I know the frustration of watching a machine sit idle because a "bargain" track chain snapped or a roller seized up just weeks after installation. It feels like throwing money into a pit while your project deadlines slip away and repair costs climb.

Discovering quality excavator undercarriage parts requires verifying material hardness (HRC 50–55), choosing forged components over cast ones, and ensuring ISO9001 certification. High-quality parts use boron steel or manganese alloys and undergo 100% pre-delivery inspection to guarantee durability and perfect fit for brands like Caterpillar, Komatsu, and Hitachi.

Finding a partner who understands that every hour of downtime is a loss for your business is the real secret to a stable supply chain. If you keep reading, I will show you exactly how to spot the difference between cheap junk and professional-grade steel that keeps your fleet moving.

How can I distinguish between "budget" aftermarket parts and premium OEM-spec components?

I used to think all steel looked the same until I saw a budget sprocket shatter under a heavy load on a job site. That moment taught me that "saving" a few hundred dollars on the front end often costs thousands in emergency repairs and lost labor.

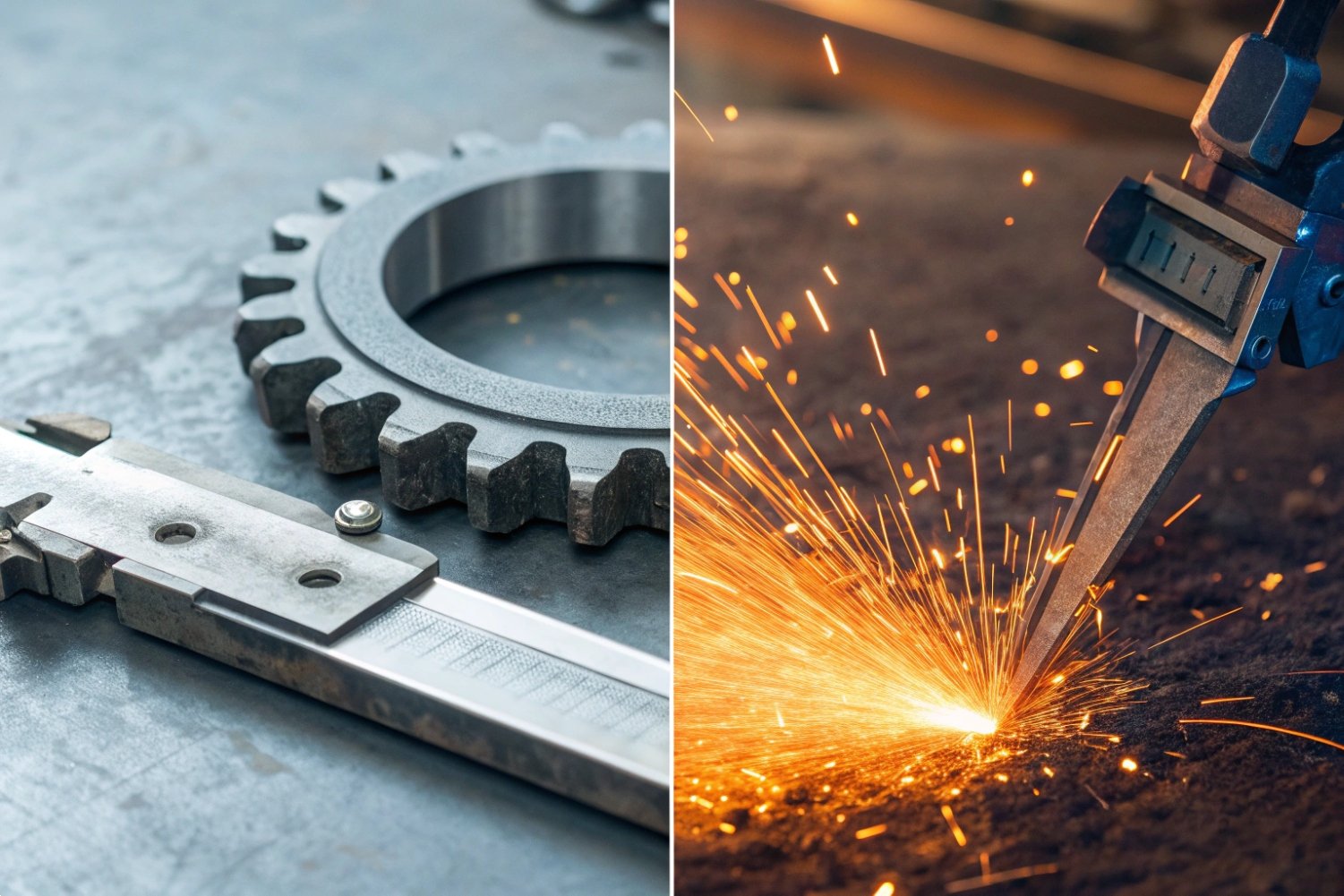

To distinguish premium components, look for deep heat treatment, precise machining tolerances, and the use of specialized alloys like boron steel. Premium parts match OEM specifications for track pitch and bolt hole positions exactly, whereas budget parts often have inconsistent hardening and poor fitment that causes accelerated wear.

