Buying used Cat undercarriage parts feels like a gamble when you do not know what to look for. I have seen many buyers lose money on "cheap" deals that failed within weeks. You need a clear plan to spot real value.

Choosing used Cat undercarriage parts wisely means treating them like a high-value wear system: verify remaining life with measurements, inspect for abuse (not just wear), and buy only when the risk/price ratio makes sense for your fleet or resale goals.

If you are tired of getting burned by bad parts, keep reading. I will show you exactly how to measure wear and spot the red flags that most people miss.

How do I accurately measure the "remaining life" percentage on a used Cat track chain?

Measuring a track chain is the only way to know if you are getting a deal or buying scrap metal. I always carry a tape measure and a caliper because eyes can be easily fooled by a fresh coat of paint.

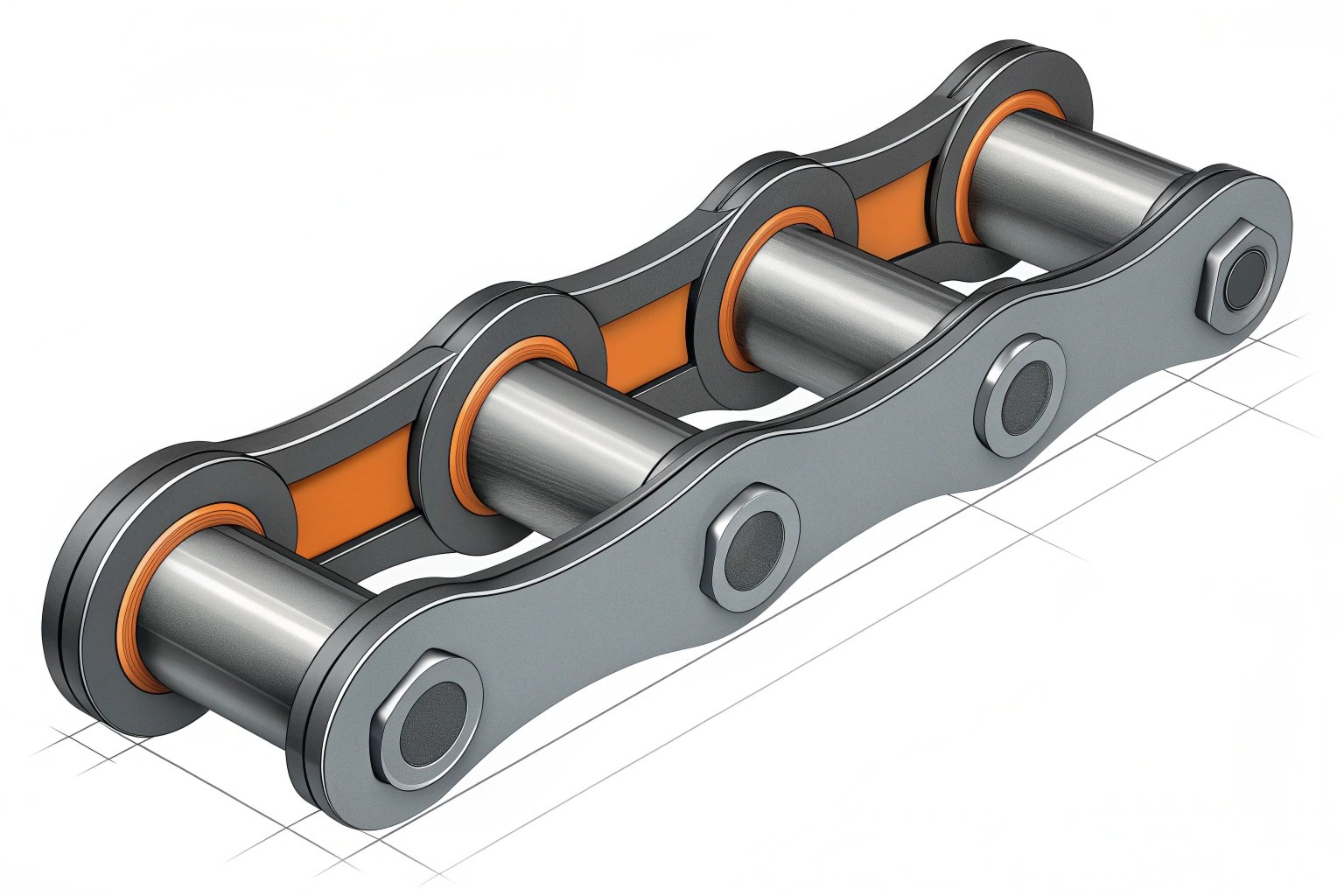

To measure remaining life, you must compare the current rail height and bushing diameter against the original factory specifications found in a Caterpillar Custom Track Service 1 handbook. A 120-inch span measurement across four pins reveals internal pitch wear and stretch.

When I look at a used chain, I start with the "External Wear." This means checking the height of the link rails. If the rails are worn down close to the pin bosses, the chain is almost finished. However, the biggest secret in our industry is "Internal Wear." This is the wear between the pin and the bushing. You measure this by pulling the chain tight and measuring the distance over several sections. If the chain has stretched significantly, it will not fit the sprocket teeth correctly, leading to fast destruction of both parts.

Another critical point is the bushing diameter. In a Sealed and Lubricated Track 2 (SALT), the oil inside should prevent internal wear. But once those seals fail, the wear accelerates. I always look for "dry joints." If a joint is stiff or making a clicking sound, the oil is gone. At that point, the "remaining life" drops to nearly zero, regardless of how thick the metal looks.

Common Measurement Points for Cat Chains

| Component | What to Measure | Tool Needed | Sign of High Wear |

|---|---|---|---|

| Link Rail | Top to bottom height | Caliper / Depth Gauge | Rail height is less than 75% of new |

| Bushing | Outer diameter | Caliper | Heavy "flat spots" or thinning |

| Track Pitch | Distance over 4 pins | Tape Measure | Chain is "stretched" beyond 2% of new length |

