To ensure reliability in our bulldozer undercarriage parts, consistent steel quality 1 is paramount. I need to confirm that each batch undergoes rigorous spectrometer analysis 2 to verify its composition and adherence to equipment standards.

By providing a detailed Material Test Certificate (MTC) for every steel batch received, suppliers offer verifiable proof of spectrometer analysis results. When certificates include key elements like testing methods and elemental quantifications, they assure that the material meets requisite quality standards.

To deepen our understanding, let's examine how batch-specific test documentation 3 supports quality assurance and keeps suppliers accountable.

Can I get a copy of the raw material composition report with my shipment?

I demand transparency when it comes to the components in my machinery. Receiving detailed reports of the steel composition 4 ensures peace of mind and verifies the quality of my order.

Raw material composition reports typically accompany shipments as MTCs, giving precise chemical makeup details for the steel used. These documents are essential for validating the material's compliance with international and industry-specific standards.

When suppliers provide comprehensive reports, it reinforces trust and support for further scrutiny if necessary. The certificate displays the elemental composition, often using Optical Emission Spectrometry (OES), tracing each batch to standards like ASTM or ISO.

Ensuring Thorough Testing

-

Highlight: Testing Methods Test methods, such as OES, should be detailed in reports, confirming that rigorous analytical processes are in place.

-

Element Analysis Vital constituents like carbon, manganese, and chromium 5 are quantified to ensure not only chemical consistency but also structural integrity for manufacturing.

-

Independent Verification Requesting third-party validation 6 further boosts confidence in compliance, assuring that the steel does not deviate from set standards.

Trusting the steel quality relies on these reports, providing much-needed scrutiny and assurance.

