My machine is down, and I'm unsure how to install this new roller. Waiting for a local tech costs time and money. I need expert help from my supplier right now.

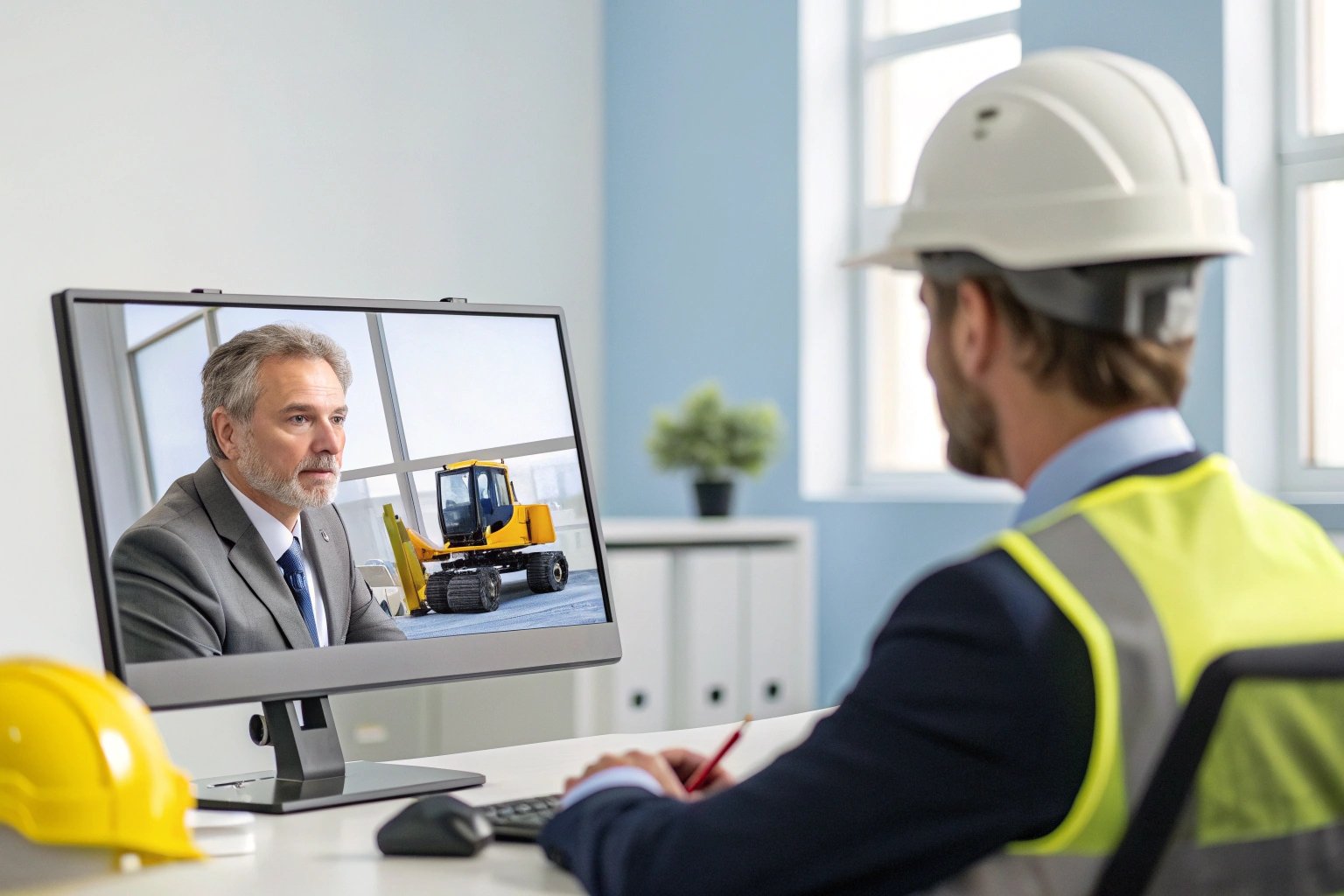

Yes, many high-quality undercarriage parts suppliers offer remote technical support. This often includes video calls for installation guidance, email support for troubleshooting, and access to online technical manuals. Reputable manufacturers (like us at Dingtai) see this as a key part of their service.

But getting support isn't just about if they offer it. As a purchasing director like David, I know the quality of that support matters. You need to know if they speak your language, how fast they respond, and what tools they use. Let's look deeper into what real support means.

Do they have English-speaking engineers or technicians available to help?

I worry that my supplier won't understand my technical problem. Explaining "excessive play in the idler" 1 is hard enough. Miscommunication can lead to installing the wrong part or voiding a warranty.

