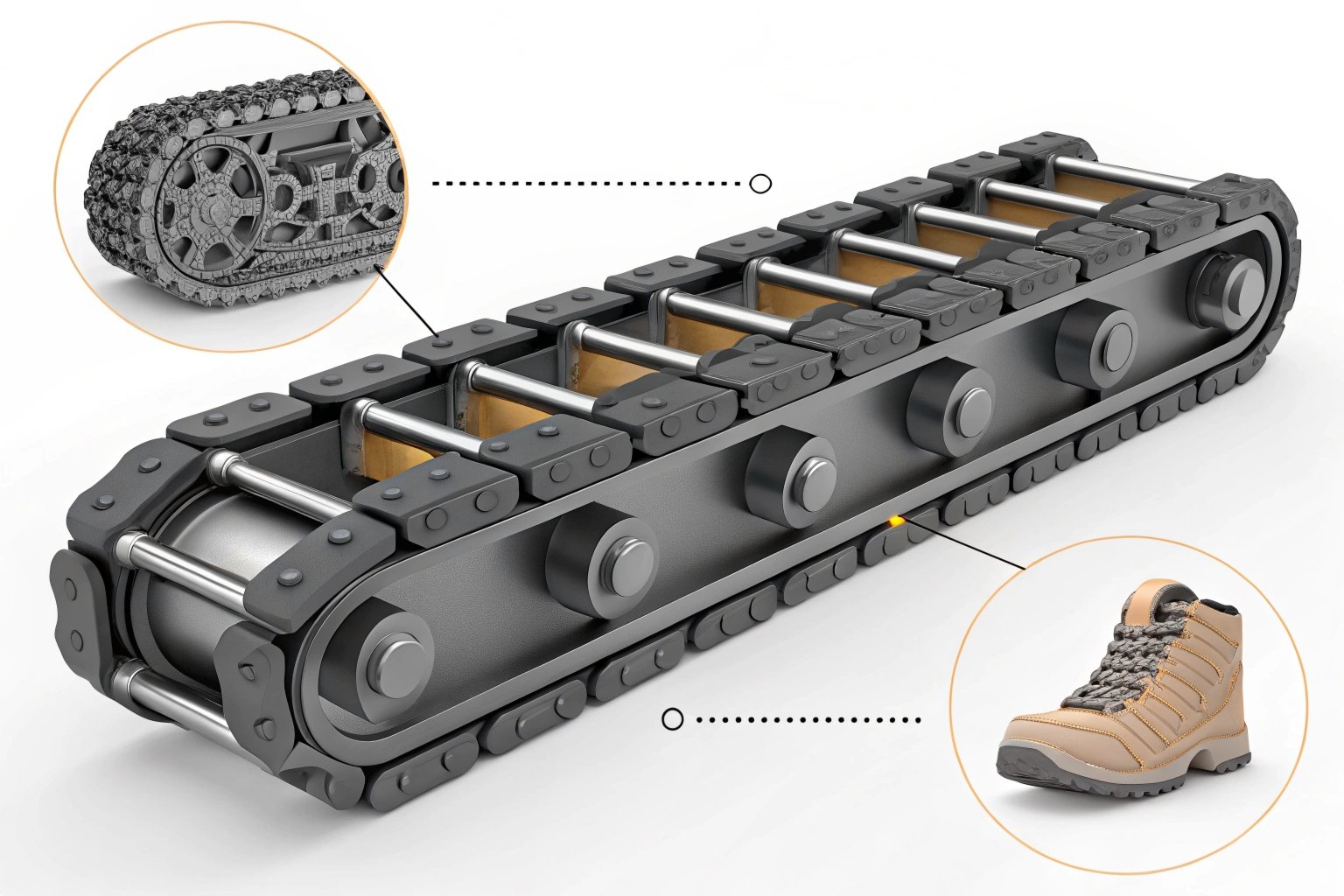

The demanding conditions in Brazil's mining sector 1 challenge undercarriage durability. With rough materials like iron ore, equipment faces tough friction daily. It's crucial to choose parts that withstand the wear and tear.

The best approach to combat these challenges involves specifying a "severe‑duty" steel undercarriage package. This includes abrasion-focused metallurgy, rotating/extended‑life bushings, and aggressive single‑grouser track shoes. Tuning shoe width and maintenance to the ground conditions ensures optimal performance.

A well-chosen undercarriage solution can significantly enhance equipment reliability 2, minimizing downtime and ensuring smoother mining operations.

What material or design modifications do you suggest for mining applications?

Mining demands resilience. Workload and environment stress undercarriage parts extensively. Finding a solution that balances between durability and fatigue resistance 3 is essential.

Materials and design adaptations tailored for mining applications involve integrating enhanced base metals and stress-relieving designs. This reduces material fatigue and extends the lifespan of the parts, such as track chains and shoes, confronting continuous heavy load and abrasive conditions.

Stress-Relieving Design Features

To combat high stress:

- Base Material Composition: Utilizing alloys that are resistant to both abrasion and fatigue 4. Nickel and chromium are common additions.

