Finding the right parts for your mini excavator is a huge headache. If you pick the wrong ones, your machine stops, and your money just disappears into thin air every day.

Choosing the right undercarriage parts involves matching your specific machine model with your job site terrain. You must balance part durability, cost-effectiveness, and supplier reliability to ensure your equipment stays productive and your maintenance costs stay low over the long term.

I have spent years helping people like you find the best parts for your machines. It is not just about buying a part; it is about keeping your business running without stress. Let me share what I know so you can make the best choice for your fleet today.

How do I determine if a rubber track or steel track system is more cost-effective for my mini excavator's typical terrain?

Choosing between rubber and steel tracks is a hard choice that I see many owners struggle with every single month. You want to save money, but the wrong track can ruin your machine and your job site.

Rubber tracks are cost-effective for work on concrete or grass because they prevent surface damage and offer a smoother ride. Steel tracks are better for rocky or demolition sites where sharp objects would quickly destroy rubber, making them cheaper over time in harsh environments.

When I talk to customers like David, they often ask about the "real" cost. To figure this out, you have to look past the price tag. Rubber tracks 1 are great because they are quiet and do not tear up a customer's driveway. If you work in landscaping or urban areas, rubber is your best friend. It keeps your vibration low, which means your other machine parts last longer too. However, rubber does not like sharp rocks or rebar. If you take a rubber track into a demolition site, it might snap in a week. That is a very expensive mistake.

Steel tracks are much tougher. They can handle jagged rocks and heavy debris without any problems. If you are digging in a quarry or a rough forest, steel is the way to go. The downside is that steel is heavy and loud. It will also destroy any finished surface it touches. To help you compare, I made this simple table:

Track Material Comparison

| Feature | Rubber Tracks | Steel Tracks |

|---|---|---|

| Best Terrain | Grass, Asphalt, Concrete | Rock, Mud, Demolition |

| Surface Damage | Very Low | Very High |

| Operator Comfort | High (Smooth) | Low (Bumpy) |

| Durability | Moderate | Very High |

| Noise Level | Quiet | Loud |

I always tell my clients to look at their project list for the next six months. If 80% of your work is on dirt or grass, stick with rubber. But if you are moving into heavy construction, investing in a steel track system 2 now will save you thousands in replacement costs later. You also need to think about the weight. Steel tracks add more weight to your mini excavator. This gives you better traction, but it also uses more fuel. It is all about finding that balance for your specific needs.

