I have spent over two decades dealing with heavy machinery parts, and I know that choosing the wrong undercarriage components for a Cat machine is a nightmare that costs both time and trust.

To discover the importance of quality Cat undercarriage parts, you must look at the total cost of ownership, machine uptime, and the protection of expensive internal drive systems. Quality parts ensure 50% lower maintenance costs and prevent catastrophic failures in harsh environments.

Investing in high-grade steel and proper heat treatment is not just about the parts themselves; it is about keeping your entire project on schedule. Let me explain why these components are the literal foundation of your business success.

How do high-quality undercarriage parts protect my Cat machine's expensive final drives and motors?

I often tell my customers that the undercarriage is like the shoes of an athlete; if the shoes are bad, the knees and hips will eventually fail.

High-quality undercarriage parts protect final drives and motors by maintaining perfect alignment and reducing vibration. Precision-engineered links and rollers prevent excessive side-loading and shock waves from reaching the expensive gearbox and hydraulic motor, extending their service life significantly.

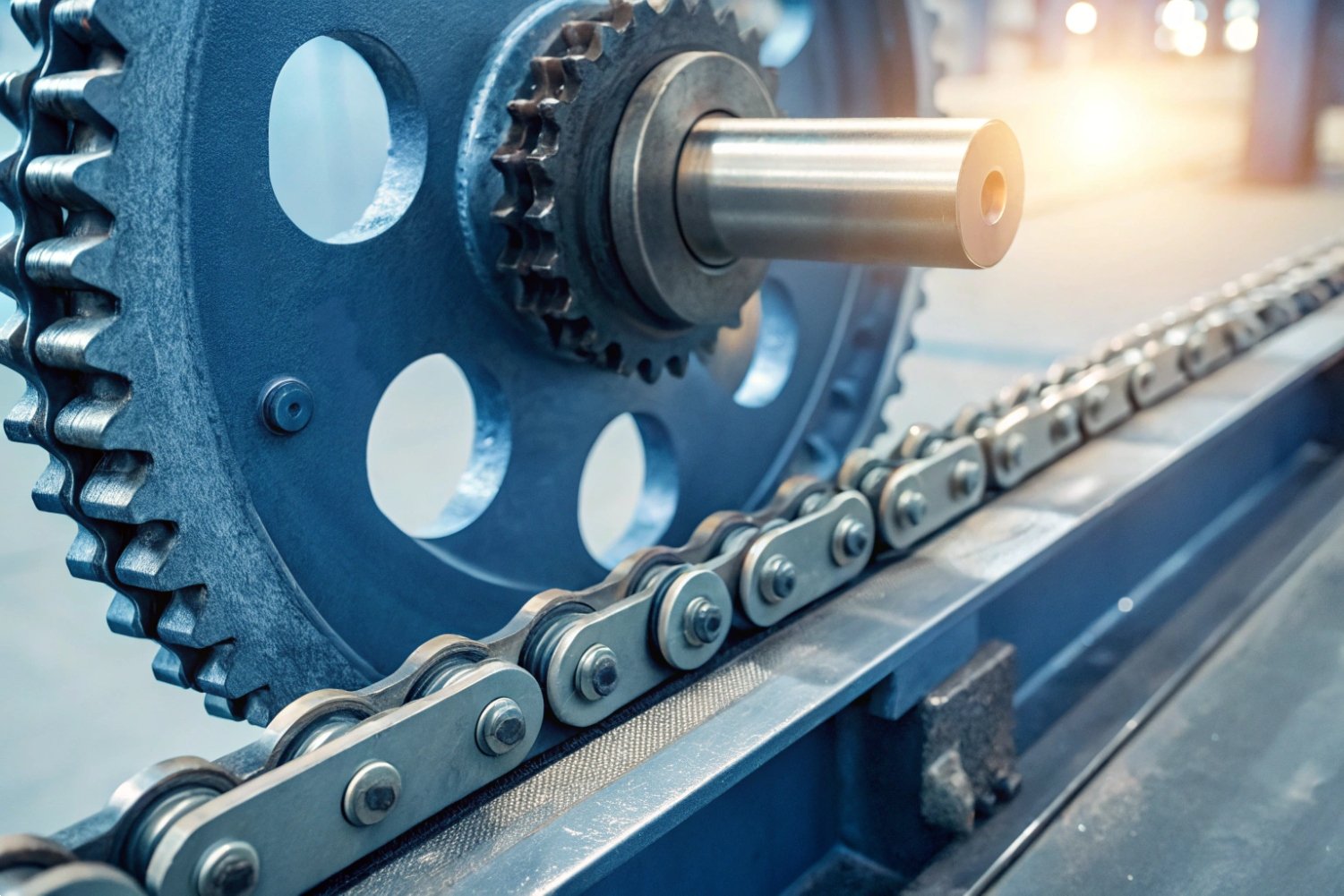

The Mechanical Link Between Tracks and Drives

When we talk about the undercarriage, we are talking about a complex system where every part affects the others. If you install low-quality track chains that have uneven pitch or poor hardening, they do not wrap around the sprocket 1 smoothly. This creates a "hunting" effect where the sprocket teeth struggle to find their seat. This vibration travels directly back into the final drive. I have seen many cases where a "cheap" track chain caused a $10,000 final drive failure 2 within just six months.

Vibration and Seal Integrity

Quality rollers and idlers are crucial for absorbing ground shocks. Cheap parts often have poor internal seals or low-grade oil, causing them to seize. A seized roller creates immense friction, which forces the travel motor to work harder, increasing heat and pressure. High-quality components use Duo-Cone seals 3 and superior lubrication to ensure they spin freely under any load, which keeps the operating temperature of your motors within a safe range.

Comparative Protection Levels

