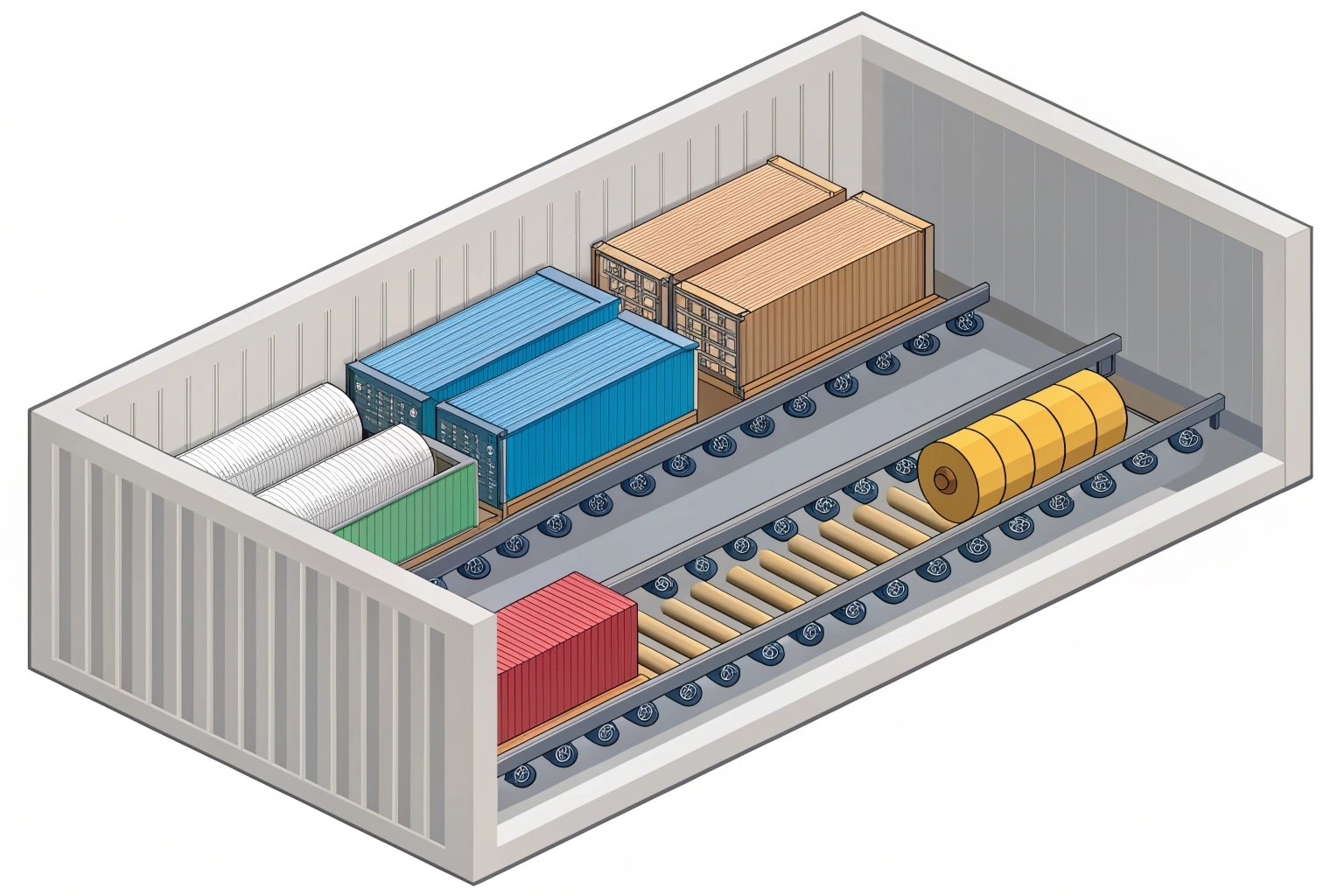

As a purchaser of undercarriage parts, container capacity 1 directly influences transportation expenses. Understanding how many track rollers a container holds enables precise logistics cost calculation and facilitates comparison between different options.

