I know the frustration of seeing my Cat dozer sit idle because a track chain snapped or a roller seized. These repairs cost me a lot of money and stop my work completely.

To keep your Cat dozer undercarriage in good shape, follow a proactive, daily inspection and cleaning routine, ensure proper track tension, and use manufacturer-recommended maintenance intervals for fluids, filters, and lubrication.

I have learned that taking a few minutes every day to check the machine saves me from massive bills later. It is all about catching the small problems before they turn into disasters that break my budget.

How do I measure the "track sag" on my Cat dozer to prevent excessive tension on my sprockets?

I used to think tighter tracks were better, but I was wrong. Tight tracks wear out my sprockets and bushings much faster than they should, so I had to learn the right way to measure sag.

Measuring track sag involves finding the distance between the top of the track and the top of the carrier roller or frame. Correct sag prevents excessive tension, which reduces friction and heat on your sprockets and links.

Measuring track sag is a simple task that I do right on the job site. First, I move my dozer forward slowly and let it coast to a stop. This makes sure the track is tight between the sprocket and the front idler. I then take a straight edge or a string and lay it across the top of the track. I measure the distance from the string down to the lowest point of the track between the rollers. This distance is what we call the "sag."

If the track is too tight, it puts a huge amount of pressure on the bushings and sprocket teeth 1. This friction generates heat. Heat is the enemy of metal. It makes the parts soft and causes them to wear away like butter. On the other hand, if the track is too loose, it might jump off the idler. This causes "thrown tracks" which are a nightmare to fix in the mud. I always check my manual for the exact measurement. For most Cat dozers, I look for about two inches of sag.

I also have to think about the ground I am working on. If I am in thick mud, the mud packs into the links. This makes the track tighter. In these cases, I actually loosen the track a bit more than usual. This extra space allows the mud to squeeze out 2 without stretching my chain.

Track Tension Adjustment Guide

| Ground Condition | Recommended Sag | Why? |

|---|---|---|

| Hard Rock / Gravel | Factory Standard | Prevents impact damage and keeps links stable. |

| Loose Dirt / Sand | Slightly Loose | Allows material to fall out easily. |

| Wet Mud / Clay | Extra Loose | Prevents "packing" from over-tightening the chain. |

