Searching for suppliers online

When it comes to selecting undercarriage parts for your excavator 1, providing specific details about your work conditions is crucial. The more detailed and accurate your description, the better your supplier can tailor the parts to match your operational needs.

Your supplier should be informed about ground material, typical operating hours, and environmental factors to recommend suitable parts that endure your work conditions.

Here's how you can effectively communicate your work environment.

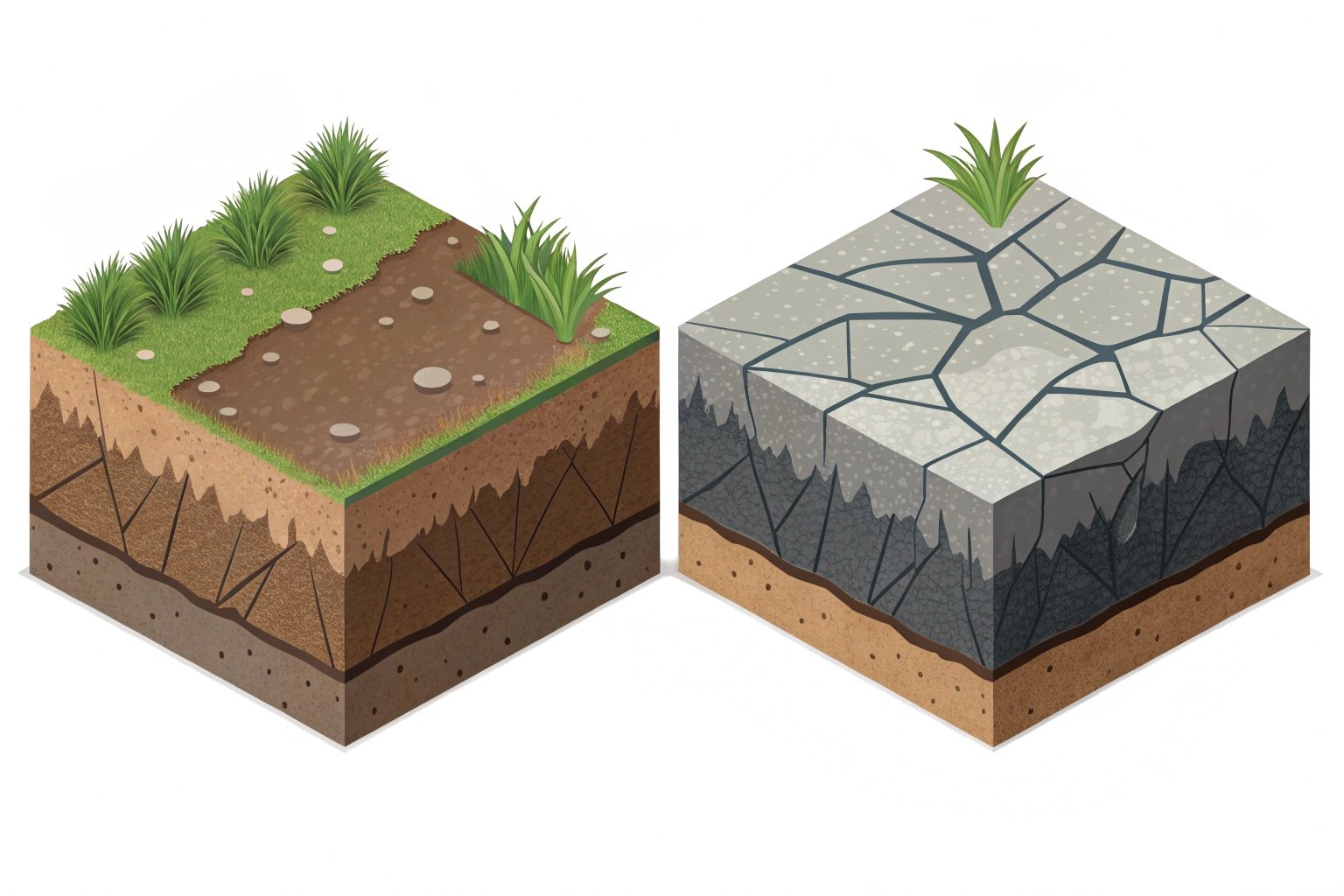

What information about the ground material (e.g., abrasive rock, soft soil) is most helpful for them?