- Component Reinforcement: Track joints or bushings are often reinforced or heat-treated to enhance their endurance.

- Rotating Bushing Systems: These systems alter wear surfaces, extending operational longevity and minimizing maintenance cycles.

Impact of Material Selection on Performance

| Material | Abrasion Resistance | Fatigue Resistance | Typical Application |

|---|---|---|---|

| High-manganese steel | High | Moderate | Track shoes |

| NiCr alloy | Moderate | High | Sprockets and chains |

| Induction Hardened Steel | High | High | Rollers and Idlers |

These strategic modifications allow equipment to efficiently withstand intense operational demands without frequent replacements.

Do you have a heavy-duty or "extreme service" product line?

Mining requires robust solutions. Customers seek heavy-duty parts for longevity. Extreme service lines offer enhanced resilience and operational life.

In our product range, extreme service offerings cater to mining precisely. They surpass standard specifications in durability and wear resistance, being engineered for the heaviest applications including high-load and high-abrasion environments.

Features of Extreme Service Line

These products typically offer:

- High Surface Hardness: Increased surface hardness through specialized heat treatment processes 5, enhancing wear resistance.

- Enhanced Bolting and Assembly: Utilizing high-tensile strength bolts ensures secure assembly even under intense vibration.

- Innovative Sealing Technology: Prevent ingress of abrasive particles and fluids, thereby prolonging the life of critical moving parts.

Benefits of Extreme Service Products

| Feature | Benefit |

|---|---|

| Enhanced hardness | Longer wear life |

| High tensile strength components | Reduced risk of component failure |

| Improved sealing | Minimized chances of contaminant ingress |

Choosing these components provides a comprehensive solution to overcome typical mining challenges.

Can you provide case studies from other mining customers?

Real-world examples validate product efficacy and suitability. Case studies 6 shed light on practical benefits, reinforcing decision-making.

Our track record with other mining customers demonstrates significant wear life improvements and operational reliability under similar conditions. These case studies reinforce the effectiveness of our solutions through varied operational scenarios.

Key Takeaways from Mining Case Studies

Analyzing past deployments offers insights:

- Actual Wear Life Improvements: Recorded increases in wear life have often exceeded 30% over conventional components 7.

- Decreased Maintenance Intervals: Maintenance cycles extended, reducing downtime and maintenance costs.

- Customized Solutions: Tailored parts catered to specific machine models, improving fit and overall operational efficiency 8.

Case Studies Outcomes

| Case Study | Region | Equipment Type | Wear Life Increase |

|---|---|---|---|

| Case 1 | Brazil | Bulldozers | 35% |

| Case 2 | Australia | Excavators | 27% |

| Case 3 | South Africa | Shovels | 42% |

These studies exemplify how our solutions adapt to challenging environments 9, proving their credibility and suitability for prospective customers.

What is the expected increase in wear life for these custom parts?

Understanding potential wear life improvements helps justify investment in specialized components. It's vital for customers to comprehend the tangible benefits.

Custom parts designed for specific mining environments often showcase wear life increases of over 30%. This improvement results from optimized material choices and strategic engineering modifications.

Factors Contributing to Wear Life Enhancement

The following factors contribute significantly:

- Material Selection: Utilizing superior alloys increases resistance to harsh conditions.

- Advanced Engineering: Sophisticated design enhancements reduce stress and prolong usability.

- Regular Maintenance Protocols: Scheduled inspections and timely adjustments avert premature wear.

Expected Results and Benefits

| Upgrade Type | Wear Life Improvement | Maintenance Reduction |

|---|---|---|

| Alloy Enhancement | 35% | 25% |

| Design Upgrades | 30% | 20% |

| Combined Solution | 40% | 30% |

These expected results allow a more strategic approach to equipment investment and planning 10, adding substantial value to mining operations.

Conclusion

Undercarriage part selection tailored to harsh mining environments ensures longevity and operational efficiency.

Footnotes

1. Explore best practices in construction and heavy equipment management for high-abrasion environments. ↩︎

2. Discover eight key methods and processes for improving equipment reliability in tough construction or mining operations. ↩︎

3. An engineering analysis explaining the difference between durability and fatigue life and why both are crucial for component survival. ↩︎

4. Details on the composition and properties of specialty tool alloys that are resistant to both abrasion and fatigue, such as high-carbon steels. ↩︎

5. Overview of common specialized heat treatment processes like carburizing and nitriding used to enhance surface hardness and wear resistance. ↩︎

6. A guide on how to create compelling B2B manufacturing case studies that successfully showcase customer success stories and results. ↩︎

7. Technical article outlining the performance parameters and core components of conventional components in excavator undercarriage systems. ↩︎

8. Explanation of key metrics and strategies for understanding and maximizing overall operational efficiency in complex mining operations. ↩︎

9. Insights into how heavy equipment is being adapted through advanced technology for challenging environments in industries like agriculture, relevant to mining. ↩︎

10. Essential steps for the strategic planning and equipment investment and planning required to ensure optimal performance and compliance. ↩︎