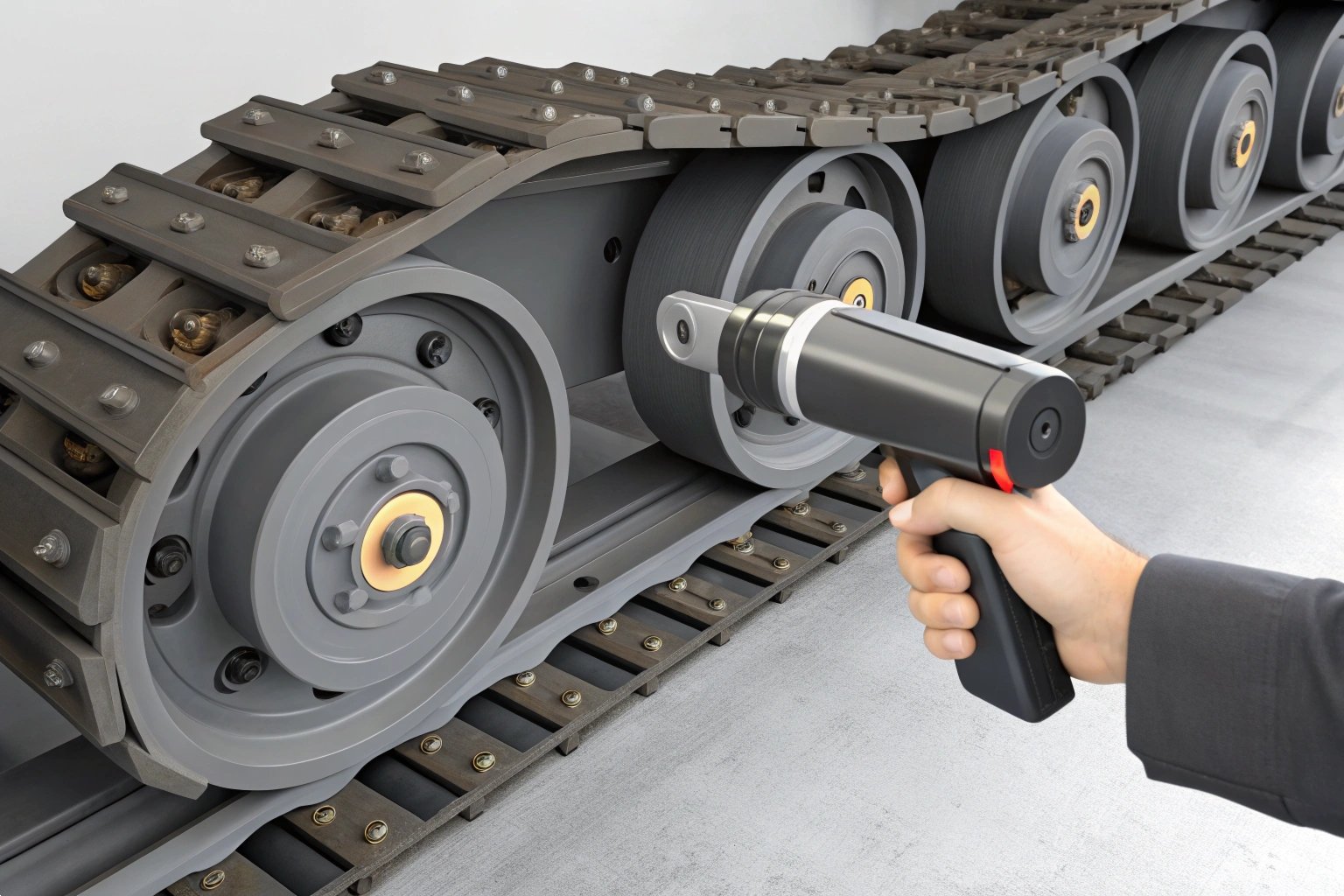

I keep a grease gun handy to adjust the tension. My Cat dozer has a hydraulic adjuster 3. I just pump grease in to tighten it or bleed a little out to loosen it. It is a five-minute job that adds hundreds of hours to my parts' life.

What is the best procedure for me to inspect the oil levels in my Cat dozer's lifetime-lubricated rollers?

I used to worry that "lifetime-lubricated" meant I never had to look at my rollers, but that is a dangerous mistake. If the oil leaks out, the roller will burn up and stop turning.

The best procedure is to perform a visual check for "weeping" seals and use an infrared thermometer to check for hot spots. If a roller is significantly hotter than others, it likely has low oil levels or internal damage.

Most modern Cat rollers are sealed units. You cannot simply pull a dipstick to check the oil. Instead, I use my eyes and ears. Every morning, I walk around my machine. I look at the seals on the side of each roller. If I see dark, oily dirt sticking to the seal, I know I have a leak. This "weeping" is the first sign of trouble. If I ignore it, the oil will run dry, and the metal bearings inside will start grinding against each other.

Another trick I use is an infrared thermometer 4. After working the dozer for a few hours, I jump out and point the laser at each roller. They should all be roughly the same temperature. If I find one roller that is 20 or 30 degrees hotter than the rest, I know the oil is gone. That roller is working too hard and is about to fail. I also listen for "squealers." If a roller makes a high-pitched noise while the machine is moving, it is crying for help.

I also check for flat spots. If a roller gets stuck because of mud or bad bearings, the track will slide over it. This wears a flat spot into the roller. Once a roller has a flat spot, it will never turn smoothly again. It will vibrate and damage the track links 5. I make sure to clean the mud out every night so the rollers can spin freely the next morning.

Common Roller Issues and Solutions

| Symptom | Probable Cause | Action Needed |

|---|---|---|

| Leaking Seal | Seal failure or debris wrap | Replace seal or complete roller immediately. |

| High Temperature | Lack of lubrication | Replace roller before it seizes. |

| Flat Spots | Roller was stuck/frozen | Replace roller and check for debris. |

| Side Wear | Machine misalignment | Check idler alignment and guide guards. |

I always tell my team that a $200 roller is much cheaper than a $5,000 track chain repair. If we see a bad roller, we change it right away. We don't wait for it to break the whole system.

How can I prevent "dry joints" in my Cat dozer's track chains through proactive maintenance?