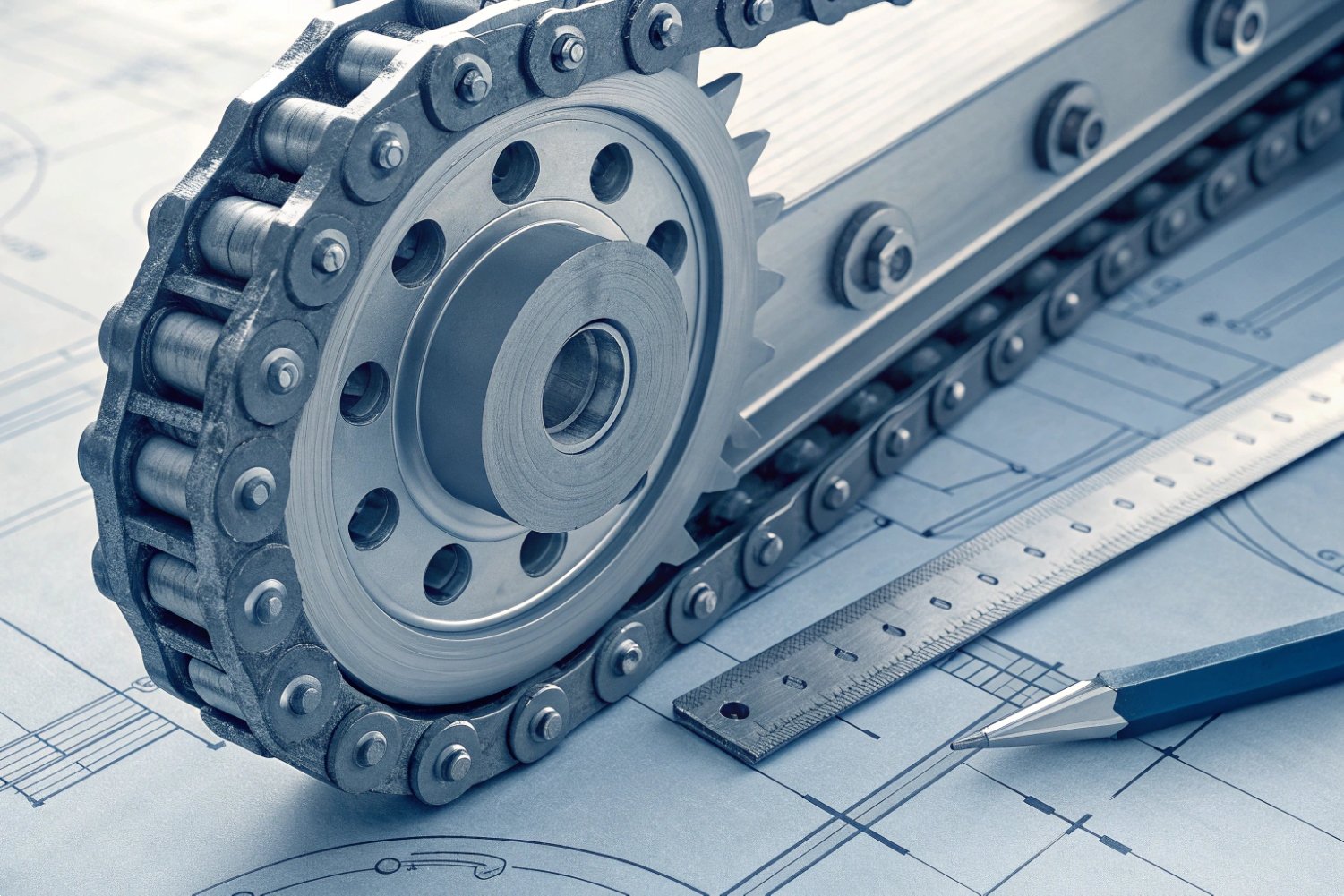

What measurements should I take to ensure the track pitch perfectly matches my mini excavator's drive motor?

Nothing is worse than buying a brand-new track and finding out the teeth don't line up with your drive motor. I have seen many people waste time and shipping costs because of a small measurement error.

To match your track pitch, you must measure the distance between the centers of two consecutive drive lugs or links. You also need to count the total number of links and measure the track width to ensure a perfect fit with your drive motor.

Measuring pitch sounds technical, but it is actually quite simple if you follow my steps. In my factory, we use very precise tools, but you can do this with a standard tape measure. First, find two lugs on your track. Measure from the middle of one lug to the middle of the next one. This distance is your "pitch." If this number is even a few millimeters off, the track will "jump" on the sprocket 3. This causes the metal to grind and will eventually break your drive motor, which is a very expensive fix.

You also need to check the width of the track. If the track is too wide, it might hit the frame of your excavator. If it is too narrow, the machine will feel unstable. I recommend checking the "link count" as well. This is simply the total number of metal bars or lugs in the entire loop of the track. Even if the pitch is right, the wrong link count means the track will be too loose or too tight.

Standard Measurement Guide

| Component | What to Measure | Why it Matters |

|---|---|---|

| Track Pitch | Distance between lug centers | Prevents sprocket wear |

| Track Width | Side to side of the track | Affects stability and clearance |

| Link Count | Total number of lugs | Ensures correct tension |

| Guide Width | Internal distance between lugs | Keeps track on the rollers |

Whenever you call a supplier, have these three numbers ready: Width x Pitch x Links. For example, a common size might be 300x52.5x80. If you give me those numbers, I can tell you exactly which part fits. Don't just rely on the machine model name, because sometimes manufacturers change the undercarriage design 4 in the middle of a production year. Taking two minutes to measure will save you two weeks of waiting for a replacement.

How can I verify the quality of the forged steel inserts inside my mini excavator's rubber tracks?

I have seen many cheap rubber tracks that look great on the outside but fail quickly because the steel inside is junk. You cannot see the steel, so how do you know if it is good? This is where many buyers get tricked.