The Science of Steel and Heat Treatment

When I talk about quality, I am really talking about what happens inside the metal. Premium undercarriage parts are not just shaped like the originals; they are built to survive the brutal friction of a construction site. The biggest difference lies in the heat treatment process 1. Budget manufacturers often only harden the very surface of a roller or sprocket. This thin layer wears through quickly, exposing soft metal that deforms under pressure.

Premium manufacturers use induction hardening or through-hardening to achieve a specific depth. For example, a high-quality track roller 2 should have a hardness rating of HRC 50–55. This ensures the part can resist wear for thousands of hours. In my experience, parts made from boron steel 3 offer much better toughness than standard carbon steel. Boron steel stays strong even after the heat treatment process, which prevents the parts from becoming brittle and cracking.

Forging vs. Casting: Why it Matters

The way a part is made changes its internal strength. Most high-stress components, like track chains and segments, should be forged rather than cast. Precision forging 4 compresses the metal and creates a continuous grain flow. This makes the part much more resistant to impact. Cast parts often have tiny internal air bubbles or "porosity" that you cannot see with the naked eye. Under the weight of a 30-ton excavator, those tiny bubbles become the starting point for a major crack.

| Feature | Budget Aftermarket | Premium OEM-Spec (Dingtai) |

|---|---|---|

| Material | Standard Carbon Steel | 40Mn2, 40MnB (Boron Steel) |

| Hardening Depth | 2mm - 3mm | 5mm - 8mm (Deep Induction) |

| Manufacturing | Mostly Casting | Precision Forging |

| Fitment | Loose tolerances | Exact OEM Match |

| Surface Finish | Rough | Precision Ground |

Precision Machining and Seal Quality

Another tell-tale sign of a premium part is the quality of the seals and bushings. A "budget" track chain might look fine, but if the heavy-duty seals 5 are made of cheap rubber, they will leak oil or let in dirt within months. Once dirt gets inside a pin and bushing, it acts like sandpaper, grinding the metal away from the inside out. Premium parts use high-quality, heavy-duty seals that keep lubrication in and contaminants out, which is why they last twice as long in muddy or sandy conditions.

What role do manufacturer certifications like ISO9001 play in my purchasing decision?

I have seen many suppliers claim they have "the best quality," but without a formal certification, those are just empty words. When I am responsible for a large fleet, I need more than a promise; I need a system that ensures the thousandth part is just as good as the first one.

ISO9001 certification ensures that a manufacturer follows a strict, documented quality management system. It means every step, from raw material sourcing to final heat treatment, is monitored and recorded. For a buyer, this reduces the risk of receiving a "bad batch" and guarantees consistent product performance.

Accountability in Production

ISO 9001 6 is not just a piece of paper on the wall. It is a commitment to traceability. If a track link fails in the field, a certified manufacturer can look back at their records to see which batch of steel was used, who performed the heat treatment, and what the test results were that day. This level of accountability is what separates professional factories from small, unregulated workshops.

In my years in the industry, I have found that certified suppliers are much more likely to have an internal lab. They don't guess if the steel is strong enough; they test it. They check the chemical composition of the manganese and the hardness of the rollers before anything is packed into a crate. This prevents the "quality roller coaster" where one shipment is great and the next one is a disaster.

Third-Party Verification

Beyond ISO9001, certifications from companies like SGS Group 7 add another layer of trust. These organizations act as independent eyes. They visit the factory and verify that the machines are maintained and the workers are following the correct procedures. For a procurement manager in the US or Europe, this third-party verification is essential because you cannot visit every factory in China personally. It provides the "peace of mind" that the supplier meets international standards for safety and durability.

Comparison of Certification Benefits

| Certification | What it Proves | Benefit to the Buyer |

|---|---|---|

| ISO 9001 | Consistent Quality Management | Fewer defective parts and stable supply. |

| SGS Audited | Physical Factory Verification | Confirms the supplier is a real manufacturer. |

| CE Marking | Safety and Technical Compliance | Meets standards for international trade. |

| Material Reports | Chemical & Hardness Data | Proof that the steel matches the spec. |

How do I find direct-from-factory deals that don't compromise on material quality or durability?