Yes, global suppliers (like Dingtai) serving markets like North America and Europe must provide English-speaking technical support. This is essential for B2B partners. This support should come from actual engineers or experienced technicians, not just sales staff, to ensure technical accuracy.

The availability of English-speaking support is a critical factor when choosing a global parts supplier 2. For a purchasing manager in the US, clear communication is not a luxury. It is a basic requirement for business.

Why Sales Support is Not Enough

Many suppliers claim to have "English support," but this often means the sales team. A salesperson can take an order. They cannot diagnose a problem with a track tensioner 3 or explain the torque specifications for sprocket bolts 4.

As someone who manages equipment maintenance (like our client David), you know the details matter. You need to ask suppliers specific questions:

- Is your technical support team separate from your sales team?

- Are the technicians fluent in technical English 5 (e.g., metallurgy, hydraulics, assembly)?

- What are their hours of operation? (This is crucial with time zone differences).

At Dingtai, we learned this early. Our technical team works closely with our export sales team. When a technical question comes in, it is routed directly to an engineer. This engineer can pull up the exact CAD drawing for your part.

The Risk of Miscommunication

Miscommunication in technical details leads to costly errors. For example, a customer might describe a "wobble" in a roller. A non-technical salesperson might just send a replacement. An engineer, however, will ask:

- Is the wobble lateral (side-to-side) or vertical?

- Can you send a video of the movement?

- What is the operating environment 6? (e.g., rocky, sandy)

This level of questioning, in clear English, can quickly determine if the issue is a failed bearing, an installation error, or simply normal wear. This prevents the cost of shipping a part that was not needed.

Evaluating a Supplier's Language Capability

Before placing a large order, test their support. Send a technical email inquiry. Do not send it to sales. Send it to their "support" or "info" address. See who responds and how clear their answer is.

Here is a simple comparison of support types:

| Support Type | Who Answers? | Effectiveness (Technical Issues) |

|---|---|---|

| Basic Sales Support | Salesperson | Low. Good for order taking, bad for diagnostics. |

| Translated Support | Salesperson + Internal Translator | Medium. Slow, and details get lost in translation. |

| Dedicated Technical Support | English-speaking Engineer | High. Fast, accurate, and builds trust. |

A supplier serious about the global market invests in bilingual engineers 7. They understand that clear communication is the foundation of long-term trust and partnership.

What is the best way to contact them for urgent technical support (e.g., email, video call)?

My excavator is stuck in the mud, and the track just snapped. This is an emergency. I can't wait 48 hours for an email response. I need to know the fastest way to get help.

The best method depends on the urgency. For urgent issues (like a machine down), a direct video call or a dedicated app (like WhatsApp or WeChat) is fastest. For non-urgent diagnostics or part verification, email is better as it creates a written record.

When a machine is down, every minute counts 8. A $500,000 excavator standing idle can cost thousands of dollars per day in lost productivity. The supplier's contact method for urgent support is a key part of their value.

Matching the Tool to the Problem

Not all problems are an emergency. A good supplier (like us at Dingtai) offers different channels for different needs.

- Email: This is the standard for non-urgent communication. It is perfect for asking for documentation, clarifying part numbers, or reporting a non-critical issue. It creates a paper trail. This is excellent for tracking solutions and warranty claims 9.

- Phone/Video Call: This is for urgent issues. When a part arrives and the installation is confusing, a video call is best. The technician can see the problem. They can guide the mechanic in real-time. For example, they can say, "Stop. The bolt alignment is incorrect. Look at this diagram."

- Instant Messaging (WhatsApp/WeChat): This is often the fastest method. It combines the speed of a call with the clarity of sending photos and videos. A mechanic can send a 10-second video of an unusual noise from a roller. The engineer can review it and respond immediately.

The Power of Video Diagnostics

As a manufacturer, we find video essential. It removes guesswork. A customer might say, "The track roller is leaking." This could mean many things.

A short video can show:

- Where the leak is coming from (e.g., the seal, the plug).

- The color and viscosity of the oil.

- The condition of the surrounding parts.

Based on this video, an engineer can diagnose the problem 80% of the time without ever visiting the site. This saves the customer (like David) from having to ship the part back for inspection.

Setting Clear Expectations

A professional supplier will define these contact methods clearly. They should provide a dedicated support email and a direct contact (like a WhatsApp Business number) for urgent after-sales support. If a supplier only gives you a general "sales@" email, this is a red flag. They may not be prepared for real technical support.

Can they provide installation manuals or technical bulletins for their products?

