Evaluating a supplier's quality control (QC) system is critical to ensuring that the undercarriage parts you receive meet high standards of reliability and performance 1. This starts from examining their processes for raw material acquisition through to shipping protocols 2.

Focus on verifying certifications, quality procedures, and monitoring practices at each stage of production to ensure comprehensive quality assurance.

Below are some steps and questions to guide your assessment.

What questions should I ask about their incoming raw material inspection process?

Understanding raw material checks helps ensure that the foundation of the parts' quality is sound.

Ask about the specific tests and certifications required, and how non-conforming materials are handled upon arrival.

Key questions to ask

- What analysis reports 3 accompany each delivery of materials?

- How often are chemical compositions verified 4 against specifications like 40Mn2, 50Mn?

- What procedures are in place for handling non-compliant materials?

Raw material verification

| Inquiry | Importance | Verification |

|---|---|---|

| Analysis Reports | Ensures base quality | Insist on test documentation |

| Composition Checks | Confirms specifications | Regularity of tests |

| Handling Non-Compliance | Quality assurance | Defined procedures |

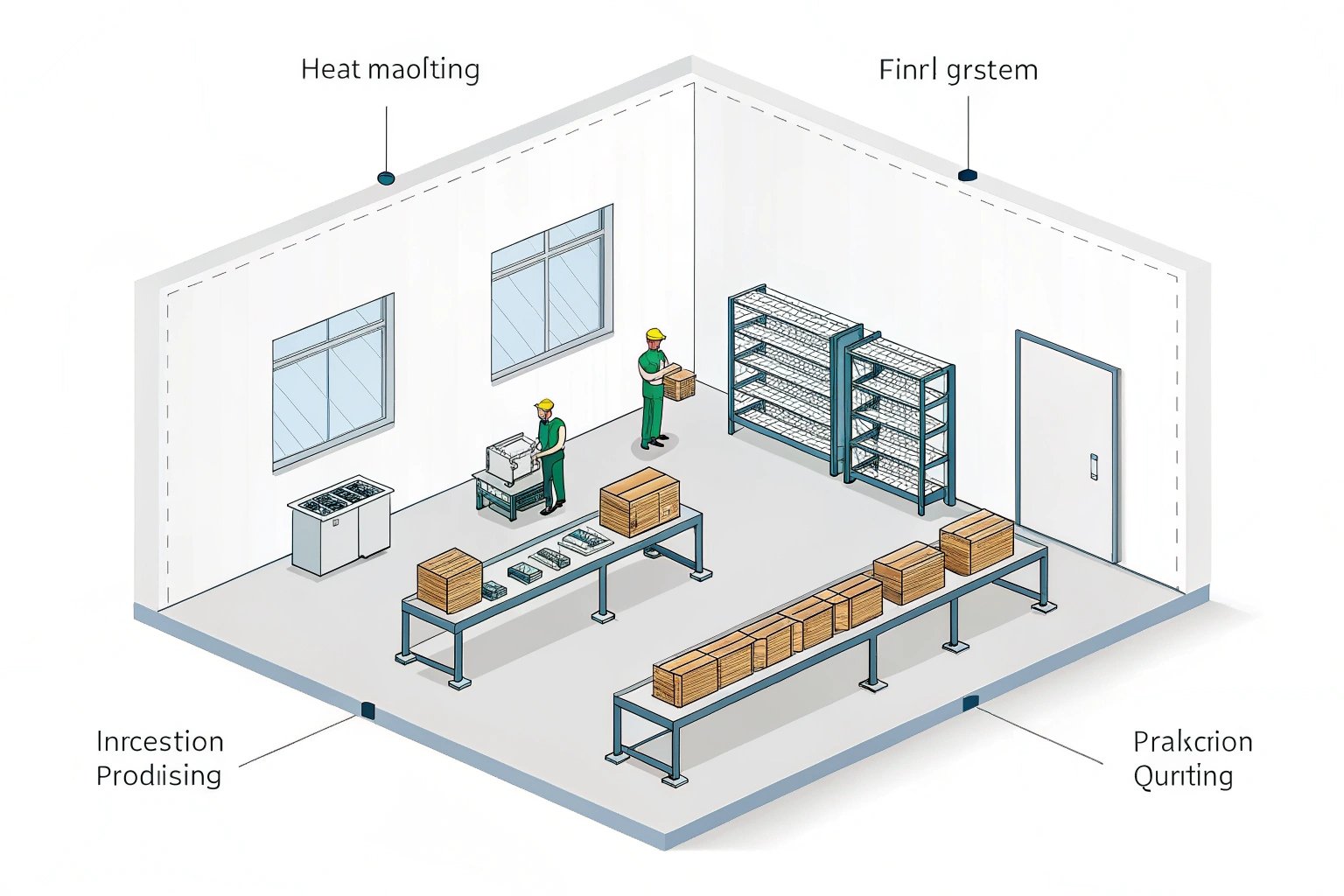

How do they ensure quality control at each stage of the production line?

Continual monitoring throughout the production process is crucial for maintaining quality.

Investigate their in-process inspections and checks to ensure errors areidentified early on.

Production control insights

- What checkpoints exist during forging, casting, or machining?

- Are there documented protocols for monitoring heat treatment cycles 5 and dimensions?

- Is there routine calibration of machines 6 and tools?

Stage-wise monitoring

| Stage | Control Method | Impact |

|---|---|---|

| Forging/Casting | Temperature and form checks | Prevents defects |

| Heat Treatment | Hardness testing | Ensures durability |

| Machining | Dimensional checks | Matches design |

Can they show me records of their in-process quality checks and final inspections?

Access to records provides transparency and proof of routine diligence in quality management.

