I know how much it hurts your wallet when a machine sits idle on a job site because a track snapped or a roller seized. Every hour of downtime is a direct hit to your profit.

Upgrading your mini excavator with premium undercarriage parts like grease-sealed chains and forged rollers improves uptime by reducing friction and wear. Quality components ensure better fitment, longer service intervals, and higher stability, directly lowering your long-term operating costs and preventing unexpected job site failures.

If you are tired of replacing the same parts every season, it is time to look at why quality matters. Let's dive into the technical upgrades that actually keep your machine moving.

How much can I improve my machine's uptime by switching to premium grease-sealed track chains?

Are you tired of dealing with "track snake" or stiff links that make your excavator feel sluggish and difficult to maneuver on tight job sites? It is a common sign of internal wear.

Switching to premium grease-sealed track chains can improve machine uptime by 20% to 30% because they reduce internal pin and bushing wear. These chains use high-quality seals to keep lubrication in and abrasives out, significantly extending the life of the entire undercarriage system.

When I talk to fleet managers, the biggest concern is always how long a part lasts before it stretches. In a standard dry chain, metal rubs against metal every time the track moves. This creates heat and grinds down the pins. By using a grease-sealed track chain 1 design, we put a protective layer of lubrication inside each joint. This layer stays there for the life of the chain, preventing the "stretching" that leads to track derailment 2.

At Dingtai, we ensure our chains are made from high-strength steel that matches the original specs of brands like Komatsu 3 or Caterpillar 4. This means the pitch remains consistent, which also protects your expensive drive sprockets 5 from wearing out prematurely.

Comparison of Track Chain Types

| Feature | Standard Dry Chain | Premium Grease-Sealed Chain |

|---|---|---|

| Internal Lubrication | None (Metal-on-metal) | Factory-sealed grease |

| Wear Life | Short to moderate | 25-40% longer service life |

| Noise Level | High (Clanking) | Low (Smoother operation) |

| Adjustment Need | Frequent | Minimal |

Chain Material Specifications

- Material: 40Mn2 or 50Mn high-carbon steel.

- Hardness: Surface hardness of HRC 52-58 for maximum wear resistance.

- Seal Type: Polyurethane seals to prevent oil leakage and dirt entry.

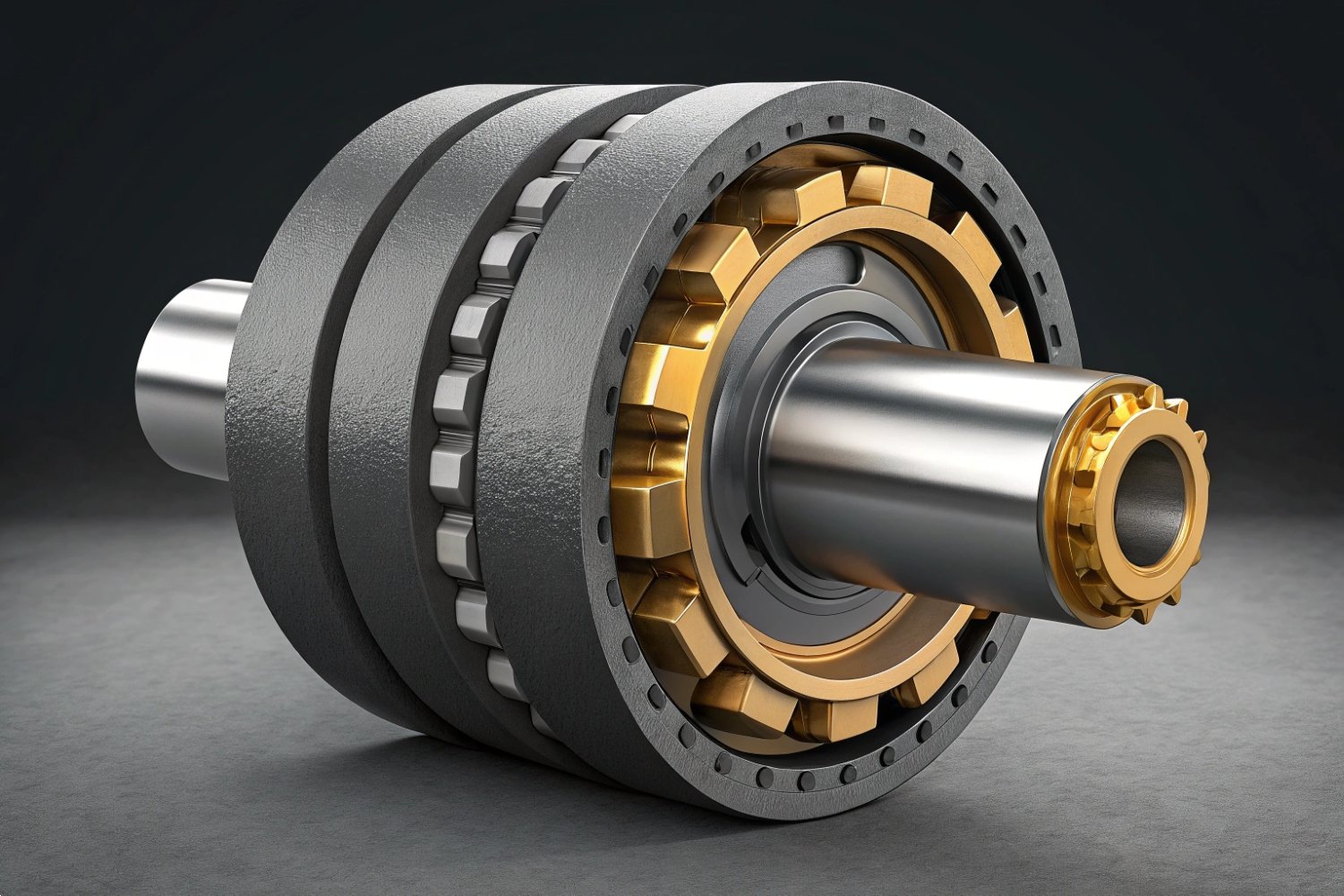

What technical improvements in roller seal technology should I look for to extend my service intervals?

