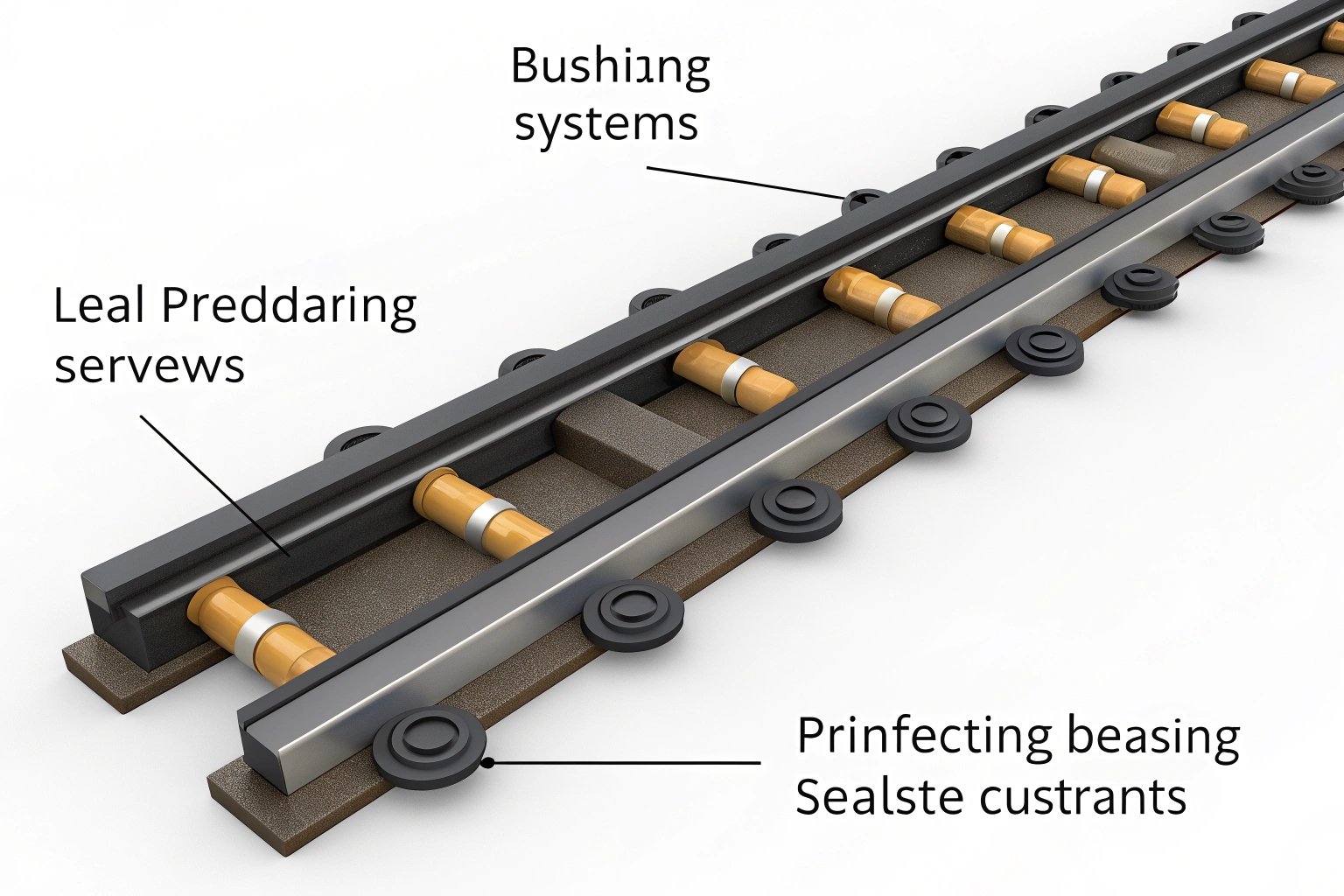

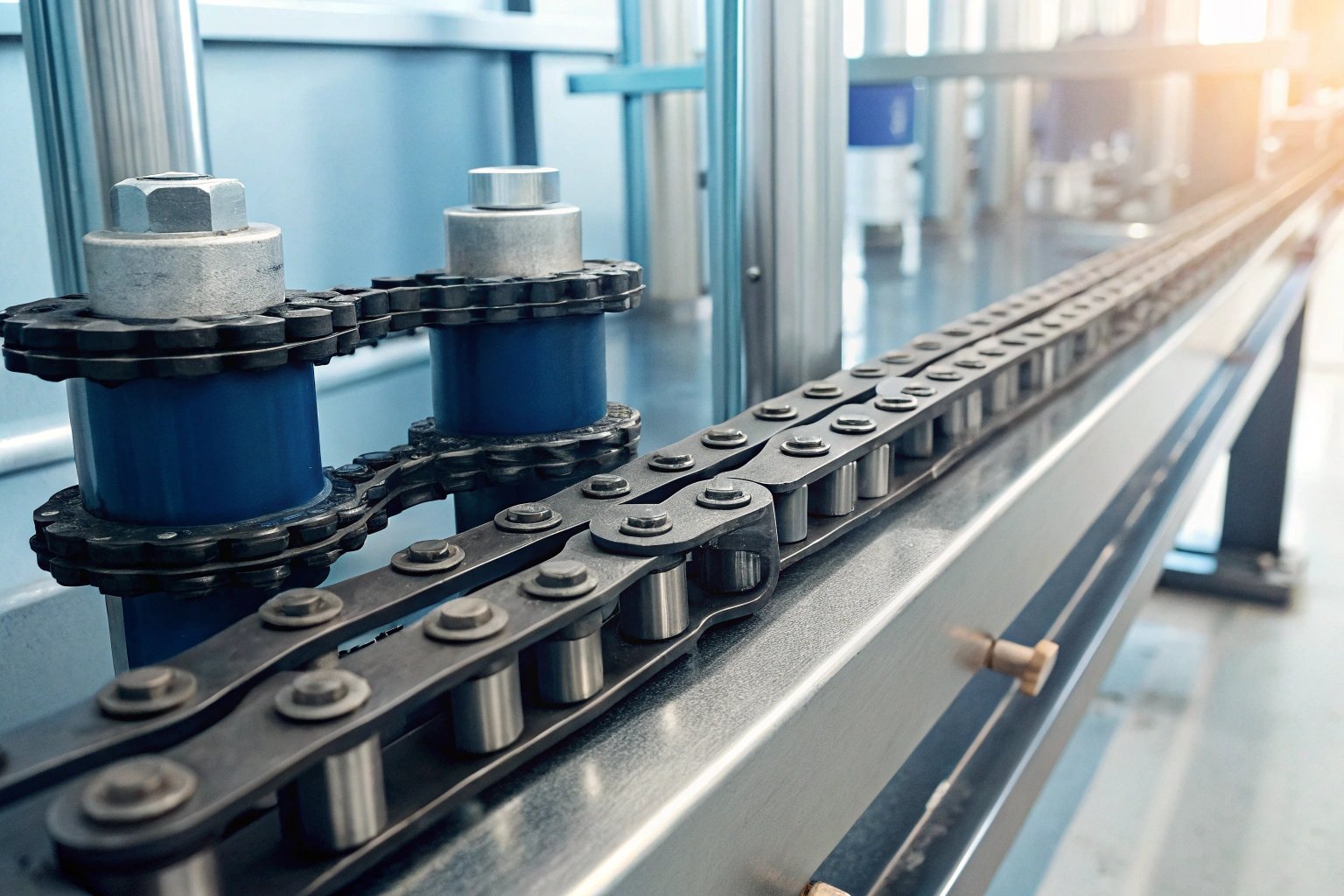

The choice of seal brand and material plays a critical role in the performance and longevity of track chains 1 on excavators. High-quality seals are indispensable for retaining lubrication, blocking contaminants, and ensuring the overall efficiency of undercarriage systems 2.

Seal materials like NBR and FKM are essential for maintaining lubrication and preventing dirt intrusion, enhancing wear resistance and extending the track chain's lifespan.

Here's why seal brand and material matter.

