In Brazil, the humid and abrasive environment can swiftly degrade heavy machinery parts. I’ve experienced this firsthand with frequent part failures.

To optimize your undercarriage parts for Brazil's conditions, consider materials like 42CrMo steel 1 for excellent wear resistance. Prioritize rustproof coatings 2, as humidity rapidly causes corrosion, demanding robust preparation.

The combination of high-abrasion from soil and humidity poses challenges, but adopting specific materials and treatments can significantly extend your components' lifespan.

Can you recommend specific materials or heat treatments for my market?

Choosing the right material, especially for tough environments, can be overwhelming. I've learned that not just any steel can withstand Brazil's harsh conditions.

42CrMo alloy steel 3 enhances wear resistance and prevents rust in such climates. Heat treatments, like carburization followed by quenching 4, improve strength and longevity.

Selecting proper materials involves ensuring not only durability but compatibility with environmental demands. In high-abrasion, humid areas like Brazil, specific treatments ensure robust performance.

Material Recommendations

| Material | Benefits | Application |

|---|---|---|

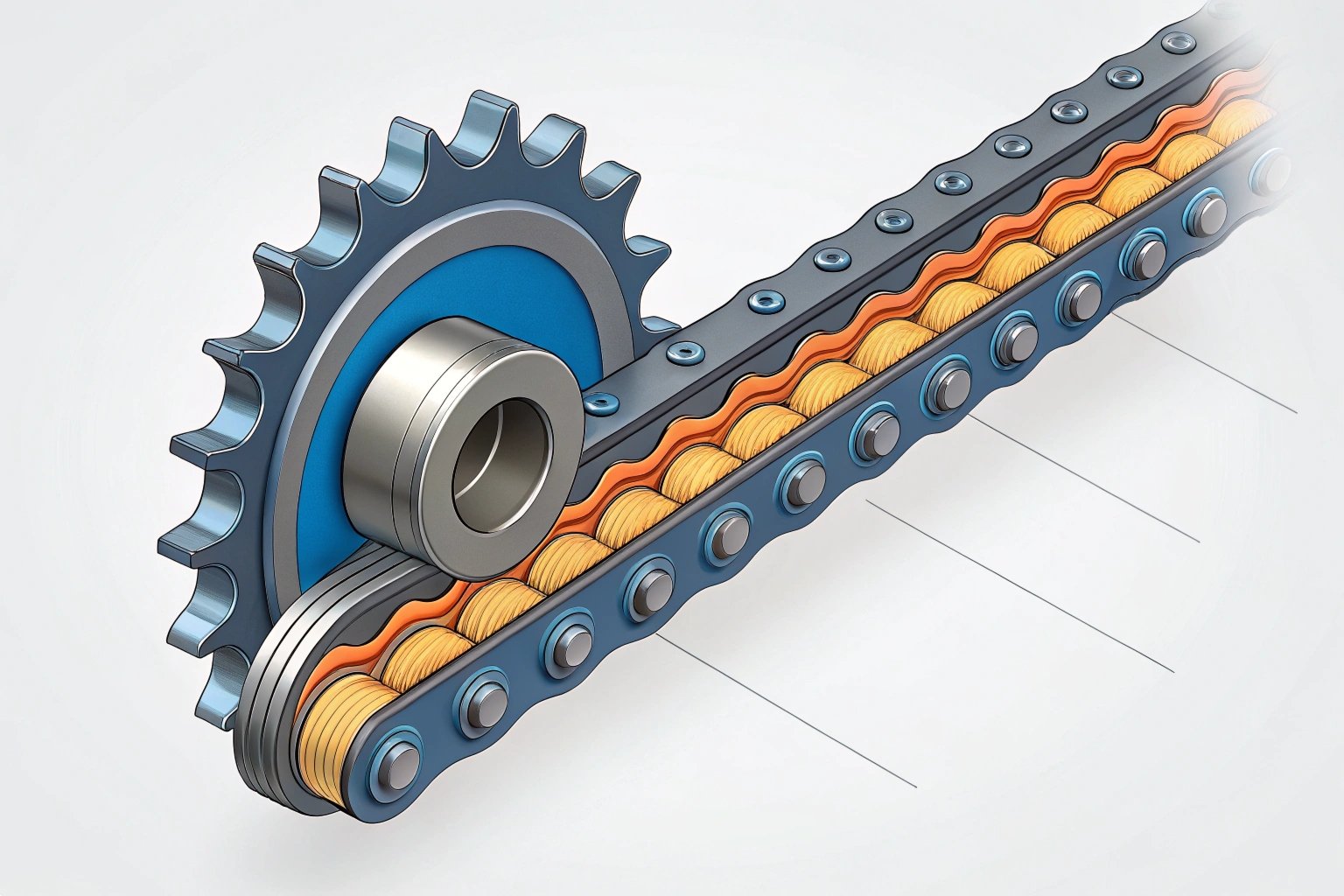

| 42CrMo Steel | Wear resistance, toughness | Track links, drive sprockets |

| Chromium Plating | Corrosion resistance | Surface treatment for all parts |

| Nickel Alloy | Longevity, impact resistance | High-stress components |

Heat treatments, like carburizing and induction hardening 5, increase surface hardness, essential for resisting abrasion. Each treatment aligns with specific mechanical requirements, enhancing the performance of these components under stress.

Do you have case studies of your parts performing in similar environments?

Studying what works and what doesn’t can pave the way for effective solutions. In my exploration, I've found insights from similar challenges 6 to be invaluable.

Our parts performed exceptionally in Brazil’s environment, exhibiting minimal wear. The use of enhanced seals and coatings proved successful in mitigating the challenging conditions.

Looking at past experiences allows us to predict future outcomes and prepare for variables affecting performance 7. Our case studies demonstrate solutions through resistant materials and strategic adaptations.

Performance Metrics

| Parameter | Standard Component | Optimized Component |

|---|---|---|

| Wear Rate | High | Low |

| Rust Presence | Moderate | Minimal |

| Maintenance Frequency | Frequent | Low |

By analyzing performance in similar climates, proactive measures become clear. Data-driven approaches guide optimizations, ensuring reliable operations 8 even amid Brazil's vilest conditions.

Can you customize a product (e.g., enhanced seals) for my needs?

Customization isn’t just for aesthetics; it’s crucial for functionality too. When it comes to machinery, a tailored approach makes all the difference.

