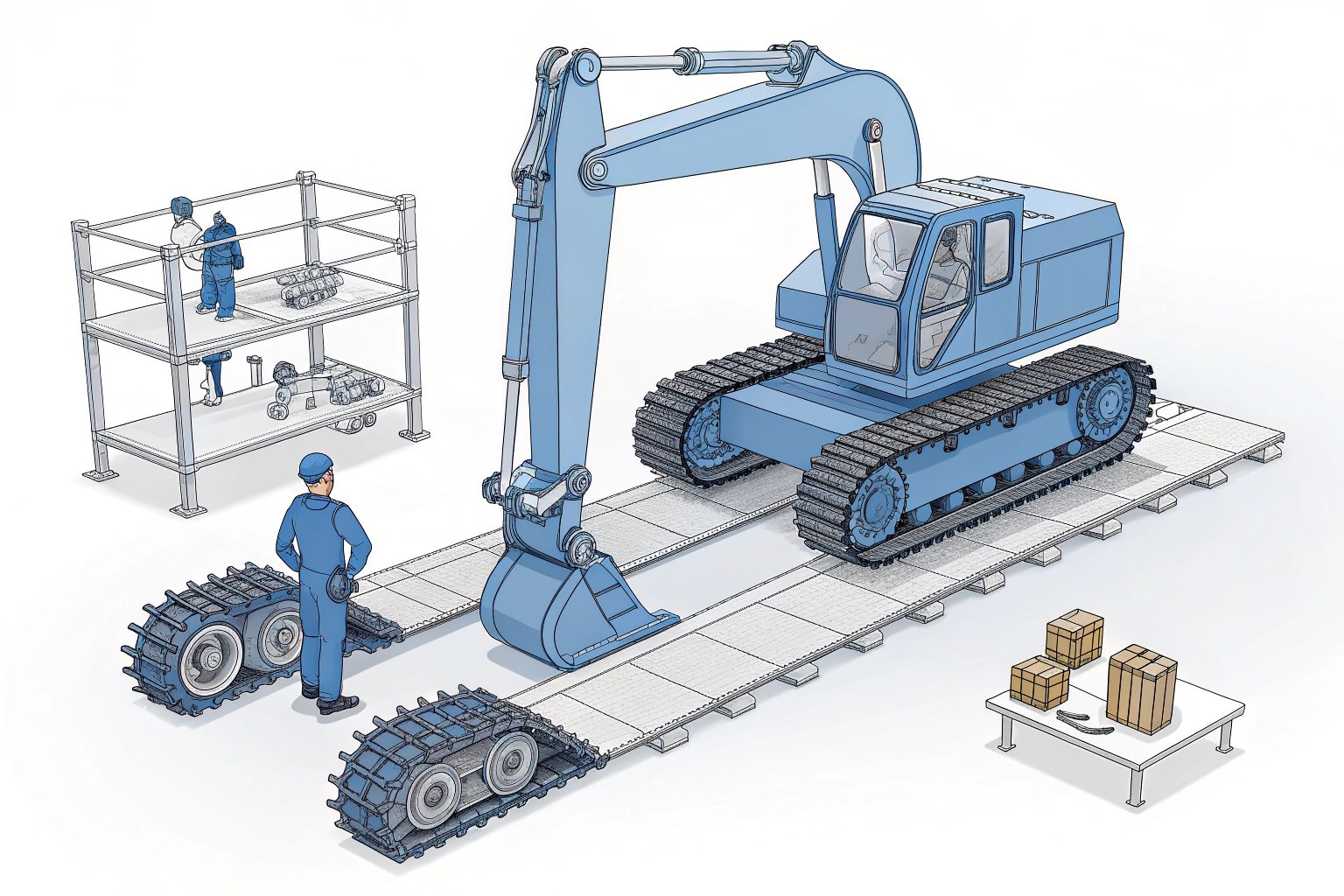

When looking to procure custom-designed undercarriage parts for excavators, providing detailed and precise information is fundamental to ensuring that the parts meet your needs and fit correctly.