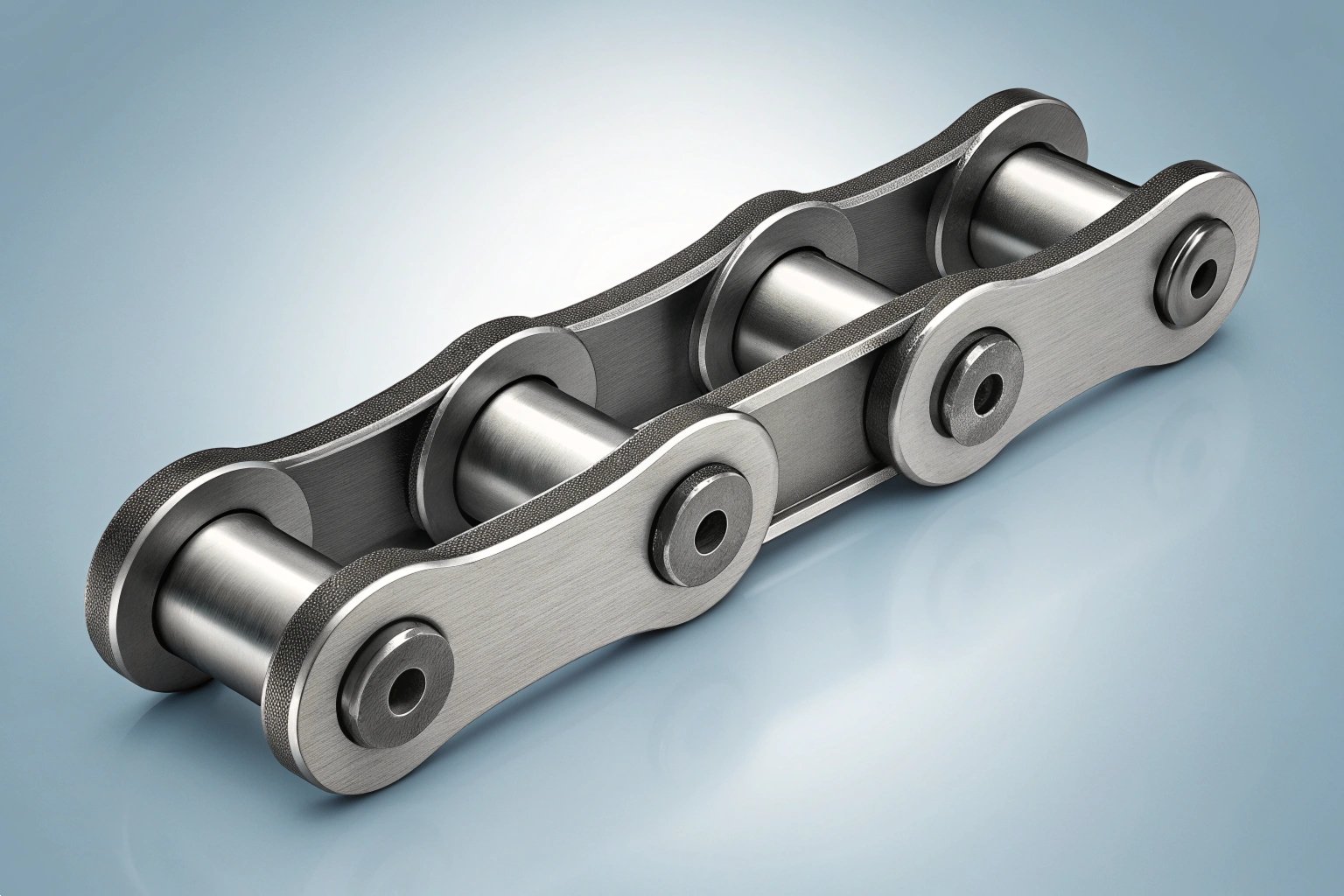

Dry joints are a silent killer for my track chains. When the factory grease inside the pin and bushing leaks out, the metal rubs together. This creates "internal wear" that makes the whole chain get longer.

To prevent dry joints, you must minimize high-speed travel, avoid excessive reverse operation, and conduct "wet turns" or pin-and-bushing rotations before the wear limit is reached to extend the chain's life.

Preventing dry joints starts with how I drive the machine. I noticed that when my operators drive fast in reverse 6, the tracks wear out twice as fast. Reverse travel puts more stress on the side of the bushings. This heat can damage the seals that keep the grease inside. I always tell my guys to take wide turns. Sharp, "pivot" turns grind the links and put sideways pressure on the pins. This pressure opens up small gaps in the seals, letting the grease out and the dirt in.