What are the differences between NBR, HNBR, and polyurethane seals for track chains?

Selecting the right seal material 3 involves understanding their different properties and applicable conditions 4.

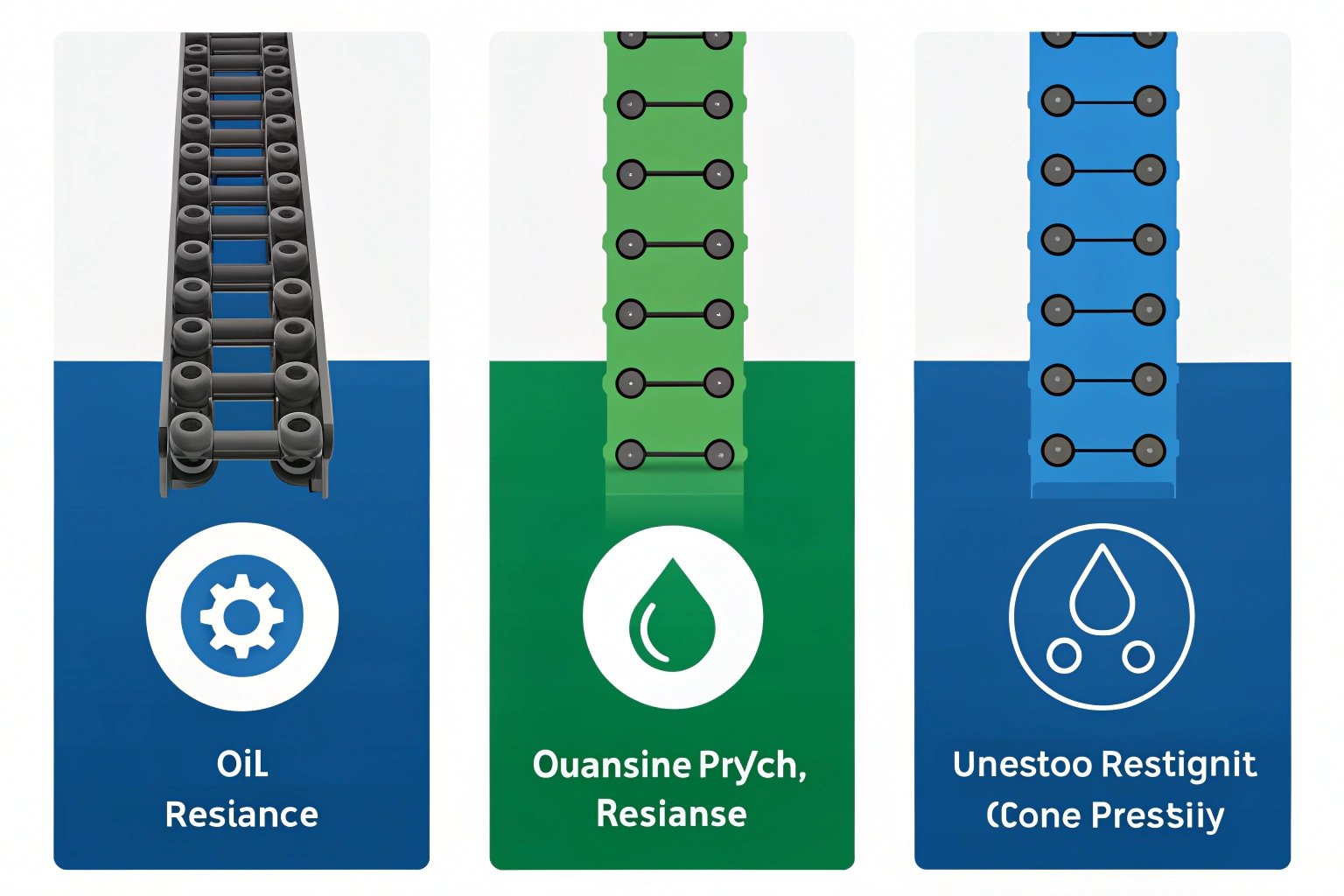

NBR (Nitrile Rubber) is widely used for its oil resistance and moderate temperature range, HNBR (Hydrogenated Nitrile Rubber) provides enhanced durability and temperature resilience, while polyurethane offers high abrasion resistance but lower high-temperature performance.

