Navigating the options for bulldozer track chains can be confusing. I know the importance of choosing the correct type for longevity and performance.

Our bulldozer track chains come in both "dry" and "sealed and lubricated" (greased) varieties. Dry chains are cost-effective but require more maintenance. Sealed and lubricated chains, with a built-in lubricant reservoir, offer longer service life and lower upkeep in demanding conditions.

But which type is best suited for your specific needs? Read on to learn more.

Do you offer both types of track chains?

Making the right choice between track chains can be daunting. Are you leaning towards dry track chains 1, which may seem budget-friendly initially, or sealed chains offering longevity?

Indeed, we provide both dry and sealed and lubricated track chains to meet diverse needs and budgets. Dry chains operate without a lubrication reservoir, whereas sealed chains minimize wear with built-in grease or oil.

Key Differences Between Chain Types

Table: Chain Type Comparison

| Feature | Dry Chains | Sealed and Lubricated Chains (SALT) |

|---|---|---|

| Lubrication | External | Internal |

| Maintenance Requirements | High | Low |

| Initial Costs | Lower | Higher |

| Typical Lifespan | Short | Long |

What are the advantages of your sealed and lubricated chains?

Faced with a choice between dry and sealed chains? Exploring the benefits of sealed and lubricated options 2 is essential.

The sealed and lubricated (SALT) chains offer considerable advantages. They feature less wear, longer lifespan, and reduced operational costs, making them especially suited for abrasive environments 3.