To achieve successful customization, collaborate closely with your supplier by giving them thorough details about your equipment, exact specifications, and performance requirements 1.

Below is a guide on what to provide to your supplier.

Do I need to provide a detailed 2D drawing or a 3D CAD model?

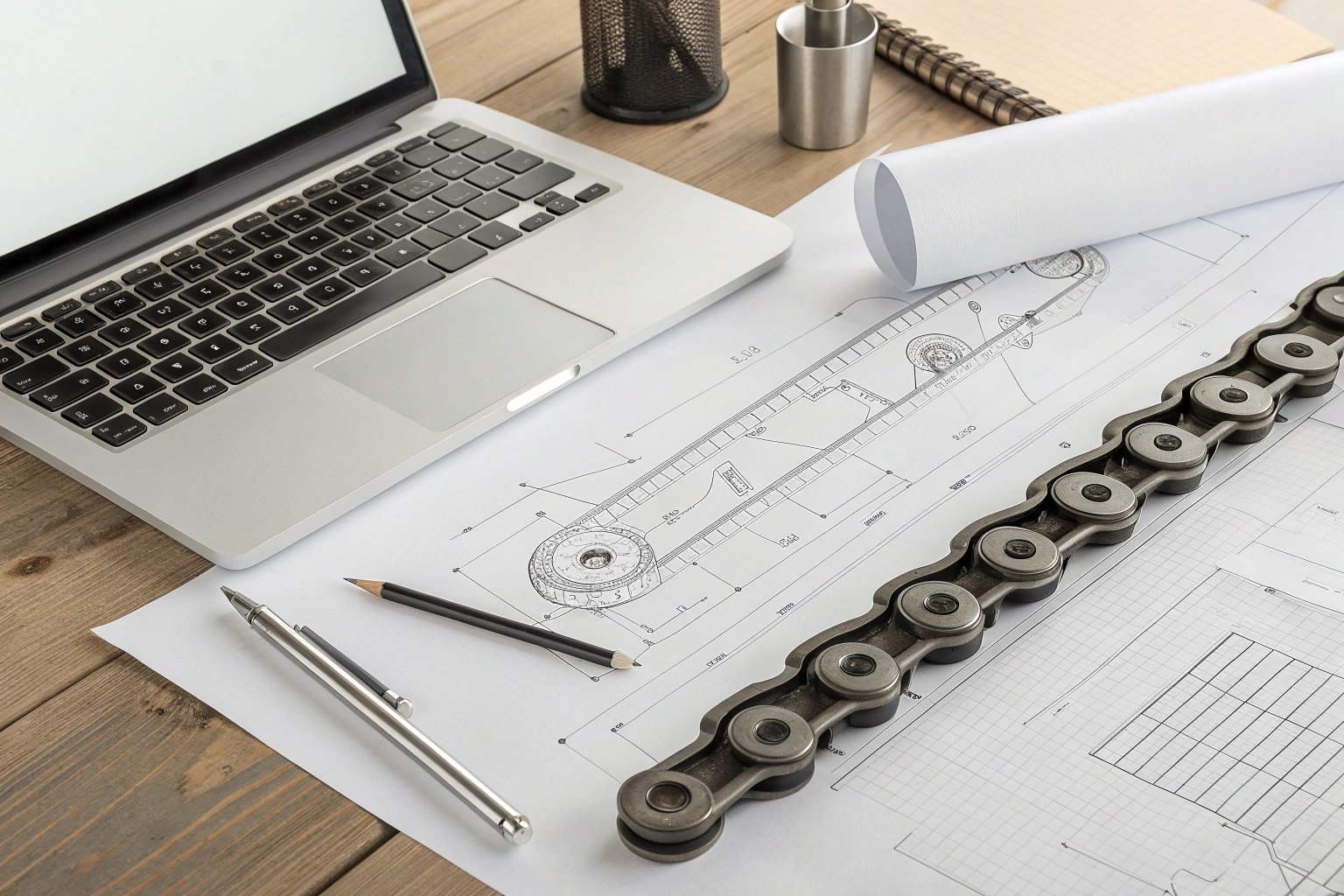

Providing detailed visual materials helps accurately convey your design expectations.