I always tell my clients that the shortest distance between your machine and a replacement part is a direct line to the factory. Cutting out the "middleman" can save you 20-30% in costs, but you have to be careful not to fall into the trap of a "trading company" pretending to be a factory.

To find genuine factory deals, look for suppliers with their own R&D teams, over 100 employees, and specific manufacturing experience—ideally 20+ years. Genuine factories like Dingtai provide technical drawings, material reports, and customization options that trading companies simply cannot offer, ensuring you get factory pricing with OEM quality.

Identifying a Real Manufacturer

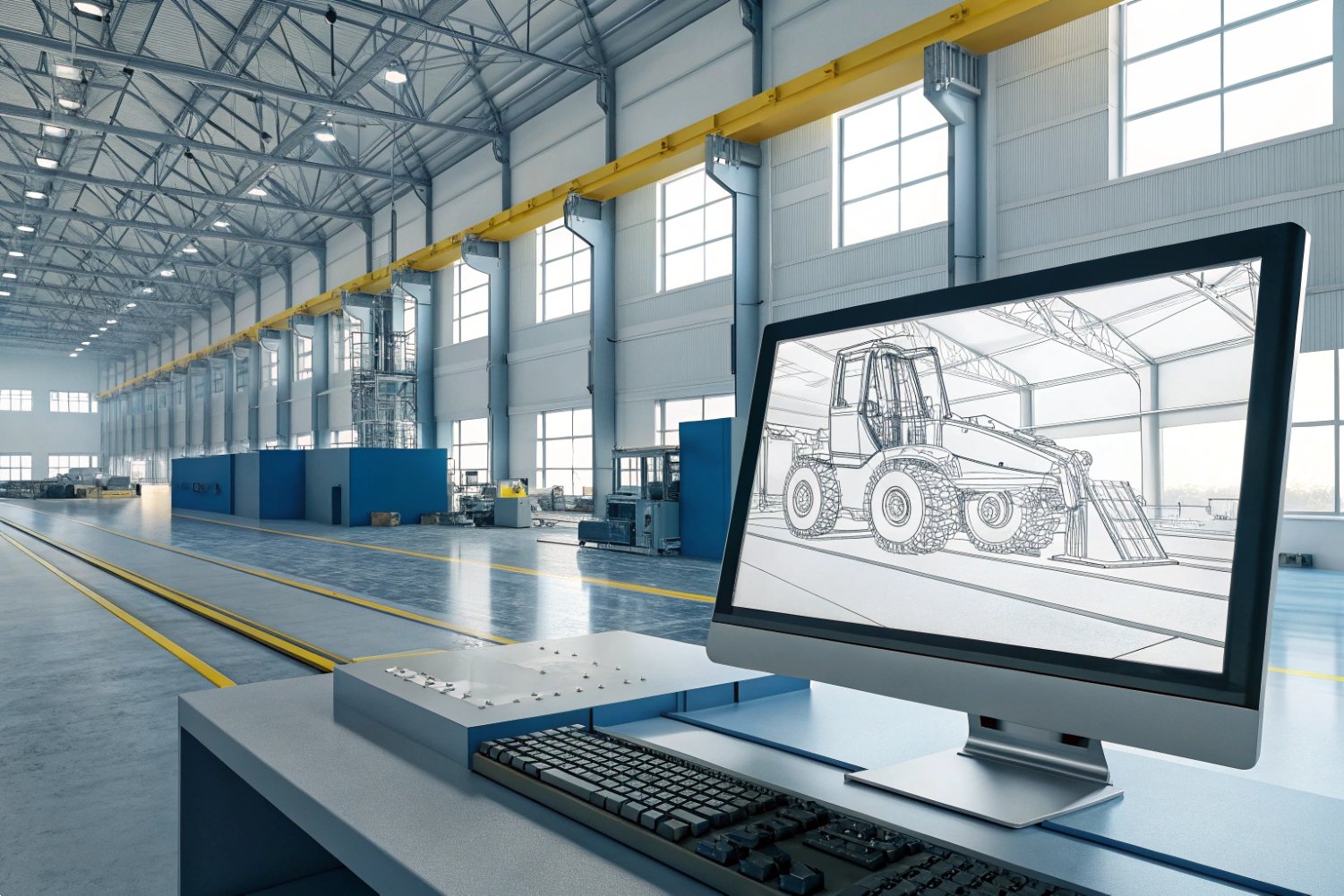

The internet is full of "suppliers," but many are just offices with a laptop. A real factory will be happy to show you their production lines via video call. They will have heavy machinery like friction welding machines 8, giant forging hammers, and heat treatment pits. When I talk to a supplier, I ask technical questions about their heat treatment depth or their manganese content. A manufacturer will answer immediately. A trading company will say, "Let me check and get back to you."

