Your bulldozer's undercarriage accounts for up to 50% of its total maintenance costs. Choosing the right undercarriage parts for bulldozers isn't just about finding a replacement; it's a strategic decision that directly impacts your project's profitability. A single unexpected failure can cost 5-10 times more in downtime than the part itself. This guide gives you the field-proven insights to make smarter choices, extend component life, and keep your machines running.

Last Updated: January 2025

Estimated Reading Time: 8 minutes

This Article Will Answer:

- What are the critical undercarriage components and their functions?

- When is the right time to inspect and replace your track assembly parts?

- Which offers better value for your fleet: OEM or high-quality aftermarket parts?

- How do job site conditions dictate your parts selection?

- What simple maintenance habits can extend undercarriage life by up to 40%?

- How to identify a truly reliable undercarriage parts supplier?

What Are the Key Components of a Bulldozer Undercarriage and What Is Their Function?

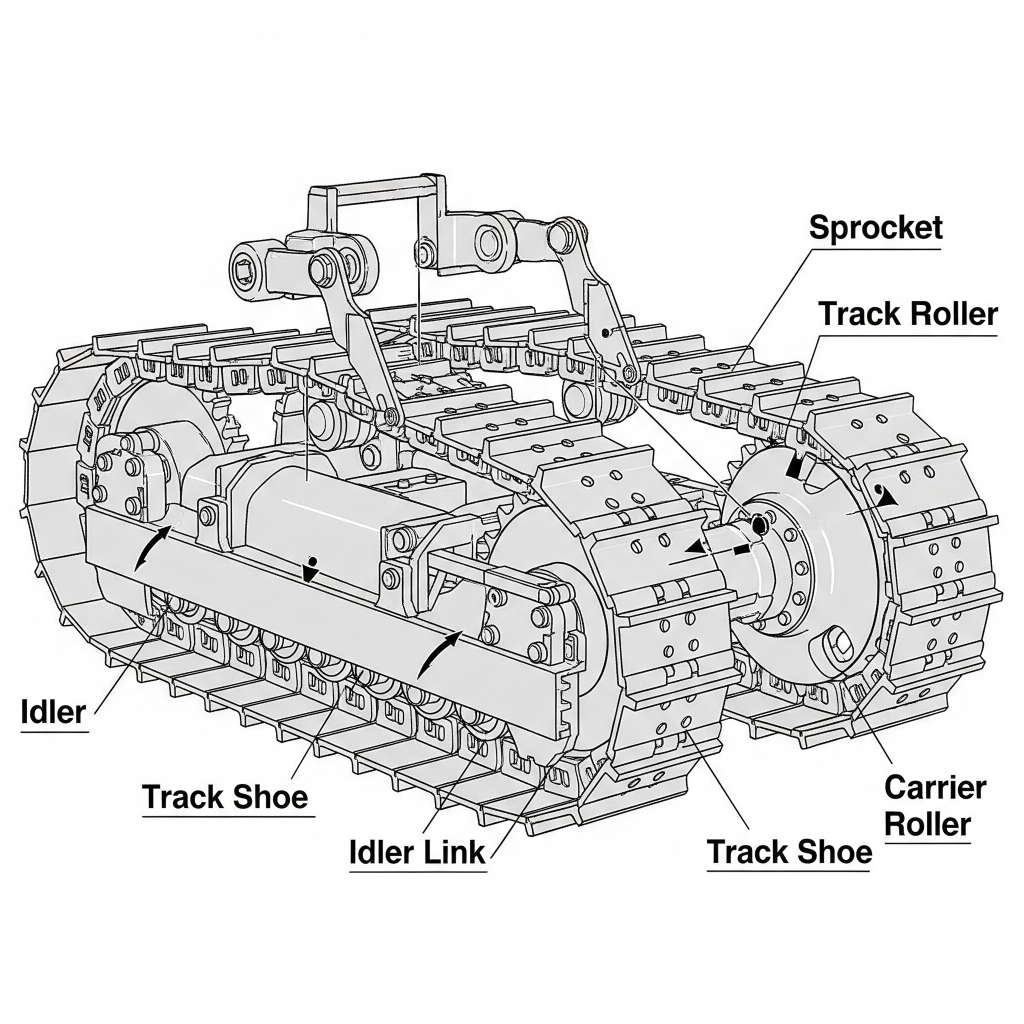

Think of your bulldozer's undercarriage as its foundation. Each part works in a system, and the failure of one accelerates the wear of others. Understanding the function of these core undercarriage parts for bulldozers is the first step. They are the 'moving parts' that carry the entire weight of your machine and transfer its power to the ground.

Your complete track group is a complex system of interlocking components. From the track links and pins that form the chain to the rollers that carry the load, everything must work in perfect harmony. A mismatch in quality or wear level between, for example, a new track chain and old sprockets can lead to premature failure and costly, unscheduled downtime for your entire operation.