Do you find yourself constantly checking for oil leaks around your rollers, or worse, finding rollers that have completely stopped turning? Seal failure is the leading cause of roller death.

Look for heavy-duty metal face seals (often called Duo-Cone seals) and forged boron steel construction. These improvements prevent oil leaks and protect internal components from grit, allowing you to double your service intervals compared to using standard, low-grade aftermarket rollers.

I always explain to my customers that a roller is only as good as its seal. Once dirt gets past the seal, it acts like sandpaper on the bearings. We use "mirror-finish" metal face seals 6 that fit together so tightly that even microscopic dust cannot get in. Additionally, we use forged boron steel 7 for the roller shells. Forging makes the metal much denser than casting, which means it can handle the heavy pounding of a 5-ton or 8-ton machine without cracking.

Our induction hardening 8 process also creates a deep "wear zone." While some cheap parts only have a thin skin of hardness, our rollers are hardened deep into the metal. This ensures that even after months of working in abrasive sand or mud, the roller maintains its shape and support.

Roller Performance Metrics

| Component | Standard Roller | Dingtai Premium Roller |

|---|---|---|

| Seal Design | Standard Rubber O-ring | Mirror-Finish Metal Face Seal |

| Shell Process | Cast Steel | Forged Boron Steel |

| Hardness Depth | 2mm - 3mm | 3mm - 5mm (Induction Hardened) |

| Oil Type | Basic Lubricant | Specialized High-Temp Gear Oil |

How do I transition my mini excavator from standard to wide tracks without affecting the undercarriage geometry?

Are you working on soft landscapes or wet soil where your machine keeps sinking, leaving deep ruts that cost you extra time and money to repair?

To transition to wide tracks safely, you must ensure the new track pitch matches your drive sprocket exactly and check that the increased width does not interfere with the frame or rollers. Using wide tracks with specialized tread patterns provides better flotation without putting excessive side-load on your final drives.

Many of my clients want to move from standard steel tracks to wider rubber tracks or hybrid systems. The goal is to lower the "ground pressure 9." However, if you simply put wider shoes on a standard frame without checking the alignment, you can cause the rollers to wear unevenly on one side. I recommend checking the "guide clearance" on your idlers to ensure the wider track stays centered during sharp turns.

We often suggest "hybrid" track systems for mini excavators. These use a steel chain with bolt-on rubber pads. This gives you the incredible strength of steel for climbing over curbs, but the wide, soft footprint of rubber to protect the grass. It is the ultimate upgrade for contractors who do both demolition and landscaping.

Track Selection by Working Condition

| Surface Type | Recommended Track | Benefit |

|---|---|---|

| Hard Rock/Demo | Standard Steel | Maximum puncture resistance |

| Soft Dirt/Grass | Wide Rubber | Low ground pressure; no turf damage |

| Mixed Surfaces | Hybrid (Steel + Pad) | High durability with surface protection |

Why is sourcing from an ISO-certified manufacturer like Dingtai safer than buying generic aftermarket parts?

Have you ever saved a few dollars on a part only to have it fail in a week, leaving you with a broken machine and a frustrated customer? Cheap parts are often the most expensive choice.

Sourcing from an ISO-certified manufacturer ensures that every part follows a strict quality control process, from raw material selection to final heat treatment. Certification like ISO9001 means you get consistent performance, verified material reports, and a professional warranty that generic suppliers simply cannot provide.

In my 20 years of manufacturing, I have seen why certification matters. It isn't just a piece of paper; it is a promise of consistency. Generic suppliers often change their steel sources to save money, leading to parts that are brittle or too soft. At Dingtai, we test every batch. We check the chemical composition of the steel and the depth of the heat treatment.

For a buyer like David, who manages a large inventory, consistency is key. He needs to know that the 100th roller he buys is just as good as the first one. By dealing directly with a factory that handles R&D and production, you get a direct line to technical support. If you have a specific technical question about fitment for an old Hitachi or a new Bobcat 10, our engineers can give you the answer immediately.

The Value of ISO-Certified Sourcing

- 100% Inspection: Every part is checked for dimensions and hardness before shipping.

- Material Reports: We can provide technical data sheets for all steel components.

- Warranty Security: We stand behind our products because we control the entire making process.

Conclusion

Upgrading your mini excavator requires focus on quality materials, precise fitment, and verified manufacturing standards to ensure long-term reliability and maximum profit.

Footnotes

1. Technical benefits of grease-sealed chains for heavy machinery tracks. ↩︎

2. Common causes and prevention of excavator track derailment. ↩︎

3. Official specifications for Komatsu construction equipment undercarriages. ↩︎

4. Resource for Caterpillar mini excavator parts and maintenance. ↩︎

5. Identifying wear patterns in heavy equipment drive sprockets. ↩︎

6. Engineering guide to high-performance metal face seals. ↩︎

7. Properties of boron steel in high-impact industrial applications. ↩︎

8. Explanation of the induction hardening process for metal durability. ↩︎

9. Calculating ground pressure for tracked construction equipment. ↩︎

10. Maintenance standards for Bobcat compact excavators and loaders. ↩︎