You can verify quality by asking for material reports that show the use of forged steel rather than cast iron. Check if the steel cords are "continuous" rather than jointed, as continuous cords are much stronger and less likely to snap under pressure.

When I visit our production line at Dingtai, I always watch the steel forging process 5. Forging makes the steel much denser and stronger than casting. Imagine a piece of bread versus a piece of dense cake; the cake is much harder to pull apart. That is like forged steel. Cheap tracks often use cast iron inserts which are brittle. They can snap when you hit a curb or a large rock. Once the internal steel breaks, the rubber will soon follow, and the track will stretch or fall off.

Another big thing to look for is the "Continuous Steel Cord" technology. In the old days, the steel cables inside were looped and welded together at one point. That weld was a weak spot. Modern, high-quality tracks use a continuous steel cord 6 that wraps around many times. This distributes the tension evenly. When you talk to a supplier, ask them specifically: "Are these forged inserts or cast?" and "Are the steel cords continuous?" If they don't know the answer, they probably aren't the manufacturer.

Forged vs. Cast Steel Inserts

| Feature | Forged Steel (High Quality) | Cast Iron (Low Quality) |

|---|---|---|

| Strength | Very High | Brittle |

| Impact Resistance | Excellent | Poor (Cracks easily) |

| Weight | Consistent | Variable |

| Long-term Cost | Lower due to less breakage | Higher due to frequent failure |

I always provide my clients with a material report 7 if they ask. This report shows exactly what kind of steel we used and how hard it is. It gives you peace of mind. If a seller refuses to give you technical data, it is a red flag. You are buying a part that holds up a multi-ton machine; you deserve to know what is inside it.