Enhanced seals, like a dual floating system 9, effectively block debris and moisture. This modification for Brazilian conditions ensures protection and performance longevity.

Adapting component designs to specific terrains and climates propels operational success. Such customizations bridge the gap between standard designs and specialized requirements.

Custom Engineering Solutions

| Feature | Description | Benefits |

|---|---|---|

| Dual Seals | Advanced barrier against debris | Prolongs part life |

| Self-lubricating Pins | Integrated lubrication systems | Reduces maintenance |

| Reinforced Design | Thicker, stronger track shoes | Enhanced impact resistance |

The goal is to minimize downtime while maximizing functional integrity. Custom solutions 10 provide structural reinforcement, balancing efficacy with durability.

What data do you need from me to suggest an optimized solution?

Utilizing data ensures decisions are well-informed. I’ve learned that providing specifics can lead to customized, effective solutions.

Local soil composition and abrasion levels significantly guide component selection. Additionally, environmental factors dictate necessary protection measures.

Data-driven decisions greatly enhance machinery performance. Insights gained from detailed data shape informed choices and tailored solutions.

Required Data Types

| Data Type | Importance | Example Use |

|---|---|---|

| Soil Composition | Determines material suitability | Component resistance |

| Humidity Levels | Guides anti-corrosion measures | Sealant selection |

| Terrain Details | Affects design specifications | Structural enhancements |

Data provides a roadmap for optimal engineering and product selection. It’s about building resilience, underpinning success through informed preparation.

Conclusion

Optimizing undercarriage parts requires strategic material selection and tailored engineering solutions, ensuring resilience in Brazil's harsh environments.

Footnotes

1. Read more about the properties and applications of 42CrMo steel in high-wear environments. ↩︎

2. Explore the importance of corrosion-resistant coatings specifically for heavy machinery components. ↩︎

3. Discover why this high-strength alloy is chosen for its superior performance and resistance in challenging climates. ↩︎

4. Learn how carburization and quenching heat treatments fundamentally improve the strength and longevity of steel parts. ↩︎

5. Understand the benefits of using induction hardening to increase surface hardness and improve abrasion resistance. ↩︎

6. Review technical paper insights on material choices for mining equipment in abrasive and corrosive conditions. ↩︎

7. Analysis of environmental factors and mechanical wear that affect component performance over time. ↩︎

8. Learn how data-driven decision-making guides product optimization for increased performance and reliability. ↩︎

9. Technical details on seal design principles, including dual floating systems, for effective contaminant exclusion. ↩︎

10. Explore research on customized manufacturing processes for enhanced component structural integrity and durability. ↩︎