A 20'GP container typically accommodates approximately 750 track rollers, and a 40'HC container can fit around 1,600. These estimates consider effective stacking without additional packaging. Actual numbers may vary due to packing materials.

Grasping the factors affecting container loading efficiency is essential. Packaging methods differ; consult suppliers for packing proposals that balance volume and weight limitations effectively.

Can you provide an estimated weight and CBM for common parts?

Track rollers, being solid metal, pose weight challenges in container loading. Containers must comply with weight limits, 2 requiring both volume and weight considerations in loading calculations.

An individual track roller typically weighs between 20 to 50 kg, influencing the container's weight capacity 3 before volume.

Roller CBM and Weight Details

The following table provides rough CBM and weight specifications for various roller types helpful in planning shipments:

| Roller Type | Diameter (m) | CBM per Roller | Weight per Roller (kg) |

|---|---|---|---|

| Small | 0.15 | 0.006 | 20 |

| Medium | 0.20 | 0.008 | 35 |

| Large | 0.25 | 0.010 | 50 |

Balancing Weight and Space

- Packaging Influences: Consider crate versus pallet 4 space implications.

- Stacking Orientation: Determine optimal flat versus vertical placements.

- Supplier Coordination: Constant dialogue ensures packing method alignment with physical constraints.

What is the average weight of a full container of track rollers?

Full container weight 5 knowledge is crucial for logistical planning, averting theoretical projections that overlook practical constraints.

A fully loaded 20'GP container accommodates up to 25 tons of rollers, adjusting for packaging influence, while a 40'HC container typically holds around 50 tons.

Container Weight Limit Guidance

Here is a simplified guide showing maximum payload estimates for different container types, aiding verification:

| Container Type | Max Payload (tons) | Roller Quantity Estimate |

|---|---|---|

| 20'GP | 25 | 1,000 |

| 40'HC | 28 | 2,200 |

Strategic Planning

- Periodic Validations: Scrutinize shipping limitations 6 prior to final loading phases.

- Adopted Partnerships: Engagement with logistics pros 7 assists in refining weight distribution practices.

Will you help me optimize my container load to save on shipping?

Supplier packaging styles, such as wooden versus pallet solutions, affect total load. Consulting supplier aides in overcoming packing challenges, strategizing mix-loading opportunities 8.

Freight forwarding collaboration 9 advantages bring customized container orientation and capacity optimization strategies.

Enhance Container Packing Strategies

- Efficient Space Utilization: Embed components within available voids strategically.

- Component Mixing Insight: Unlock competitive advantages through smart part blend options.

- Logistic Professional Engagement: Enable informed decision-making through seasoned freight consultation.

Can I mix different parts (e.g., rollers, idlers, tracks) in one container?

Mix-loading benefits 10 unifying shipments efficiently, checking regulation specifics and supplier protocols determine the viability of proposed packing changes.

Considerations for Part Mixing

Here is a table detailing part mixing concerns and practical masterplan possibilities for combined shipments:

| Part Type | Typical Size | Suitable Load Method | Risk Consideration |

|---|---|---|---|

| Roller | Medium | Bulk stacking | Bearing weight |

| Idler | Small | Nesting | Abrasive damage |

| Track | Large | Layering | Shearing risk |

Engage in productive dialogues with suppliers to manage transportation constraints and formulate feasible and strategic consolidation tactics.

Conclusion

Understanding container fitting and improving packing efficiency is pivotal for cost-effective shipping and supply chain optimization.

Footnotes

1. Learn about the standard dimensions and capacity of shipping containers. ↩︎

2. Official guidelines on maximum gross mass for containers in international shipping. ↩︎

3. Detailed information on calculating a container's maximum permissible payload. ↩︎

4. Comparison of shipping crate and pallet options regarding space and protection. ↩︎

5. Real-world data on the typical total weight of a loaded container of heavy parts. ↩︎

6. Importance of verifying compliance with current port and carrier regulations. ↩︎

7. Explore the advantages of hiring professional logistics consultants for shipping. ↩︎

8. Strategies and case studies on combining different products for better container use. ↩︎

9. How freight forwarders can optimize loads and handle complex shipping logistics. ↩︎

10. Overview of the cost and efficiency benefits of consolidating shipments. ↩︎