When purchasing undercarriage parts for excavators and bulldozers, understanding the minimum order quantity (MOQ) is essential for efficient planning. My experiences and industry knowledge can help clarify the complexities.

Typically, the MOQ for undercarriage parts is flexible, often starting at one piece per item. However, a higher order level is preferred to optimize cost-effectiveness at the shipment level rather than per part number.

Navigating the nuances of MOQ helps businesses 1 like mine in testing product quality and managing inventory efficiently without straining finances.

Is the MOQ Based on a Total Dollar Amount or by the Number of Units per Part?

Determining whether MOQ is set by the total dollar value or the number of units is vital for achieving purchasing efficiency.

Generally, the MOQ is tied to the overall order value rather than specific unit numbers per part. This enables flexibility when combining multiple parts as long as the total reaches efficient shipment value.

Delve into this dynamic to understand the impact of MOQ on order structuring:

- Cost Factors: Ensures profitability for suppliers on small orders.

- Negotiation Leverage: Allows buyers to optimize total value instead of strict unit-based decisions.

- Inventory Management: Facilitates stock control through combined orders rather than fragmented purchases.

These factors underline the importance of strategically planning purchases to meet MOQ effectively 2 while maintaining value.

Considerations Influencing MOQ

Several factors play a role in determining MOQ terms:

| Factor | Impact on MOQ |

|---|---|

| Production Costs | Sets minimum thresholds for affordable production. |

| Inventory Levels | Modifies MOQ depending on stock surplus or deficit. |

| Seasonal Demand | Adjusts MOQ with fluctuations in market demand cycles. |

| Batch Sizes | Influences MOQ decisions based on production runs. |

Understanding these elements can reveal avenues for optimizing MOQ negotiations 3.

Can I Place a Smaller Trial Order to Test Your Quality First?

Testing product quality with smaller trial orders is often advisable, ensuring confidence before larger commitments.

Yes, placing a smaller trial order to test quality is feasible. It allows initial satisfaction assurance before proceeding with larger orders.

Trial orders offer several benefits:

- Risk Mitigation: Reduces financial exposure and helps evaluate product compatibility.

- Quality Validation: Provides a firsthand examination of parts before scaling up.

- Supplier Performance: Tests reliability and capacity to meet targets.

- Customer Feedback: Encourages evaluation and feedback ahead of extensive orders.

The trial order method fosters trust and builds substantive relationships 4 between suppliers and buyers, forming a foundation for future transactions.

Steps for Trial Orders

Here's a concise guide for trial ordering:

| Step | Description |

|---|---|

| Inquiry | Request smaller batch to check quality. |

| Evaluation | Assess components against quality benchmarks 5. |

| Reporting | Offer feedback for improvement and adjustments. |

By employing trial orders, potential risks are minimized, promoting smoother procurement processes 6.

Can I Combine Multiple Different Parts to Meet the MOQ?

Combining different parts to meet MOQ thresholds is often advantageous.

Yes, you can combine various parts to meet MOQ requirements, making it easier to reach efficient shipment values and adjust to specific needs.

Exploration of the practice benefits includes:

- Order Customization: Better matches specific project or inventory demands.

- Cost Efficiency: Balances financial inputs across multiple items.

- Logistical Optimization: Enhances shipment efficiency through consolidated order values.

- Supplier Negotiation: Provides bargaining power in terms of order pacing and constitution.

This approach encourages a synergistic relationship between buyers’ objectives and suppliers’ fulfillment capacities 7.

Combining Parts Strategy

Considerations when combining parts for MOQ:

| Method | Description |

|---|---|

| Mixed Orders | Enables aggregate purchasing across several part categories. |

| Shipment Loading | Utilizes efficient container or pallet strategies 8 for cost-effectiveness. |

| Forecasting | Leverages projection models to determine ideal combined batch sizes. |

Evaluating these strategies supports meaningful engagement with suppliers for more tailored purchasing experiences.

