A warranty claim is denied. You thought you were covered. But vague contract language just cost you thousands in repairs and downtime. Your contract must be crystal clear before you sign.

In my 20 years at Dingtai, I've seen buyers lose money on bad warranties. A good contract must clearly define the duration (by hours and months), what is covered (defects), what is excluded (wear or abuse), and the exact process for making a claim.

This sounds simple, but the details are where suppliers hide risks. You need to know what to look for to protect your business. Let’s break down exactly what you need to demand in your contract.

What types of failures should be explicitly covered, such as defects in material and workmanship?

Your new track roller cracks in 100 hours. The supplier blames "operation." You know it's a defect. How do you prove it and get your replacement fast without a fight?

I always tell my customers to get specifics. Your warranty must explicitly state it covers "defects in materials and workmanship." This is non-negotiable. It means the part failed because we, the manufacturer, made a mistake, not because you used it.

This part of the contract is the very core of the warranty. It is the supplier's main promise. But these words are not enough on their own. You must define what they mean.

What is a "Defect in Material"?

This means the raw materials used to make the part were bad. The supplier might have tried to save money by using a cheaper steel alloy, or the steel itself had impurities.

- Example: A track shoe cracks in half because the steel was brittle.

- Example: A roller shell has tiny air pockets (porosity) from a bad casting process, causing it to fail under pressure.

Your contract should state that parts will be free from material defects that prevent them from functioning correctly.

Demand Specifics, Not General Promises

A big mistake I see is accepting an "overall undercarriage warranty." This is too vague. A track chain and a track roller have very different jobs and wear at different rates.

A good supplier will provide different warranty terms for different parts. For example, they might offer 4000 hours on a roller but 3000 hours on a chain. This is not a bad sign; it is a sign of honesty and technical understanding.

Here is a simple table you should ask for, defining the types of covered failures.

| Component | Covered Material Defect (Example) | Covered Workmanship Defect (Example) |

|---|---|---|

| Track Chain | Link casting has impurities, causing a crack. | Pin or bushing is not pressed in correctly, causing it to come loose. |

| Track Roller | Steel in the roller shell is too soft. | Seals are damaged during assembly, causing an oil leak. |

| Idler | Metal fork has a hidden crack from casting. | Bearing is not lubricated or sealed properly at the factory. |

| Drive Sprocket | Steel alloy is incorrect, making teeth weak. | Heat treatment was uneven, creating soft spots on the teeth. |

Finally, the contract must state what the supplier will do. If a defect is found, will they just send a new part? Or will they also pay for the shipping and the labor to install it? As a buyer, you should push for repair or replacement 1, including freight and labor costs" for clear-cut defects.