Key Undercarriage Components Explained

Here’s a simple breakdown of the main components and what they do. Knowing this helps you diagnose problems faster. For instance, "scalloping" on your track rollers often points to an issue with the track chain pitch, not necessarily a fault in the roller itself. This knowledge is crucial for cost-effective maintenance.

| Component | Primary Function | Also Known As | What Wear Looks Like for You |

|---|---|---|---|

| Track Chain | Forms the 'rail' the dozer runs on | Track Link Assembly | Chain "stretching" (pitch elongation), causing jumpy movement. |

| Track Roller | Bears the machine's weight onto the chain | Bottom Roller | Flattened or grooved surfaces (scalloping), leading to a rough ride. |

| Carrier Roller | Supports the track's weight on the top side | Top Roller | Seizing or developing flat spots, causing the chain to sag and slap. |

| Sprocket | Engages with and drives the track chain | Drive Gear, Segment | Teeth wearing into a "hooked" shape, which rapidly wears out bushings. |

| Idler | Guides the track chain at the front and maintains tension | Guide Wheel | Worn-out tread surface, leading to the track "walking off." |

Practical Tips from the Field

- Asymmetrical Wear is Real: Most operators have a dominant turning direction. This means one side of the undercarriage can wear 20-35% faster. To balance this, have your maintenance team rotate the entire track chains from left to right at mid-life.

- Match Components: Use the "replace as a set" rule. Never install new bushings with a worn, hooked sprocket. The mismatched geometry will destroy your new parts in record time.

- Measure, Don't Guess: Proactively measure pin/bushing wear and roller diameter monthly. This prevents "surprise" failures that bring your whole site to a halt.

Actual Case Study: A quarry operation noticed their D8 dozer's right-side undercarriage wore out 30% faster due to a consistent slope-grading pattern. By implementing a mid-life side-swap for their track group, they extended total undercarriage life from 4,000 to over 5,500 hours, saving thousands in parts and downtime.

OEM vs. Aftermarket Undercarriage Parts: Which Offers the Best Value for Your Fleet?

The real difference isn't the brand name; it's the metallurgy and manufacturing precision. High-quality aftermarket undercarriage parts for bulldozers can offer superior value by matching OEM specs without the brand markup. The secret lies in the heat treatment depth (case depth) and pitch tolerance, factors that determine if a part will last or fail prematurely.

For example, many low-cost aftermarket sprockets have only a 2-3mm hardened surface. Once that thin layer wears off, the soft core metal fails rapidly. In contrast, premium aftermarket and OEM parts for a Cat D9 feature deep induction hardening (up to 8mm), allowing them to withstand harsh conditions and even be re-profiled. This hidden quality is what separates a good investment from a costly mistake.

Hidden Factors That Determine True Value

Don't just look at the price tag. The pitch tolerance—the exact distance between track pins—is critical. Poorly controlled pitch on a cheaper track chain causes rollers to "climb" the bushings instead of meshing correctly. This creates a vibration and scalloping effect that destroys both the new chain and your existing rollers, multiplying your costs.

| Factor | Low-Cost Aftermarket | Premium Aftermarket / OEM | What This Means for Your Uptime |

|---|---|---|---|

| Case Hardness Depth | Shallow (2-3mm) | Deep (6-8mm+) | Deep hardening resists wear far longer, especially on machines over 35 tons. |

| Steel Toughness | Often brittle (high hardness, low toughness) | Balanced for toughness and hardness | Resists cracking and spalling from rock impacts, which is common in demolition. |

| Pitch Tolerance | Loose (±0.5mm or more) | Tight (±0.25mm) | Precise fit ensures smooth operation and prevents premature wear on rollers and sprockets. |

Practical Advice for Buyers

- For High-Impact Jobs: If you're working in a rock quarry, prioritize toughness over pure hardness. A slightly softer but tougher roller will resist cracking from repeated impacts far better than an overly brittle one.

- For Large Dozers (>35 tons): Never compromise on case depth. The high-stress environment will expose shallow-hardened parts quickly, and the resulting downtime cost will dwarf any initial savings.

- Ask Your Supplier for Specs: A reliable supplier can provide you with technical data on case depth and material composition. If they can't, it's a red flag.

Expert Insight: We've seen fleets save 30% upfront on cheap rollers, only to face a 200% cost increase from unscheduled downtime and collateral damage to their track chains within 6 months. Quality is the most effective cost-reduction strategy.

How Can Proper Operation and Maintenance Drastically Extend Undercarriage Life?

The single biggest factor in undercarriage life isn't the steel—it's the operator. We have documented cases where training operators in gentle turning and reversing habits extended the life of undercarriage parts for bulldozers by up to 40%. Aggressive habits like power turns or high-speed reverse on gravel act like a grinder on your investment.