As a manufacturer at Dingtai, we see many customers trying to save money by mixing used chains with new sprockets. This is a mistake. If the used chain pitch is off, it will "climb" the new sprocket teeth and ruin them in days. Always ensure the wear levels are somewhat compatible.

What are the visual "red flags" I should look for when inspecting a used Cat idler or roller?

Visual inspection is your first line of defense. I have learned that if a part looks like it was abused, it probably was. You have to look past the dirt and grease to see the structural integrity of the steel.

Visual red flags include oil leaks around the duo-cone seals 3, "cupping" on the roller tread surface, and cracked flanges. For idlers, check the thickness of the center rim and look for any weld repairs that might hide deep structural cracks or fatigue.

When I inspect rollers, the first thing I do is try to spin them. A good roller should turn smoothly but with some resistance from the oil and seals. If it spins too freely, it might be dry. If it is seized, it is scrap. Look closely at the "flanges"—the edges that keep the track aligned. If they are thin or razor-sharp, the roller will eventually jump off the track. "Cupping" is another big issue. This is when the middle of the roller wears faster than the edges, creating a U-shape. This happens when the machine works in rocky terrain 4 or uneven ground for too long.

For idlers, I look at the "tread" surface. If the idler has been "sliding" instead of "rolling," you will see flat spots. This usually means the bearings inside have failed. I also check the brackets and shims. If an idler has been shimmed to the maximum limit, it means the entire undercarriage system is likely stretched to its limit. At Dingtai, we emphasize that 100% quality inspection is key, and used parts rarely pass the same standards as our factory-fresh components.

Roller and Idler Condition Checklist

| Red Flag | Problem Indicated | Severity |

|---|---|---|

| Wet Oil on Seal | Failed duo-cone seal | High (Internal failure imminent) |

| Flat Spots | Seized bearing | Critical (Do not buy) |

| Cracked Flange | Metal fatigue or impact | High (Safety risk) |

| Deep Pitting | Acidic soil or long-term rust | Medium (Reduced life) |

I tell my clients that if they see fresh welding marks on a used idler, they should walk away. Welding on heat-treated steel 5 often makes the metal brittle. It might look fixed, but it will crack again under the weight of a 20-ton excavator.

How can I verify if a used Cat undercarriage has been "run to destruction" or if it is a viable take-off?