I just received a pallet of new track chains, but there are no instructions. Am I supposed to guess the correct procedure? Installing it wrong could destroy the part and my reputation.

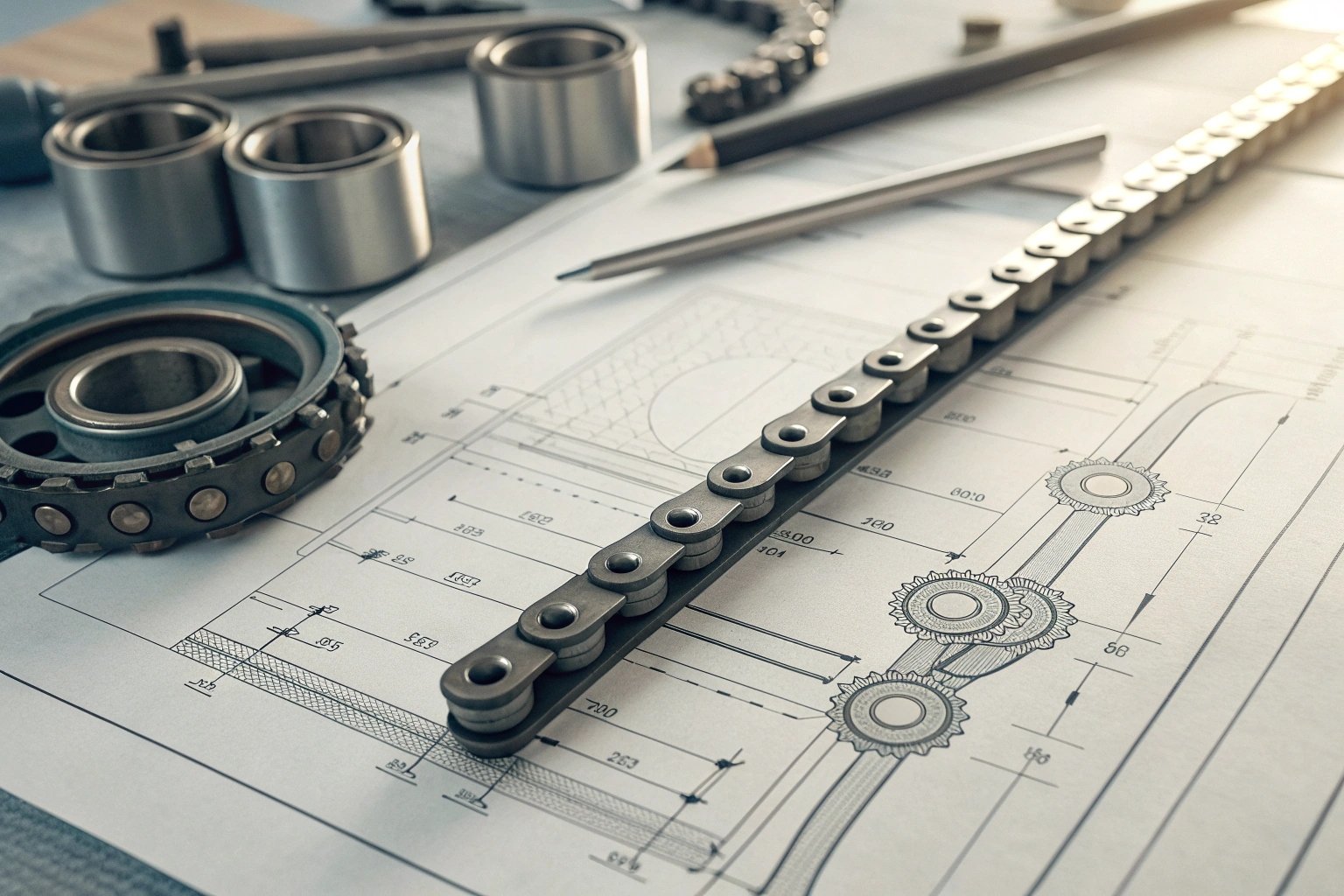

Yes, a reliable OEM supplier (like Dingtai) must provide comprehensive documentation. This includes detailed installation manuals, technical specification sheets (with material data), and bulletins on product updates. This documentation ensures safety, correct installation, and validates the quality of the part.

Documentation is not just a piece of paper. It is a core part of the product. For a technical buyer like David, seeing a detailed manual 10 is as important as seeing the part itself. It shows the supplier is professional and understands their own product.

What to Expect in a Good Manual

A simple "how-to" guide is not enough. Professional technical documentation for undercarriage parts should include:

- Clear Diagrams: Exploded views showing every bolt, seal, and component.