Request documentation proving adherence to QC procedures at each critical stage of production.

Requesting evidence

- Can you provide examples of inspection reports and heat treatment results?

- What are the acceptance criteria for final product inspections?

- Are records accessible for third-party verification 7?

Documentation review

| Record Type | Purpose | Quality Assurance |

|---|---|---|

| Inspection Reports | Process adherence | Proof of diligence |

| Heat Treatment Results | Durability assurance | Verifies standards |

| Acceptance Criteria | Entry threshold | Set quality bar |

How does their QMS handle a non-conforming part found during production?

The response to quality issues indicates the robustness of their Quality Management System (QMS) 8.

Explore their protocols for identifying, documenting, and rectifying non-conforming parts swiftly and effectively.

Corrective process questions

- What steps are taken when a defect is discovered during production?

- Do they maintain records of non-conforming parts and corrective actions?

- How are root cause analysis 9 and prevention mechanisms implemented?

Non-conformance management

| Corrective Action | Procedure | Outcome |

|---|---|---|

| Defect Resolution | Immediate steps | Minimized disruptions |

| Record Maintenance | Documentation | Accountability |

| Preventive Actions | Root-cause analysis | Future avoidance |

Conclusion

Assessing a supplier’s quality control system from raw materials to final shipping involves a thorough review of their processes, certifications, and documentation practices 10 to ensure the consistent delivery of high-quality undercarriage parts.

Footnotes

1. Learn about setting industrial reliability and performance benchmarks. ↩︎

2. Best practices for final inspection and shipping protocols. ↩︎

3. Guide to understanding material analysis and test reports. ↩︎

4. Overview of chemical composition verification in steel manufacturing. ↩︎

5. Importance of monitoring heat treatment cycles for part durability. ↩︎

6. Why routine calibration of manufacturing machinery is essential. ↩︎

7. Role of third-party verification in confirming supplier claims. ↩︎

8. What a Quality Management System (QMS) includes. ↩︎

9. Techniques for effective root cause analysis in manufacturing. ↩︎

10. Guide to best practices in quality control documentation. ↩︎