The term "run to destruction" means the owner used the parts until they literally fell apart. A "take-off" is different; it usually comes from a machine that was upgraded or salvaged early. Distinguishing between them is the difference between a bargain and a disaster.

Verify viability by checking the slack adjuster 6 extension. If the front idler is pushed all the way forward, the chain is stretched to its limit. Also, check the sprocket teeth; if they are "knife-edged" or "hooked," the entire system was likely run until failure.

I always ask for the history of the donor machine. Was it a mining excavator 7 working 24/7, or a backup unit for a construction site? Mining parts are almost always run to destruction because downtime is so expensive. On the other hand, a "take-off" might come from a machine that was converted to a different track width or a different application.

One of my favorite tricks is to look at the track bolts. If the bolt heads are worn down flush with the track shoe, it is a sign of extreme use. Also, check the "grouser" height on the shoes. If the bars are level with the bolts, the shoes provide no traction. If someone is selling "viable" tracks but the shoes are bald, they are lying about the remaining life. At Dingtai, we provide full technical support to help buyers understand these nuances because a mismatched undercarriage can cause vibrations that damage the final drive 8 and engine mounts.

Comparing Take-offs vs. Run to Destruction

| Feature | Viable Take-off | Run to Destruction |

|---|---|---|

| Sprocket Teeth | Rounded or slightly flat | Pointy or "hooked" |

| Idler Position | Middle of the frame | All the way at the front |

| Pin/Bushing | Some paint or clean metal | Heavily rusted or "shiny" from friction |

| Seal Condition | Dry and intact | Oily or missing entirely |

It is also vital to check for "Symmetry." If the left side is 50% worn but the right side is 80% worn, the donor machine had undercarriage alignment 9 issues. Buying that set means your machine will likely pull to one side, causing even more wear on your steering and drive motors.

Why is it critical to check for internal bushing wear even if the external link looks good on used Cat parts?

This is the "silent killer" of undercarriages. A link can look thick and strong on the outside, but if the inside is hollowed out by friction, it will snap under load. I have seen perfect-looking tracks break in half because the buyer ignored the bushings.

Internal bushing wear determines the track pitch 10 of the track. Even if the links have 80% metal left, if the internal pins and bushings are worn, the track becomes "longer." This causes it to mismatch with the sprocket teeth, leading to massive friction, heat, and eventual breakage.

In a standard Cat SALT track, the pins are lubricated with oil. If a seal breaks, the oil leaks out, and dirt gets in. This creates a grinding paste that eats the metal from the inside out. You cannot see this with your eyes. You have to use a "Pitch Gauge" or measure the distance between pins. If you find "dry joints" (joints that are hot to the touch after the machine runs), the internal wear is extreme.

I often explain to my customers that buying a track with internal wear is like buying a car with a beautiful body but a broken engine. The links (the body) might look great, but the bushings (the engine) are what actually make the machine move. If the pitch is stretched, you will hear a "popping" sound as the track leaves the sprocket. That sound is the metal being torn away. At Dingtai, we use specialized heat treatment to make our bushings extra durable, which is why our new parts often outlast used "original" parts that were not maintained well.

Conclusion

Choosing used Cat undercarriage parts requires patience and a tape measure. Always prioritize measuring the remaining life over the price tag to ensure your machine stays productive and safe.

Footnotes

1. Comprehensive guide for measuring and managing wear life of Cat track systems. ↩︎

2. Technical overview of maintenance practices for sealed and lubricated track assemblies. ↩︎

3. Detailed specifications of mechanical face seals for heavy-duty construction equipment. ↩︎

4. Essential maintenance tips for equipment operating in high-abrasion environments. ↩︎

5. Engineering insights into the properties and structural benefits of heat-treated steel. ↩︎

6. Practical guide to monitoring and adjusting heavy equipment track tension. ↩︎

7. Product overview of high-capacity hydraulic mining shovels and their undercarriage needs. ↩︎

8. Detailed information on the operation and maintenance of track drive systems. ↩︎

9. Best practices for extending excavator life through proper alignment inspections. ↩︎

10. Industry discussion on calculating track pitch and understanding wear patterns. ↩︎