Buying direct also means you get better technical support. If you have a specific machine working in a high-impact mining environment, a factory can suggest a "heavy-duty" version of a track group with wider shoes or reinforced links. They have the engineering power to adjust the product to fit your specific needs, which is something a simple reseller cannot do.

The Value of Experience

Look for a manufacturer with at least two decades of history. The undercarriage industry has a steep learning curve. It takes years to perfect the "recipe" for heat-treating a sprocket so that it is hard on the teeth but not so brittle that it snaps. A factory with 20+ years of experience has already made all the common mistakes and fixed them. They have a deep library of technical drawings 9 for brands like Caterpillar, Komatsu, and Hitachi, which ensures the parts will bolt on perfectly without any modifications.

Sourcing Checklist for Direct Buying

- Request a Video Tour: Ask to see the actual production of track rollers or chains.

- Check the Employee Count: Real factories usually have 100+ workers and dedicated technical staff.

- Ask for Technical Drawings: A factory can provide exact dimensions and CAD files for compatibility checks.

- Look for OEM History: See if they have manufactured parts for major global brands.

Why should I look for suppliers who provide comprehensive 100% pre-delivery inspection videos?

I remember a client who received a full container of idlers only to find that the mounting holes were off by 2 millimeters. It was a nightmare. The parts were useless, and the shipping costs to send them back were higher than the value of the parts. Since then, I have insisted on "proof before payment."

Suppliers providing 100% pre-delivery inspection (PDI) videos allow you to verify dimensions, surface finish, and quantity before the goods leave the factory. This practice eliminates "shipping surprises," ensures the parts match your order exactly, and demonstrates a level of transparency that build long-term trust in a B2B relationship.

Eliminating the "Hidden Defect" Risk

In a global supply chain, you cannot afford to receive a defect. A video of the inspection process is like being at the factory yourself. You can see the worker using a digital caliper 10 to check the track pitch. You can see the smooth finish on the roller tread. Most importantly, you can see that the items are packed securely. Undercarriage parts are incredibly heavy; if they are not packed correctly in steel-strapped crates, they will destroy each other during a 30-day ocean voyage.

When a supplier offers this service, it shows they are confident in their work. Only a factory that has a rigorous quality control process is willing to film it. It forces the workers to be more careful because they know the customer is watching. For my business, this is a "must-have" requirement. It turns a risky international purchase into a safe, transparent transaction.

Building Strategic Partnerships

For a procurement director, the goal isn't just to buy parts; it's to find a partner you can trust. Suppliers who provide inspection data and videos are treating the relationship as a partnership. They want you to be successful because they know that if your machines stay running, you will come back for more. This transparency leads to better communication and faster resolution if a problem does occur. In the long run, the time saved by avoiding mistakes is worth more than the parts themselves.

Sample Inspection Data Table

| Inspection Point | Method | Target Result |

|---|---|---|

| Hardness | Rockwell Tester | HRC 50–55 |

| Dimensions | Digital Caliper | ± 0.05mm of OEM Spec |

| Seal Leakage | Air Pressure Test | Zero Pressure Drop |

| Visual Check | 4K Video/Photo | No cracks, smooth finish |

| Packaging | Inspection | Steel-strapped wooden crates |

Conclusion

Finding quality excavator undercarriage parts is about looking past the price tag and focusing on steel grade, heat treatment, and factory certifications. This approach ensures long-term machine reliability.

Footnotes

1. Technical guide explaining the critical stages and impacts of the heat treatment process. ↩︎

2. Industry forum for real-world reviews and advice on excavator track roller maintenance. ↩︎

3. Resource detailing the properties and industrial benefits of using boron steel in parts. ↩︎

4. Insights from the forging association on how precision forging improves component strength. ↩︎

5. Engineering overview of high-quality heavy-duty seals for demanding industrial machinery. ↩︎

6. Official ISO page defining the requirements for a global quality management system. ↩︎

7. Global inspection services providing third-party verification for manufacturing compliance. ↩︎

8. Technical resource on the efficiency and strength of friction welding in heavy production. ↩︎

9. Industry-standard software for viewing and creating accurate engineering technical drawings. ↩︎

10. Manufacturer information on high-precision digital caliper tools for quality inspection. ↩︎