solution. ↩︎

8. Detailed resource on the critical role and process of multi-stage heat treatment in steel components. ↩︎

9. Analysis of strategic sourcing decisions and logistics planning for competitive supply chains. ↩︎

10. Discussion on the mutual benefits and structural integrity of a strong B2B supplier-client partnership model. ↩︎