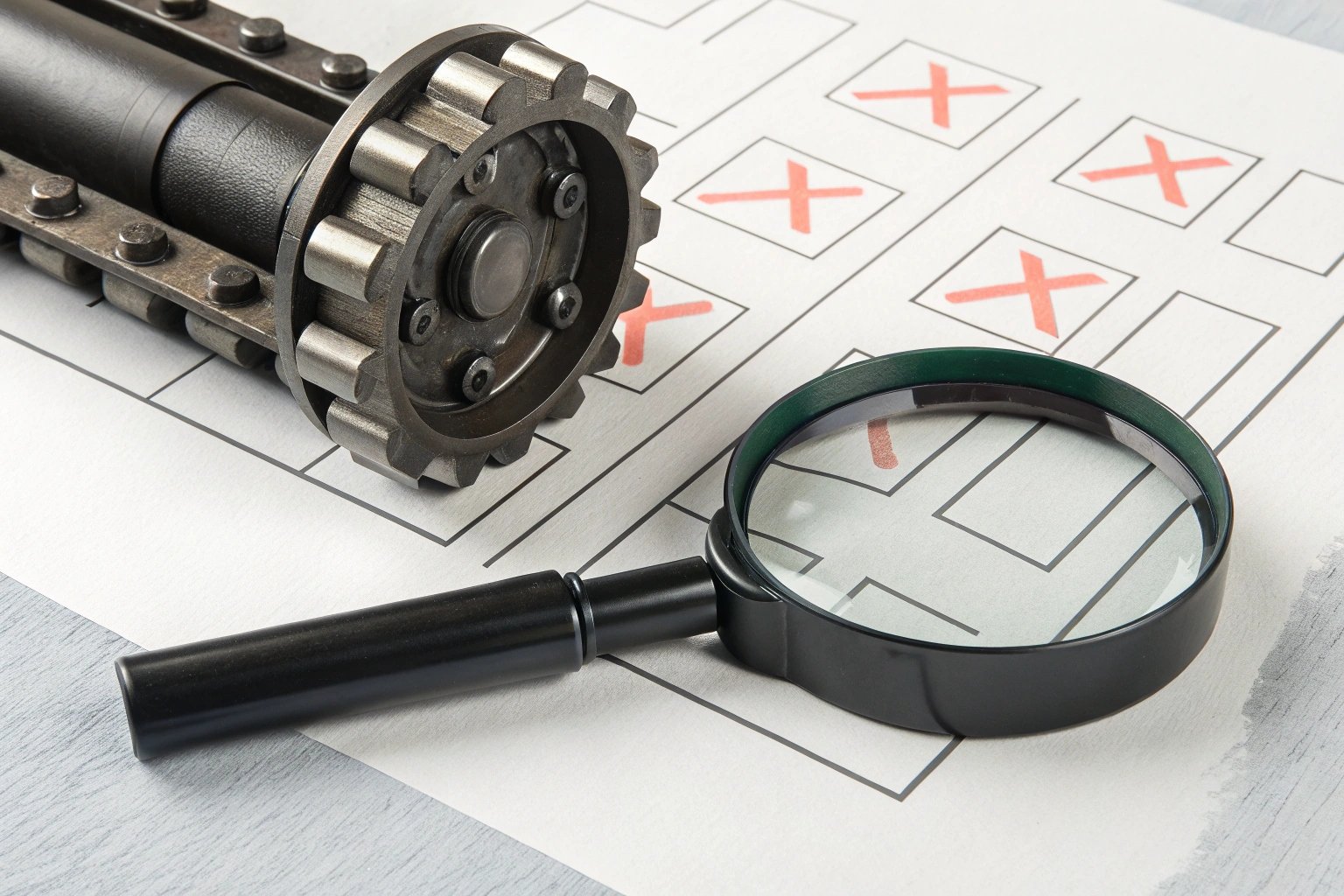

What conditions, like improper installation or abnormal use, would void the warranty?

Your machine goes down. You file a warranty claim. The supplier denies it, pointing to a vague clause about "abnormal use." Now you have no replacement part and no warranty.

From my factory's point of view, we must protect ourselves from claims caused by misuse. But you need protection from vague excuses. I insist that our contracts list exactly what conditions will void the warranty. "Abnormal use" is too vague; demand specific examples.

This list of exclusions is just as important as the list of coverages. A good supplier will have a reasonable list. A bad supplier will use vague words to create loopholes.

Your goal is to make this list as specific and as fair as possible.

Fair and Common Warranty Exclusions

Every warranty will have exclusions. Here are the ones that are standard and fair in our industry:

- Improper Installation: The part was installed without following the manufacturer manual 2. For example, using the wrong tools or not tightening bolts to the correct torque.

- Improper Maintenance: The buyer failed to perform routine maintenance. This is a big one. If you do not keep the undercarriage clean or check track tension, you can cause a failure that is not the manufacturer's fault.

- Misapplication / Overloading: Using the machine for a job it was not designed for. For example, using a standard excavator in a severe demolition environment 3, or constantly exceeding the machine's load capacity.

- Operator Abuse: This includes things like high-speed operation in reverse, driving over sharp objects unnecessarily, or "spinning" the tracks.

- Accidents or Natural Disasters: The warranty does not cover damage from a crash, a fire, or a flood.

- Using Non-Approved Parts: If you modify the undercarriage with parts from another supplier, it can void the warranty on the related components.

Link Exclusions to Specific Maintenance Duties

To make this fair, the contract should be clear about your responsibilities. This actually helps you by creating a clear checklist.

I recommend a table in the contract that links the buyer responsibilities 4 to the warranty.

| Buyer's Maintenance Duty | Frequency (Example) | How it Protects Warranty |

|---|---|---|

| Check Track Tension | Daily | Failure to maintain correct tension (too tight or too loose) is "improper maintenance" and voids warranty on chains, rollers, and idlers. |

| Check for Leaks/Damage | Daily | Not stopping work when a leak is found can cause a small failure to become a total failure, which may not be covered. |

| Clean Undercarriage | As needed (Daily in mud) | Packed dirt and debris (packing) can cause extreme stress and wear. This is often defined as "abnormal use." |

| Use Correct Lubricants | Per Manual | Using the wrong grease or oil can destroy seals and bearings, voiding the warranty. |

If you have this table, you have a clear guide. You can prove you did your part, making it much harder for a supplier to deny a claim.

Should the contract specify that the warranty does not cover normal wear and tear?

Your track shoes are getting thin after 1,000 hours of work. This is normal. But if the warranty is vague, you might get into an argument with your supplier about what "failure" means.