Yes, supplying either a 2D drawing or 3D CAD model—preferably both—will ensure precise manufacturing and reduce the risk of miscommunication.

Design input materials

- 2D Drawings: Show critical dimensions 2, geometries, hole patterns, mounting interfaces, and tolerances.

- 3D CAD Models: Provide a comprehensive view, aiding in virtual fit checks 3 and further adjustments.

- Visual Aids: Photographs of existing parts can assist in highlighting features and assembly interfaces 4.

Design documentation essentials

| Type | Requirement | Benefit |

|---|---|---|

| 2D Drawings | Detailed sketches | Precise dimensional clarity |

| 3D Models | Accurate CAD files | Comprehensive visualization |

| Photographs | Current part images | Feature recognition |

What information about the intended application and performance requirements is necessary?

Understanding the application and performance goals aids in designing parts that meet environmental and operational demands.

Detail the intended usage, including work conditions and performance expectations, to guide your supplier in material and design selections.

Application and performance insights

- Operating Environment: Specify terrain (rocky, muddy) and climate (temperature, humidity) 5.

- Load Capacity: Include weight limits, load cycles 6, and stress details.

- Performance Goals: Describe wear rates or target service life 7 for accurate customization.

Application specifics

| Aspect | Detail | Design Influence |

|---|---|---|

| Terrain | Ground conditions | Material choice |

| Load Capacity | Stress limits | Structural integrity |

| Performance Goals | Service life aim | Durability focus |

How should I specify the material, hardness, and other technical requirements?

Specification precision ensures the parts manufactured withstand intended stresses and wear.

Provide strict material compositions, treatment processes, and hardness requirements, aligning to performance needs and compliance standards.

Technical specifications

- Material Composition: State preferred alloys or grades (e.g., 40Mn2, 50Mn) 8.

- Heat Treatment: Specify desired processes and surface hardness (HRC values) 9.

- Compliance Standards: Indicate necessary regulatory adherence like CE certification 10.

Technical detail points

| Factor | Specification | Impact |

|---|---|---|

| Material Choice | Alloy preference | Strength and durability |

| Heat Treatment | Process details | Resistance to wear |

| Compliance | Certifications | Market suitability |

What is the typical process and timeline for developing a custom part from scratch?

The development process timeline varies with complexity but includes design, prototyping, testing, and full production phases.

A clear understanding of development stages and timelines for custom parts enables timely project completion and cost management.

Development stages

- Design Review: Initial phase involving design validations, often taking weeks.

- Prototyping and Testing: Building and evaluating prototypes typically spans 4-8 weeks.

- Production and Delivery: Full-scale manufacturing and dispatch depend on volume, ranging from 8-12 weeks.

Timeline breakdown

| Stage | Duration | Process Detail |

|---|---|---|

| Design Review | 2-4 weeks | Initial validation |

| Prototype Testing | 4-8 weeks | Assess and refine |

| Production & Delivery | 8-12 weeks | Manufacture and ship |

Conclusion

Providing your supplier with comprehensive details about machine specifications, technical requirements, and application contexts ensures the custom-designed undercarriage parts will fit the needs of your operations perfectly, minimizing errors and achieving desired performance.

Footnotes

1. Guide to defining key performance indicators (KPIs) for heavy machinery parts. ↩︎

2. Learn why precise dimensions are essential for custom part compatibility. ↩︎

3. How digital simulations prevent costly errors in the prototyping phase. ↩︎

4. Understanding how custom parts must connect with existing machine components. ↩︎

5. How temperature and humidity affect metal integrity and performance. ↩︎

6. Guide to calculating load cycles and stress factors on undercarriage parts. ↩︎

7. Factors influencing the operational lifespan of excavator undercarriage components. ↩︎

8. Comparison of common steel alloys like 40Mn2/50Mn for wear resistance. ↩︎

9. Explanation of the Rockwell Hardness Scale (HRC) for material durability. ↩︎

10. What CE certification means for machinery parts and market compliance. ↩︎