The type of ground material directly impacts the wear and tear on undercarriage components 2.

Share specifics like operating on abrasive rock versus soft soil. Tailored parts for rocky terrains minimize excessive wear, while softer soils might favor different designs.

Ground material details

- Abrasive Rock: Requires high-durability parts like hardened track shoes 3.

- Soft Soil: Favors parts with good floatation to prevent sinking 4.

- Mixed Terrain: May need versatile track designs for adaptability.

Ground material considerations

| Material Type | Requirements | Part Adaptation |

|---|---|---|

| Abrasive Rock | High durability | Hardened components |

| Soft Soil | Good floatation | Wider tracks |

| Mixed Terrain | Versatility | Hybrid solutions |

Should I mention the typical operating hours and load factors for my machines?

Suppliers can recommend parts better suited to your working hours and load conditions by knowing these elements.

Yes, discussing operating hours and load factors helps tailor parts for optimal longevity and performance under your specific demands.

Operational insights

- Daily Operating Hours: Informs on wear life expectations 5.

- Load Patterns: Helps in selecting components that can handle specific stresses 6.

- Work Cycles: Determines the structural resilience of parts 7.

Operational details

| Factor | Impact | Recommendation |

|---|---|---|

| Operating Hours | Wear life | Durable materials |

| Load Factors | Stress resistance | Reinforced design |

| Work Cycles | Fatigue management | Long-lasting components |

Can I ask if they have a heavy-duty or extreme-service version of their standard parts?

Seeking out heavy-duty or extreme-service options 8 tailors part selection to challenging environments.

Absolutely, inquire about heavy-duty or extreme-service parts. These variants are designed to endure harsher conditions, enhancing performance and reducing failures.

Importance of service versions

- Heavy-Duty Versions: Built for longevity in high-stress conditions.

- Extreme-Service Parts: Offer superior resistance to wear and environmental factors.

- Custom Fit: Specific for unique operational challenges.

Variants comparison

| Version | Ideal Use | Performance |

|---|---|---|

| Heavy-Duty | High intensity | Extended life |

| Extreme-Service | Challenging environments | Maximum durability |

| Standard | Regular use | Basic performance |

How can their recommendation help me avoid premature wear and failure?

Supplier insights assist in choosing parts specifically tailored to avoid common failure modes 9 under your work conditions.

Their recommendations help prevent premature wear by aligning part specifications with your operational realities, extending component life and efficiency.

Preventative insights

- Material Selection: Based on environmental factors.

- Design Developments: To combat specific wear patterns.

- Usage Alignment: Ensures the right component for the right job.

Recommendation benefits

| Aspect | Solution | Benefit |

|---|---|---|

| Material Choice 10 | Environmental adaptation | Minimized wear |

| Design Features | Address wear patterns | Improved longevity |

| Usage Matching | Task specificity | Enhanced durability |

Conclusion

A comprehensive detailing of work conditions helps ensure that the undercarriage parts you select will be suitable for your operations. By engaging with your supplier accurately, you gain access to the most suitable parts that endure your specific environment and usage patterns.

Footnotes

1. A guide to the components of an excavator undercarriage. ↩︎

2. Analysis of common wear patterns on heavy equipment undercarriages. ↩︎

3. Explore the benefits and manufacturing process of hardened track shoes. ↩︎

4. Explaining the engineering principle of floatation in heavy machinery. ↩︎

5. Industry benchmarks and estimations for component wear life. ↩︎

6. Learn how machine load patterns can induce specific component stresses. ↩︎

7. Understanding engineering principles behind structural resilience in parts. ↩︎

8. Comparison of standard vs. heavy-duty undercarriage part specifications. ↩︎

9. A practical guide to identifying and preventing common equipment part failures. ↩︎

10. The role of material choice in manufacturing durable heavy equipment parts. ↩︎