- Part Numbers: Clear labeling of all components.

- Tool Lists: The specific tools needed for the job.

- Step-by-Step Procedures: Written in plain English.

- Technical Specifications: This is the most important part.

Critical Technical Specifications

The specifications section is vital for a correct and safe installation. It prevents damage to the part and the machine.

| Specification | Why It Is Critical |

|---|---|

| Bolt Torque Values | Prevents bolts from becoming loose (too little torque) or breaking (too much torque). |

| Track Tension (Sag) | Incorrect tension is the #1 cause of premature wear on all undercarriage parts. |

| Material Hardness (HRC) | Confirms the quality and durability of wear surfaces (e.g., roller shell, track link). |

| Lubrication Type | Ensures the internal bearings and seals are protected. |

Technical Bulletins and Wear Guides

The industry also changes. Sometimes, an OEM (like Caterpillar or Komatsu) updates a procedure. A good aftermarket supplier (like us at Dingtai) will issue a technical bulletin to their distributors (like David) explaining this change.

Furthermore, documentation can help with diagnostics. A common question we get is about wear. A customer sends a photo of a sprocket and asks if it needs replacement. A good supplier can provide a "Wear Guide" bulletin. This guide shows pictures of acceptable wear versus critical wear. This empowers the customer to make their own decisions and saves time.

When we work with long-term partners, we often create customized documentation packets that match their specific stock lists.

How responsive are they to technical inquiries?

I sent an urgent email about a leaking final drive seal three days ago. I have heard nothing back. My machine is still down, and my customer is furious with me.

Responsiveness is a key performance indicator. A good supplier (like us at Dingtai) should acknowledge an urgent technical inquiry within hours, not days. They should aim to provide a complete solution or diagnostic path within one business day (24 hours), managing time zone differences effectively.

In the B2B world, "time is money" is not a cliché. It is a fact. Responsiveness is often more important than the initial purchase price. A cheap part with no support is extremely expensive when it fails.

Defining "Responsive"

"Responsive" means two things:

- Speed of Acknowledgment: How fast they say, "We received your problem and are working on it."

- Speed of Resolution: How fast they provide a solution.

For a distributor like David, supporting his own customers depends entirely on the supplier's responsiveness. If his supplier (like us at Dingtai) is slow, he looks slow to his customers. This damages his reputation.

The 24-Hour Rule

Because we manufacture and sell globally, we operate on a 24-hour cycle. A technical question from the USA or Europe (like David's) often arrives during our night. Our support system is designed to ensure that when our engineers arrive in the morning, that ticket is their first priority.

The goal is always to provide a meaningful response within 24 hours. This is especially critical for remote job sites where every hour of downtime is a major loss.

Building a System for Responsiveness

Good responsiveness is not an accident. It comes from a good system.

- Dedicated Support Channel: A specific email or portal for support, not the general sales inbox.

- Ticket System: Logging every inquiry to ensure it does not get lost.

- Linking Support to Order History: When a customer contacts us, our system should immediately show us their order history. We do not need to ask, "What part number did you buy?" We already know. We can pull the specs instantly.

Response Time Expectations

| Inquiry Type | Ideal Acknowledgment Time | Ideal Resolution Time |

|---|---|---|

| Urgent (Machine Down) | < 1 hour (via phone/video) | < 4 hours (diagnostic path) |

| Technical Question (Non-Urgent) | < 8 business hours | < 24 business hours (full answer) |

| Documentation Request | < 4 business hours | < 8 business hours (send files) |

A supplier who cannot meet these basic standards is not a reliable long-term partner. They are just a vendor.

Conclusion

As a manufacturer (Linda at Dingtai), I believe support is not optional. It is the product. We are ready to prove it.

Footnotes

1. Detailed guide on diagnosing and fixing idler problems in excavators. ↩︎

2. Article on key factors for evaluating international heavy equipment parts suppliers. ↩︎

3. Video showing how a track tensioner works and its internal components. ↩︎

4. Resource explaining the importance of proper bolt torque in heavy machinery assembly. ↩︎

5. White paper on the necessity of technical fluency for global B2B partnerships in manufacturing. ↩︎

6. Study on the impact of different operating environments on undercarriage wear life. ↩︎

7. Best practices for companies leveraging bilingual engineers in a global supply chain. ↩︎

8. Case study demonstrating the high cost of industrial downtime for heavy machinery. ↩︎

9. Guide to establishing clear procedures for warranty claims and solution tracking. ↩︎

10. Checklist for comprehensive technical documentation for heavy equipment parts. ↩︎