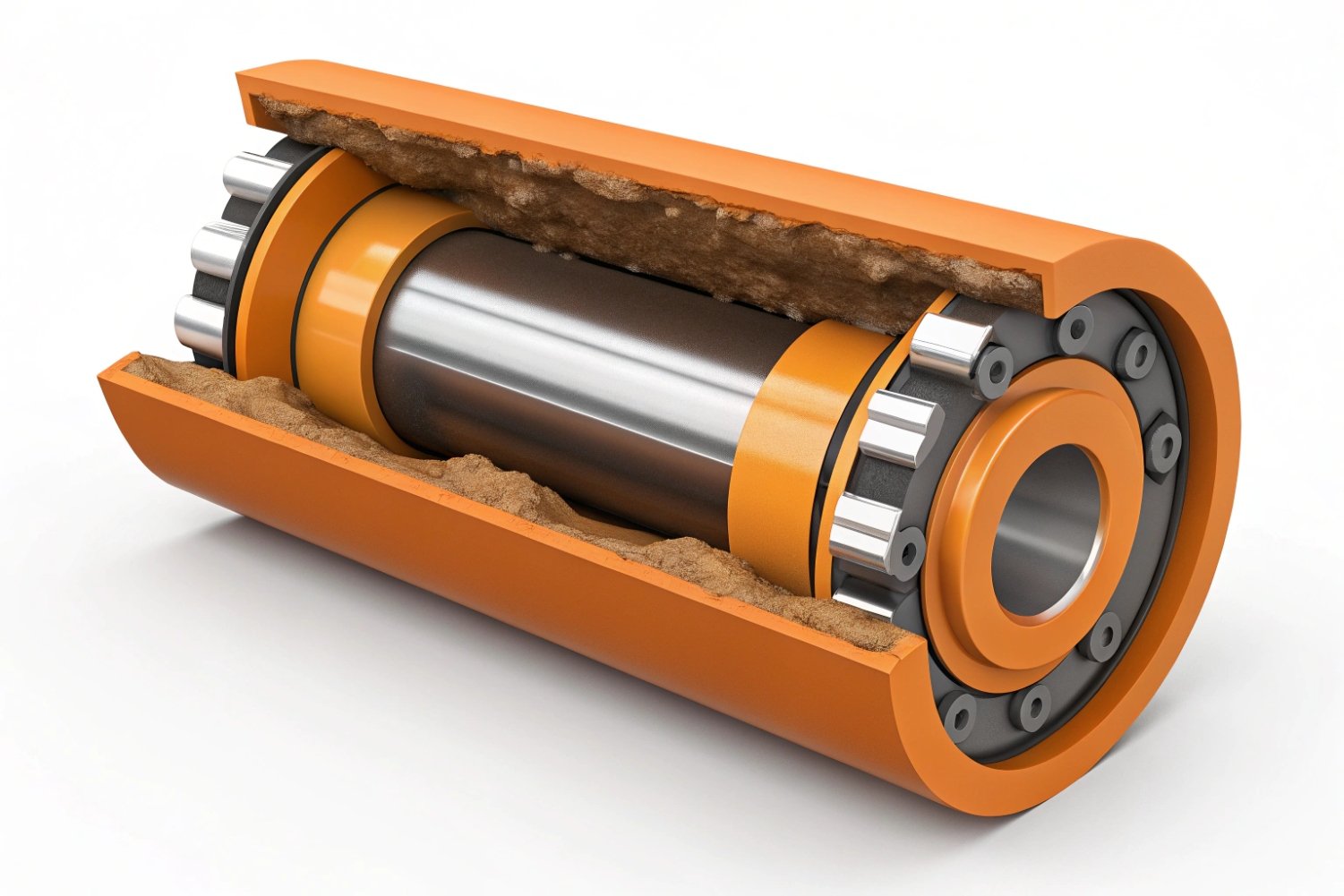

Why is the seal quality in my mini excavator's bottom rollers critical for preventing bearing failure in muddy conditions?

Mud is the silent killer of excavator undercarriages. I have seen hundreds of rollers seized up because a tiny bit of dirty water got inside. If your rollers don't spin, they start to wear down your track links, and soon you have a massive repair bill.

High-quality seals keep lubricating oil inside the roller and keep abrasive mud and water out. If a seal fails, the internal bearings lose lubrication and overheat, leading to a seized roller that can ruin your entire track system.

In my experience, the seal is the most important part of a roller. We use floating seals 8 which are designed to work in the worst conditions. Think of it like a protective barrier that stays tight even as the parts move and vibrate. When you work in mud, that mud tries to push its way into every gap. If the seal is made of cheap rubber, it will dry out, crack, or get pushed out of place. Once the mud gets in, it acts like sandpaper on the metal bearings.

I remember a customer who bought cheap rollers from a random website. Within three months, half of his rollers stopped turning. When we opened them up, they were full of dry mud. The bearings 9 were completely crushed. He had to replace not just the rollers, but also the track links that had been ground down by the frozen rollers. It was a very expensive lesson. That is why we do a 100% pressure test 10 on every roller we make at Dingtai to ensure the seals are perfect.

Roller Maintenance Checklist

- Daily Visual Check: Look for any oil leaking from the side of the roller.

- Temperature Test: After working, carefully feel if one roller is much hotter than the others.

- Rotation Check: Lift the machine and spin the tracks to see if all rollers move freely.

- Clean the Mud: Don't let thick mud dry on the rollers overnight; it puts extra pressure on the seals.

Investing in rollers with high-quality seals might cost 10% more today, but it will save you 100% of the cost of a new track later. Always look for rollers that mention "lifetime lubrication" and "heavy-duty floating seals." This shows the manufacturer cares about the parts of the roller you cannot see.

Conclusion

Choosing the right parts means checking compatibility, material quality, and seal technology. By following these steps, you protect your machine and your profit.

Footnotes

1. Explore the benefits and engineering behind high-performance rubber tracks for industrial machinery. ↩︎

2. Technical overview of steel track systems designed for extreme construction environments. ↩︎

3. Understanding the role of sprockets in maintaining undercarriage tension and efficiency. ↩︎

4. Guide to different undercarriage designs and their impact on machine performance. ↩︎

5. Deep dive into the steel forging process and why it produces stronger components. ↩︎

6. Benefits of continuous steel cord technology in preventing track breakage. ↩︎

7. Information on international standards for material testing and quality reporting. ↩︎

8. Technical specifications for floating seals used in heavy equipment and rollers. ↩︎

9. Overview of high-durability rolling bearings used in heavy-duty machinery. ↩︎

10. Importance of pressure testing for ensuring the integrity of sealed mechanical parts. ↩︎