Once the grease is gone, the pin starts eating the bushing from the inside. This is called "pitch extension" 7. It makes the track feel loose even if the shoes look fine. I use a ruler to measure the distance across four or five links. If the distance is longer than the factory spec, I have internal wear. This is when I consider a "pin and bushing turn" 8. We take the chain to a shop, press out the pins, and rotate the bushings 180 degrees. This gives the chain a brand-new wearing surface without buying a whole new chain.

I also pay attention to where I park. In the winter, mud can freeze around the links. When I start the machine in the morning, the frozen mud acts like a wedge. It can pop the seals right off the pins. I try to park on wooden planks or dry ground to keep the tracks from freezing to the earth. It sounds like a small thing, but it saves my "wet" joints from becoming "dry" ones.

Track Chain Maintenance Schedule

| Interval | Task | Why? |

|---|---|---|

| Daily | Visual check for "kinked" links | Identifies seized joints early. |

| Weekly | Measure track pitch | Tracks internal wear of pins and bushings. |

| 1000 Hours | Ultrasonic wear test 9 | Gives a precise report on remaining life. |

| As Needed | Pin and Bushing Turn | Doubles the life of the chain at half the cost. |

I prefer buying high-quality chains with good seal technology. At Dingtai, we make sure our chains have 100% quality inspection because we know David Miller and people like him cannot afford a dry joint in the middle of a big job.

Why should I monitor the alignment of my dozer's idlers to prevent uneven wear on my track links?

If the idler is not straight, the track chain will try to climb the side of it. This creates "side wear" on my links and rollers. It is like having a car with a bad alignment; the tires wear out in weeks instead of years.

Monitoring idler alignment ensures the track chain runs centered over the rollers and sprockets. This prevents "link scalloping" and side-loading wear, which can destroy an undercarriage in half its expected lifespan.

I check the alignment of my idlers by looking at the wear patterns on the side of the track links. If I see that one side of the link is shiny and the other side is rusty, I know something is crooked. The idler's job is to guide the track. If the idler is tilted or shifted to one side, it pushes the entire chain out of line. This causes the rollers to rub against the "flanges" or edges of the links. This rubbing creates heat and shaves off metal every time the track goes around.

Correcting this usually involves looking at the "shims" 10 or wear strips on the idler frame. Over time, these plates wear down. When they get thin, the idler starts to wobble. I replace these wear strips as soon as I see more than a few millimeters of play. It is a cheap fix that protects the most expensive part of the machine. I also check the "guide guards." These are the metal plates that keep the track from sliding sideways. If they are worn out, the track has too much room to move, which leads to misalignment.

I have found that poor alignment also affects the drive sprocket. If the track is coming in at an angle, it will hit the side of the sprocket teeth. This "side-loading" can actually crack the sprocket segments or cause the track to jump teeth. I always make sure the idler is centered perfectly. I use a simple string line from the sprocket to the idler to see if they are in the same plane. If the string doesn't touch the center of every roller, I know I have an alignment problem that needs fixing.

I tell my customers that maintenance is not an expense; it is an investment. By keeping the idler aligned, I am making sure every dollar I spent on that track chain is used completely. I don't want to throw away a chain that still has 50% of its metal left just because the sides are chewed up by a crooked idler.

Conclusion

I have learned that maintaining my Cat dozer is about small, daily habits. Cleaning, checking tension, and watching for leaks keeps my machine running and my business profitable.

Footnotes

1. Expert advice on identifying wear patterns on bushings and sprockets for maintenance. ↩︎

2. Official Caterpillar tips for maintaining undercarriages and managing debris packing. ↩︎

3. Technical guide on how hydraulic track adjusters work to maintain proper tension. ↩︎

4. Field methods for using infrared thermometers to detect failing roller bearings. ↩︎

5. Comprehensive overview of undercarriage wear patterns and link damage causes. ↩︎

6. Discussion on how operating habits like reverse travel impact undercarriage longevity. ↩︎

7. Guide to measuring track pitch to determine internal pin and bushing wear. ↩︎

8. Explanation of the "pin and bushing turn" process to extend track life. ↩︎

9. Details on how ultrasonic testing provides accurate measurements of metal thickness and wear. ↩︎

10. Community insights on adjusting idler shims for proper track alignment on dozers. ↩︎