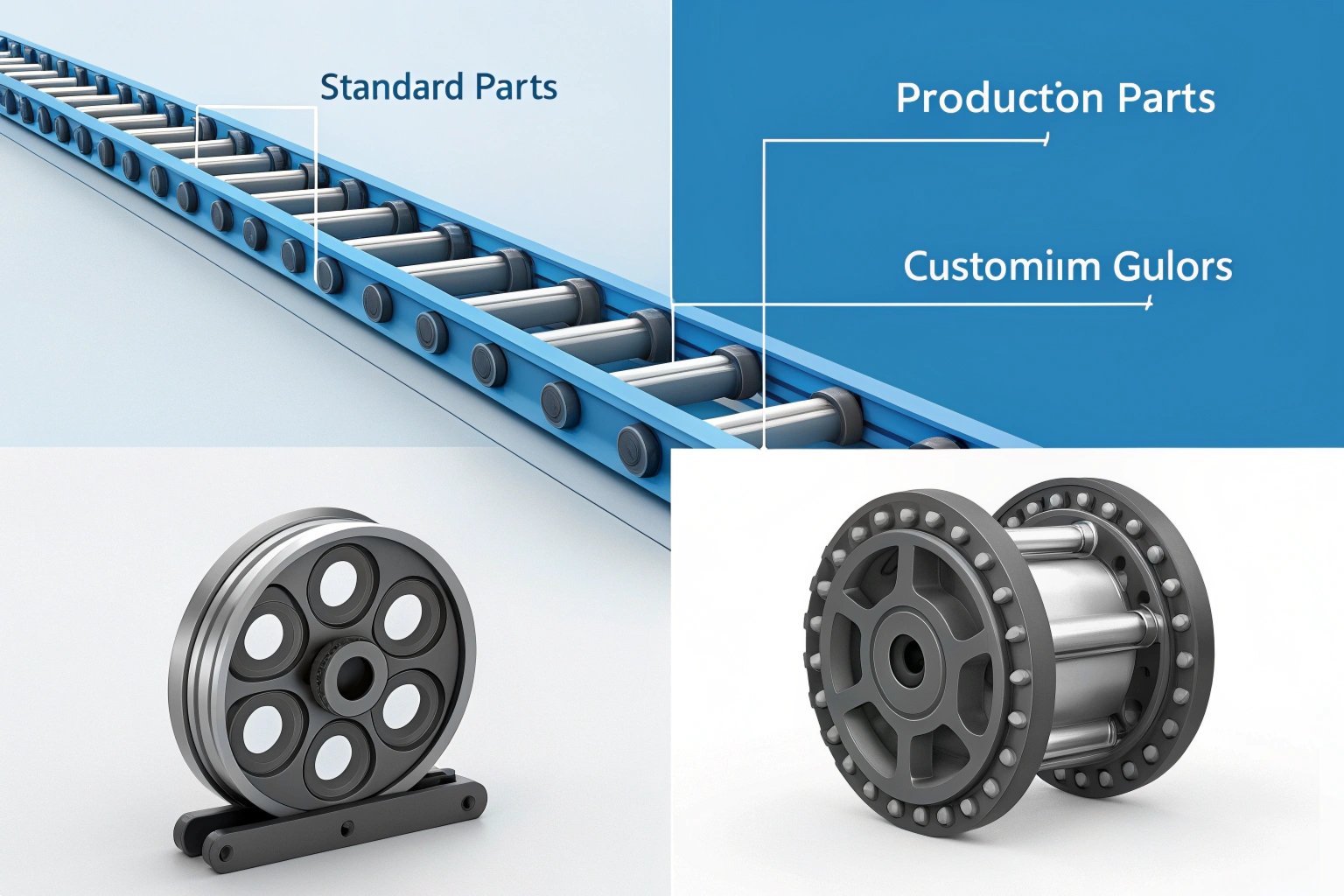

Is the MOQ Different for Standard Parts Versus Custom-Made Parts?

Evaluating the distinction between standard and custom-made parts can affect MOQ determination.

MOQ can differ between standard and custom-made parts. Standard parts usually have lower MOQs, while custom parts might necessitate higher quantities due to complex production needs.

Here’s how these differences typically play out:

- Standard Parts: Broadly accessible with lower MOQs.

- Custom Parts: Require specialized skill and batch efforts, leading to increased MOQs.

- Order Efficiency: Balances immediate purchase needs with longer-term planning.

- Supplier Communication: Engages open dialogues for specificity in part creation.

This distinction informs more nuanced purchasing even for for complex specifications 9 and enhances procurement planning strategies.

Custom and Standard Part Order Planning

Understanding how MOQ varies based on part type:

| Type | MOQ Characteristics |

|---|---|

| Standard Parts | Lower MOQ due to established production workflows. |

| Custom Parts | Higher MOQ geared towards bespoke needs and specialized designs. |

These insights enrich considerations necessary for successfully sourcing the desired manufacturing scope 10.

Conclusion

Thorough comprehension of MOQ ensures effective order planning, enhancing satisfaction and operational efficiency. My insights foster informed decisions and strategic outreach to suppliers regarding MOQ variations for undercarriage parts.

Footnotes

1. Learn about the definition and importance of Minimum Order Quantity (MOQ) in business. ↩︎

2. Guide on calculating and strategizing to effectively meet Minimum Order Quantity requirements. ↩︎

3. View practical strategies and tips for successful Minimum Order Quantity negotiations with suppliers. ↩︎

4. Explore the principles and benefits of Supplier Relationship Management in building business trust. ↩︎

5. Refer to International Organization for Standardization (ISO) for various quality standards and guidelines. ↩︎

6. Understand the steps and significance of the procurement process in managing supply chains. ↩︎

7. Explore the different aspects and strategies involved in supplier order fulfillment capacities. ↩︎

8. Read about optimizing shipment through efficient palletizing strategies for cost-effective logistics. ↩︎

9. Insight into the complexities and considerations when dealing with custom manufacturing specifications. ↩︎

10. Overview of the broad scope and modern landscape of the manufacturing industry today. ↩︎