Benefits of Sealed and Lubricated Chains

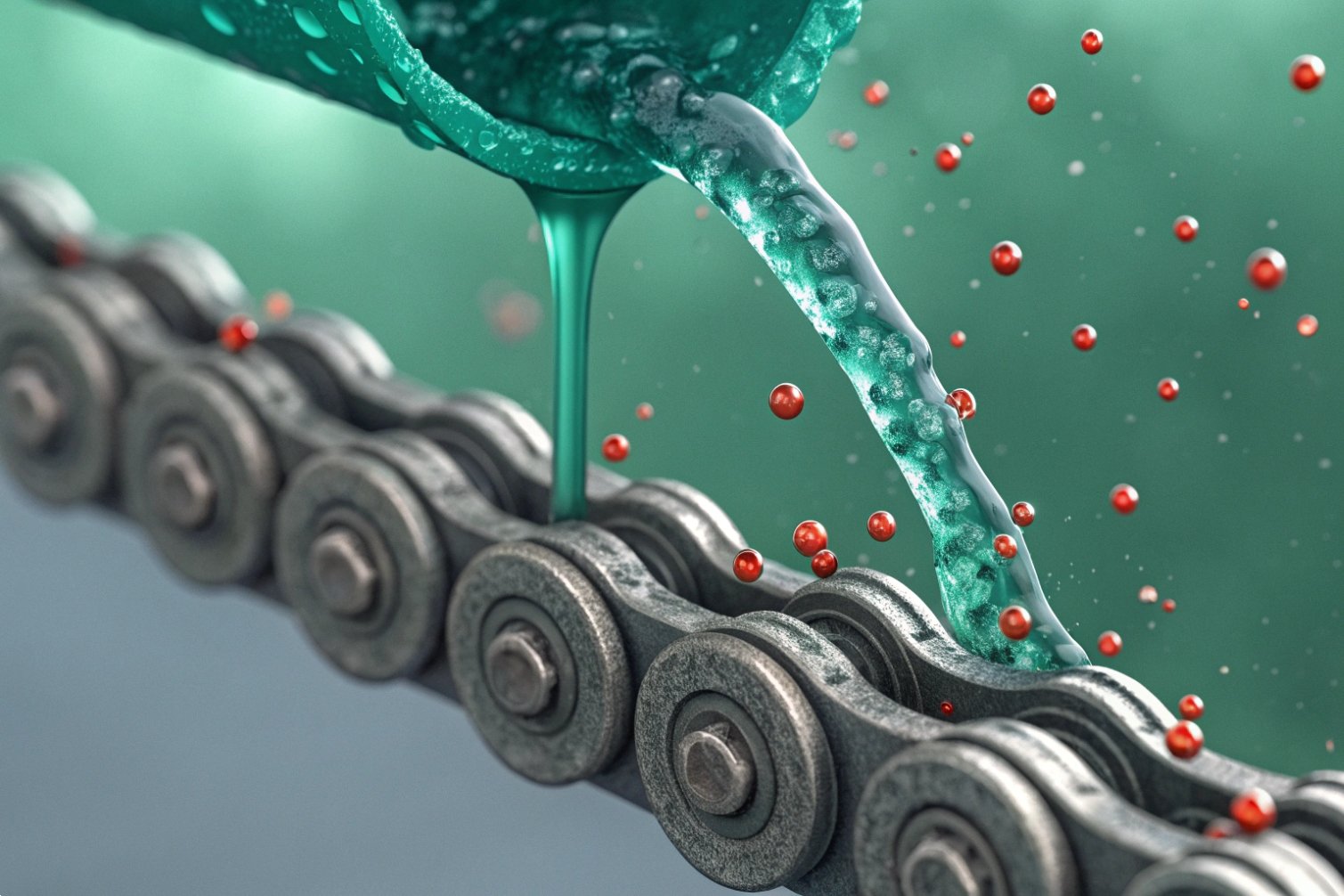

Sealed chains protect their internal joints from contaminants by using rubber seals 4 and keep lubrication intact. This protection allows for reduced friction:

Table: Advantages of SALT Chains

| Advantage | Description |

|---|---|

| Extended Service Life | Minimizes internal wear |

| Lower Maintenance Costs | Less frequent servicing required |

| Improved Performance | Reliable operation in harsh environments |

What type of grease/lubricant do you use?

Ever wondered about the type of lubricant that maximizes track chain efficiency 5? Choosing the correct grease is vital.

Our sealed and lubricated chains use high-grade grease specifically designed for optimal performance in variable conditions. This ensures enduring lubrication 6 suited for diverse climates.

Grease Characteristics

The high-grade grease 7 used in our chains provides consistent lubrication and shields against corrosion:

Table: Characteristics of Our Grease

| Characteristic | Details |

|---|---|

| Temperature Tolerance | Functions well in extreme temperatures |

| Longevity | Maintains lubricating properties over time |

| Corrosion Protection | Prevents internal rust and deterioration |

Which type do you recommend for my applications in Brazil?

Working in the harsh terrain of Brazil 8 requires specialized equipment. Here, chain type selection makes all the difference.

For Brazilian environments, we recommend sealed and lubricated chains. Their durability and low upkeep requirements make them ideal for the abrasive and humid conditions prevalent there 9.

Why Sealed and Lubricated Chains are Ideal

Brazilian settings often involve high abrasion and dust, challenging for machinery. Sealed chains excel by providing reliable lubrication 10 without extra maintenance.

Table: Environmental Suitability

| Environment | Recommended Chain Type |

|---|---|

| High Abrasion Areas | Sealed and Lubricated Chains |

| Dusty Conditions | Sealed and Lubricated Chains |

| Humid Environments | Sealed and Lubricated Chains |

Conclusion

Understanding whether your bulldozer track chains are dry or sealed and lubricated is crucial. Selecting the right type ensures greater efficiency and extended equipment life in varied conditions.

Footnotes

1. See listings and specifications for dry track chains on the Machinery Trader website. ↩︎

2. Explore a detailed article on the advantages of sealed and lubricated undercarriage components. ↩︎

3. Learn about equipment performance in high-abrasion environments from Sandvik's engineering insights. ↩︎

4. Understand the function and material science of rubber seals in heavy equipment applications. ↩︎

5. Read an analysis of how different lubricants impact the operational efficiency of track chains. ↩︎

6. Review ExxonMobil's technical data on long-lasting, high-performance greases for extreme conditions. ↩︎

7. Get detailed information on the chemical composition and standards of high-grade industrial greases. ↩︎

8. Read about the challenges and requirements for mining equipment in Brazil's tough geographical conditions. ↩︎

9. Insights on how to maintain earthmoving equipment and undercarriage components in high-humidity areas. ↩︎

10. Access ASTM standards and research on ensuring reliable lubrication in heavy machinery to reduce wear. ↩︎