Material comparisons

- NBR: Suitable for general conditions, resistant to oil, and affordable.

- HNBR: Better thermal stability and mechanical properties than NBR.

- Polyurethane: Exceptional abrasion resistance, not ideal for high heat.

Seal material properties

| Material | Oil Resistance | Temperature Range | Abrasion Resistance |

|---|---|---|---|

| NBR | Excellent | Moderate | Good |

| HNBR | Superior | Broad | Good |

| Polyurethane | Good | Limited | Excellent |

Should I ask the supplier to specify the brand of the seals they use?

Seal brand assurance signals a commitment to quality 5 and performance reliability 6.

Yes, always inquire about the seal brand, as reputable brands provide quality assurance and superior performance parameters, making them a critical consideration for effective operation.

Brand importance

- Quality Consistency: Renowned brands maintain superior standards.

- Engineering Support: Well-known brands offer technical assistance and reliable specifications.

- Market Reputation: Established brands are trusted for their durability and innovation.

Brand inquiry benefits

| Aspect | Advantage | Assurance |

|---|---|---|

| Quality Marks | Maintain standards | Consistency |

| Support Network | Offers guidance | Reliability |

| Proven Record | Trusted performance | Peace of mind |

How do high-quality seals impact the internal lubrication and lifespan of the track pins and bushings?

High-quality seals crucially affect lubrication retention 7 and safeguard against undue component wear 8.

Quality seals maintain internal lubrication and keep contaminants out, thus preventing premature wear and extending the lifespan of track pins and bushings.

Impact on longevity

- Lubrication Conservation: Retains grease/oil, reducing friction and wear.

- Contamination Defense: Blocks ingress of abrasives, water, and other harmful particles.

- Consistency and Reliability: High-quality seals perform well across varied conditions, ensuring system efficiency.

Seal longevity effects

| Function | Benefit | Outcome |

|---|---|---|

| Lubricant Retention | Reduces friction | Extends life |

| Contaminant Protection | Avoids wear | Maintains integrity |

| Performance Stability | Adapts to conditions | Ensures reliability |

For my specific working conditions, what type of seal material should I request?

The working environment influences which seal material 9 offers optimal performance and longevity 10.

Choose seal materials based on your specific environmental challenges, like temperature, exposure to chemicals, or abrasive conditions. High-temperature jobs may require FKM, while standard conditions are well-served by NBR.

Seal material selection

- High Temperature: Request FKM for temperatures up to 260°C.

- Standard Use: NBR provides a cost-effective solution.

- Abrasion-heavy Jobs: Consider polyurethane for its resilience to wear.

Environmental considerations

| Condition | Recommended Material | Reason |

|---|---|---|

| High Temperature | FKM | Heat resistance |

| Standard Conditions | NBR | Cost-effective reliability |

| Abrasion Risk | Polyurethane | Durability |

Conclusion

Choosing the right seal brand and material is pivotal for maximizing track chain performance and durability on excavators. High-quality seals ensure continued lubrication, effective contaminant exclusion, and extend undercarriage lifespan across various operations.

Attention to seal selection plays a significant role in maintaining system efficiency and minimizing operational costs.

Footnotes

1. Tips for maximizing track chain lifespan and heavy equipment performance. ↩︎

2. A guide to excavator undercarriage components and their maintenance. ↩︎

3. Technical guide on comparing different industrial seal materials. ↩︎

4. Data sheets on seal material specifications and chemical compatibility. ↩︎

5. How OEM and high-quality aftermarket brands ensure quality control. ↩︎

6. Case studies on the reliability of components in heavy machinery. ↩︎

7. The science of lubrication retention in high-friction environments. ↩︎

8. Analysis of common causes of premature wear in excavator parts. ↩︎

9. How to match machine components to harsh working environments. ↩︎

10. Optimizing excavator performance and maintenance in challenging conditions. ↩︎