| Component | Impact of Low Quality on Drive | Benefit of High-Quality Dingtai Parts |

|---|---|---|

| Track Chain | High vibration, sprocket wear | Smooth engagement, less torque strain |

| Track Rollers | Increased rolling resistance | Reduced motor load, fuel savings |

| Sprockets | Poor mesh, chain jumping | Perfect pitch match, long gear life |

What is the impact of using non-compliant undercarriage parts on my Cat machine's resale value?

In my experience, a savvy buyer like David Miller will walk straight to the undercarriage and pull out a wear gauge 4 before even looking at the engine.

Non-compliant undercarriage parts drastically lower resale value because they signal poor maintenance habits to potential buyers. Machines with generic, mismatched, or heavily worn parts often sell for 20% to 30% less than those equipped with certified, high-quality components.

First Impressions and Technical Trust

When a machine hits the used market, the undercarriage represents about 50% of the remaining maintenance value. If I see non-compliant parts, I immediately worry about the "hidden" damage. Non-compliant parts often have different bolt patterns or slightly off-set clearances. This forces the machine frame to twist in ways it wasn't designed for. A buyer sees these parts and thinks about the future repair bills 5 they will have to pay, which gives them huge leverage to beat you down on the price.

Documentation and Traceability

Quality manufacturers provide material reports and heat-treatment data. When you can show a buyer that you used ISO 9001 6 certified parts from a reputable supplier like Dingtai, you are providing "proof of life" for the machine. Non-compliant parts usually lack any branding or serial numbers, making it impossible to know their history. In the B2B world, transparency is currency.

Value Retention Comparison

| Machine Age | Value with Premium Parts | Value with Generic Parts | Difference |

|---|---|---|---|

| 3 Years | 75% of Original | 60% of Original | 15% Loss |

| 5 Years | 55% of Original | 35% of Original | 20% Loss |

| 8 Years | 30% of Original | 15% of Original | 15% Loss |

How can I reduce my Cat fleet's cost-per-hour by investing in premium heat-treated components?

I always argue that the cheapest part you can buy is the one you only have to install once every three years instead of every six months.