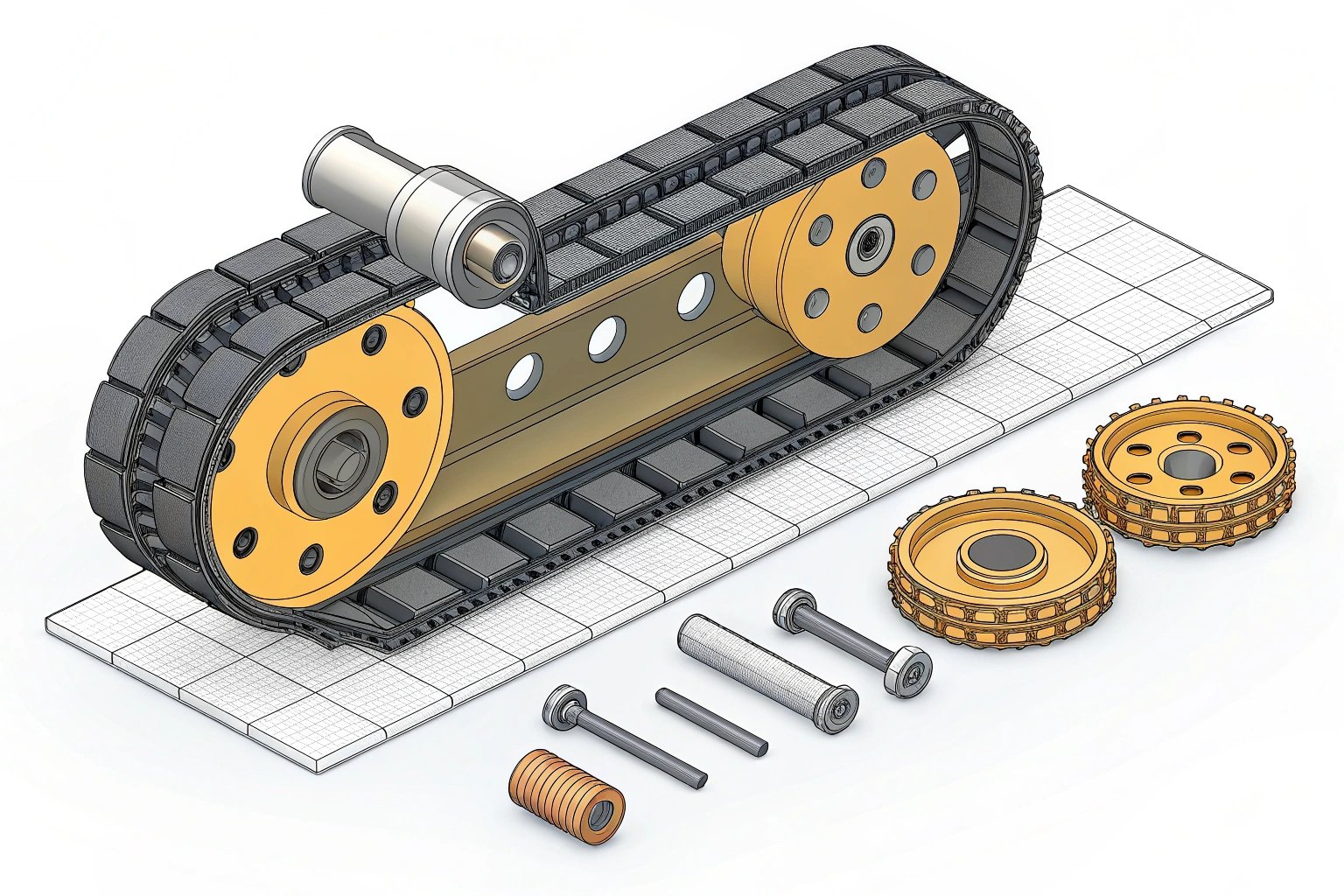

What specific steel grades do you use for different parts like track rollers and idlers?

When it comes to heavy machinery, steel grades 7 dictate performance. I want to be informed about the exact specifications used to produce each component of my bulldozer parts.

Specific steel grades tailored for individual components, such as track rollers and idlers, determine durability and function. Certification reports specify the steel variant used, indicating its suitability for the machinery part.

Delving into suitable steel variants ensures parts function optimally under stress. Manufacturers utilize grades like 4140 or 1050, known for durability and resistance.

Tables of Steel Utilization

| Part | Steel Grade | Characteristics |

|---|---|---|

| Track Rollers | 4140 | High strength, excellent wear resistance |

| Idlers | 1050 | Good toughness, enhanced surface hardness |

By aligning steel properties with component demands, manufacturers ensure effective operation, reducing wear and maximizing lifespan.

Understanding these choices aids in affirming manufacturing integrity, ensuring performance and reliability.

How do you ensure your steel suppliers provide consistent quality?

Supplier selection is crucial for ensuring component consistency. We assess suppliers rigorously to confirm a reliable supply of high-quality steel.

Regular audits and demand for international certifications like ISO 9001 8 ensure that suppliers maintain high production standards. Documented testing processes become indispensable, emphasizing their dedication to consistency.

Proactive measures include supplier audits, cementing reliability and competence. Key components include certification-demand, production scrutiny, and performance checks.

Supplier Quality Assurance

-

International Standards Compliance with standards ensures uniformity and quality across batches, heightening trust.

-

Documented Testing Testing procedures validated by certificates provide referenceable proof of ongoing supplier diligence.

-

Regular Audits Supplier audits drive continuous improvement, validating adherence to quality expectations.

By ensuring supplier commitment to these practices, a stable supply of premium steel remains attainable, epitomizing the transformative role of stringent oversight.

What happens if a batch of steel fails your spectrometer test?

Knowing contingency plans in case of material issues brings reassurance. How failures are managed speaks volumes about supplier accountability.

In events where a batch fails spectrometer tests, immediate corrective measures like batch rejection 9 and detailed analysis of causative factors take precedence. Quick actions ensure problem resolution without affecting production timelines.

A flexible, responsive approach allows seamless correction and reorder strategies. Communication protocols guarantee swift response and action.

Material Discrepancy Management

-

Rejection Protocols Faulty batches face immediate rejection to ensure no substandard material enters production.

-

Analytical Follow-Up Investigations 10 reveal cause, preventing recurrences and optimizing processes.

-

Responsive Reorder Speedy replacement strategies ensure uninterrupted operations, mitigating potential delays.

By putting corrective action front and center, risk is minimized, reinforcing supplier accountability and quality assurance.

Conclusion

Thorough verification of steel quality through spectrometer analysis ensures bulldozer part reliability. Rigorous documentation confirms every batch meets standards.

Footnotes

1. Read ISO's guidance on ensuring consistent steel quality in manufacturing. ↩︎

2. Understand how spectrometer analysis (OES) verifies steel composition. ↩︎

3. View ASME's explanation of Material Test Certificates (MTCs) for material traceability. ↩︎

4. Explore a comprehensive guide on different chemical elements in steel composition. ↩︎

5. Learn about the roles of carbon, manganese, and chromium in steel's strength and durability. ↩︎

6. Information on the benefits of independent third-party verification for supplier compliance. ↩︎

7. Detailed technical comparison of various steel grades and their applications in machinery. ↩︎

8. Official resource explaining the requirements and benefits of ISO 9001 quality management certification. ↩︎

9. Protocol steps for the inspection and rejection process of faulty material batches in quality control. ↩︎

10. Guide to conducting root cause analysis for manufacturing quality failures to prevent recurrence. ↩︎