Simple operational changes create massive savings. For instance, in muddy conditions, daily pressure washing is often a losing battle. A smarter field hack is to train operators to slightly loosen track tension. This allows the track assembly to "self-fling" abrasive mud during operation, which can extend bushing life by over 20% by preventing the mud from acting like a grinding paste.

Operator Habits That Save Money

- Avoid Aggressive Turns: Wide, gradual turns are much gentler on track links and rollers than sharp, pivot turns.

- Limit High-Speed Reverse: Reverse operation causes more wear on bushings and sprockets than forward motion. Reduce time and speed in reverse whenever possible.

- Alternate Turning Directions: If the job site allows, consciously alternate turning left and right to balance wear across the undercarriage.

- Work Up and Down Slopes: Avoid constant operation along the side of a slope, as it puts continuous high load on one side's rollers and track links.

Fleet Management Tip: Some major mining companies now use telematics to monitor operator behavior like turn radius and reverse speed. They tie operator bonuses directly to undercarriage wear metrics, reinforcing how critical skillful operation is to profitability.

What Should You Look For in a Reliable Undercarriage Parts Supplier?

Your supplier is more than a vendor; they are a partner in your fleet's uptime. A reliable supplier of undercarriage parts for bulldozers provides more than just components—they offer expertise, quality assurance, and a commitment to your success. They understand that a $2,000 part failure can easily halt a $20,000/day operation.

Look beyond the price and evaluate their entire system. Do they have robust certifications like ISO9001 and SGS? Do they perform 100% pre-shipment inspections? A supplier who invests in quality control is investing in your reliability. With over 20 years of specialized manufacturing experience, we know that consistent quality prevents the most expensive problem: unexpected downtime.

Supplier Checklist: 5 Must-Haves

- Proven Expertise: Look for a specialist with decades of experience in undercarriage parts, not a generalist. They should understand the difference between wear in sandy soil versus rock.

- Verifiable Certifications: ISO9001 (quality management) and SGS (third-party inspection) are strong indicators of a professional operation.

- Comprehensive Quality Control: Ask about their inspection process. 100% final inspection is the gold standard to ensure you get what you paid for.

- OEM Experience: A supplier that provides OEM services to well-known brands has already met the industry's highest standards for quality and consistency.

- Technical Support: Can they help you select the right track shoe width for your specific ground conditions or diagnose a strange wear pattern? True partners provide solutions, not just parts.

Frequently Asked Questions (FAQ)

How often should I inspect my bulldozer's undercarriage?

Daily visual checks for loose bolts or leaks are essential. We recommend a detailed measurement of key wear points like pins, bushings, and roller diameters monthly, especially in high-abrasion environments. This proactive approach prevents "surprise" failures.

Is it always cheaper to rebuild undercarriage parts than to replace them?

Not always. While turning pins and bushings can be cost-effective, it's wasted money if your sprocket teeth are already worn into a hooked profile. The geometric mismatch will cause accelerated wear on your "rebuilt" chain. Always inspect matching components before rebuilding.

Can the wrong track shoe width really increase wear?

Yes, significantly. Wider "swamp" shoes are great for flotation but increase turning resistance on hard or rocky ground. This puts extra stress and side-load on track links and pins, leading to faster wear. Always match shoe width to your primary ground conditions.

What is "packing," and how does it destroy undercarriage parts?

Packing happens when materials like mud, clay, or fine sand get compressed between undercarriage components (e.g., around rollers and sprockets). This abrasive paste dramatically accelerates wear and can even break seals, leading to lubrication failure. Proper track tension and cleaning are key to prevention.

Summary and Final Recommendations

Maximizing the life of your undercarriage parts for bulldozers comes down to a simple formula: select the right parts for the job, operate with skill, and partner with a reliable supplier. Remember that downtime is your biggest enemy, and quality components are your best defense. Focus on the hidden factors like metallurgy and manufacturing precision, not just the initial price tag, to achieve the lowest total cost of ownership.

Ready to improve your fleet's performance? Start by evaluating your operators' habits and your current parts' wear patterns. For your next replacement, choose a supplier who can provide both high-quality, certified parts and the expert advice you need. This proactive approach will keep your bulldozers productive and your projects profitable.

About Dingtai Engineering's Undercarriage Parts for Bulldozers

With over 20 years of focused experience, we at Dingtai Engineering specialize in manufacturing high-performance undercarriage parts for bulldozers and excavators. Our ISO9001 & SGS certified facility and team of 20+ technical experts are dedicated to producing components that meet or exceed OEM standards. We serve as an OEM supplier for numerous global brands and provide the aftermarket with parts you can trust, backed by a 100% pre-shipment inspection.

Need a reliable parts solution for your fleet? Contact our experts on WhatsApp or email us for a consultation or a free quote on your specific model.

Last Updated: January 2025