You can reduce cost-per-hour by investing in premium heat-treated components that offer deeper hardness depth and superior wear resistance. These parts last twice as long as standard alternatives, meaning you save on both the purchase price and the high cost of labor and downtime.

Understanding Wear Life vs. Purchase Price

The biggest mistake I see in this industry is focusing on the "upfront" cost. Let's look at the math. If a cheap track link costs $100 but lasts 2,000 hours, your cost is $0.05 per hour. If a premium Dingtai link costs $150 but lasts 5,000 hours, your cost is $0.03 per hour. Over a fleet of ten machines, this difference adds up to tens of thousands of dollars. Premium heat treatment 7, such as induction hardening, ensures that the steel stays hard even as it wears down, maintaining its structural integrity.

Reducing Unplanned Downtime

Downtime is the silent profit killer. When a machine stops in a mine or a busy construction site, you aren't just losing the cost of the part; you are paying operators to sit idle and potentially facing penalties for late project completion. Premium parts are consistent. You can predict when they will need replacing. This allows you to schedule preventative maintenance 8 during planned breaks, rather than reacting to a catastrophic break in the middle of a shift.

The Math of Maintenance

| Expense Category | Generic Parts (Low Quality) | Premium Dingtai Parts |

|---|---|---|

| Initial Part Cost | $5,000 | $7,500 |

| Service Life | 1,500 Hours | 4,000 Hours |

| Labor Cost (2 changes) | $4,000 | $2,000 (1 change) |

| Total Cost Per Hour | $6.00 / hr | $2.37 / hr |

Why is material traceability essential for my Cat machine's safety in extreme mining or construction sites?

I have seen the aftermath of a track chain snapping on a steep incline, and it is a situation I never want my customers to face.

Material traceability is essential because it guarantees that every component meets the specific metallurgical standards required to handle extreme stress. In mining or rocky construction sites, traceable parts ensure there are no internal cracks or impurities that could lead to sudden, dangerous structural failure.

Safety in Harsh Environments

When a machine is working on a 30-degree slope in a mine, the undercarriage is under immense tension. If a single pin or bushing has a hidden defect—like a gas bubble in the casting or improper tempering—it can shatter without warning. Material traceability 9 means we know exactly which batch of steel was used, who forged it, and what the test results were. At Dingtai, we perform 100% quality inspection because we know that a part failure in the field is a safety hazard, not just a mechanical issue.

Accountability and Quality Control

Traceability creates a loop of accountability. If a part from a specific batch shows premature wear, we can trace it back to the exact production hour and correct the process. For a customer like David Miller, this level of detail provides peace of mind. He knows that the products he distributes are backed by data, not just promises. In extreme conditions, "good enough" is never enough. You need parts that are engineered to survive the toughest rocks and the coldest temperatures.

Traceability Checklist for Buyers

- Material Certification: Does the supplier provide a mill test report 10 for the raw steel?

- Heat Treatment Logs: Can they prove the depth of the hardening?

- Serial Numbering: Is there a way to identify the specific production run?

- Quality Certificates: Are they ISO9001 and SGS certified?

Conclusion

Choosing quality Cat undercarriage parts is the only way to ensure long-term profitability, machine safety, and high resale value. It saves money through lower cost-per-hour and protects your most expensive components.

Footnotes

1. Understand the critical role of sprockets in heavy machinery drive systems. ↩︎

2. Learn about the primary causes and high costs of excavator final drive failures. ↩︎

3. Discover how Duo-Cone seals protect internal components from harsh contaminants. ↩︎

4. A guide on using wear gauges to accurately measure undercarriage life. ↩︎

5. Insights into calculating and managing repair costs for heavy equipment. ↩︎

6. Official overview of ISO 9001 standards for quality management systems. ↩︎

7. Explore different heat treatment processes used to strengthen industrial steel. ↩︎

8. Best practices for implementing preventative maintenance in construction fleets. ↩︎

9. Why material traceability is vital for safety and quality in manufacturing. ↩︎

10. How to interpret a mill test report to verify steel quality and origin. ↩︎