Yes, absolutely. As a manufacturer, I must exclude normal wear. A warranty covers failure, not gradual use. A good contract protects both of us: it stops me from paying for your operating costs, and it stops you from relying on a warranty that won't deliver.

This is the most common point of confusion between buyers and suppliers. You must have a crystal-clear definition of "warranty failure" versus "normal wear and tear" 5.

Defining "Warranty Failure" vs. "Normal Wear"

The contract needs to explain this difference.

-

Warranty Failure: This is a sudden event where the part breaks or stops working long before its expected service life. It is caused by a defect in material or workmanship.

- Example: A track roller shell cracks in half at 500 hours.

- Example: A drive sprocket tooth snaps off at 200 hours.

- Example: A track pin breaks.

-

Normal Wear and Tear: This is the gradual reduction of material as the part does its job. This is an expected operating cost, like buying fuel. It is not a defect.

- Example: Track shoe grousers (the "bars") slowly wear down from 100% to 20% height over 3,000 hours.

- Example: Drive sprocket teeth slowly become "pointed" or "thinned" from meshing with the track chain.

- Example: The internal diameter of a bushing slowly widens from turning on the pin.

A professional supplier (like Dingtai) can often provide you with "wear tables" 6 or "expected service life" estimates under normal conditions. This is not a warranty. It is a baseline to help you plan maintenance.

Why This Protects You, the Buyer

It may feel strange to want this exclusion, but it is a sign of a professional supplier.

- It is Honest: A supplier who promises to warranty "wear" is lying. They will either deny your claim later or go out of business.

- It Manages Expectations: You know you must budget for replacing worn parts. The warranty is your insurance against unexpected, premature failure.

- It Strengthens Your Claim: When a real defect does happen (like a cracked link), the supplier cannot argue that it's just "wear." The contract clearly separates the two.

Here is a table that should be in your contract to make this distinction obvious.

| Component | Normal Wear (NOT Covered) | Warranty Defect (IS Covered) |

|---|---|---|

| Track Shoe | Grouser bars slowly wear down. Bolt holes stretch slightly over time. | A shoe cracks in half or breaks at the bolt hole. |

| Idler | The running surface (where the chain runs) slowly wears down. | The idler leaks oil from a bad seal. The fork or bracket cracks. |

| Track Bushing | The outside diameter slowly wears down from sprocket contact. | A bushing splits open or cracks lengthwise. |

By explicitly stating that normal wear is not covered, you create a stronger, more enforceable contract for the things that are covered.

How do I ensure the warranty terms are clear, fair, and legally enforceable?

You have a signed contract. But it's 20 pages of legal jargon 7 written by the supplier's lawyer. When you have a problem, you find out it's confusing and unenforceable.

I've worked with global B2B buyers like David for decades. A contract is useless if it's not clear and fair. I recommend always defining the duration (hours and months), the remedy (part, labor, or refund), and the dispute resolution 8 process.

This is where everything comes together. A good contract is not about complicated words; it is about simple, clear answers to basic questions. If you cannot understand it, it is a bad contract.

Use "Plain English." 9 Every sentence should be easy to understand. As a supplier, I want my customers to understand the warranty. It builds trust.

Legal Enforceability

Finally, always have your own legal team 10 review the contract, especially in international trade.

- Governing Law: Which country's laws apply? This must be stated.

- Plain Language: If you read a sentence and do not understand it, demand that it be rewritten in simple terms. A good partner will do this. A supplier who refuses is hiding something.

A warranty is not just a piece of paper. It is the foundation of your trust in a supplier. A clear, fair, and enforceable contract is a sign that you are working with a professional partner.

Conclusion

A strong warranty contract is not a luxury; it is essential. Use these points to protect your investment, ensure uptime, and build partnerships with suppliers you can trust.

Footnotes

1. Explanation of standard remedies like repair or replacement in commercial warranties. ↩︎

2. Why following the official service manual is critical for maintaining equipment warranties. ↩︎

3. Understanding the hazards and stresses placed on excavators in demolition environments. ↩︎

4. Overview of typical buyer obligations required to keep a commercial contract valid. ↩︎

5. Legal definition and common interpretations of normal wear and tear in industrial settings. ↩︎

6. Guide to reading and using undercarriage wear limit charts for maintenance planning. ↩︎

7. Common legal terms found in business contracts and what they actually mean. ↩︎

8. Methods for resolving commercial disputes, including arbitration and mediation. ↩︎

9. Benefits of using plain English in legal documents to improve clarity and trust. ↩︎

10. The importance of involving legal counsel in the procurement and contracting process. ↩︎